Preparation method of magnetic mesoporous SiO2 nanoparticles with core-shell-shell structure

A magnetic nanoparticle and magnetic nanoparticle technology, which is applied in the field of preparation of magnetic mesoporous SiO2 nanoparticles, can solve the problems such as invisible pore structure, and achieve clear pore structure, good dispersion, rapid separation and controlled migration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

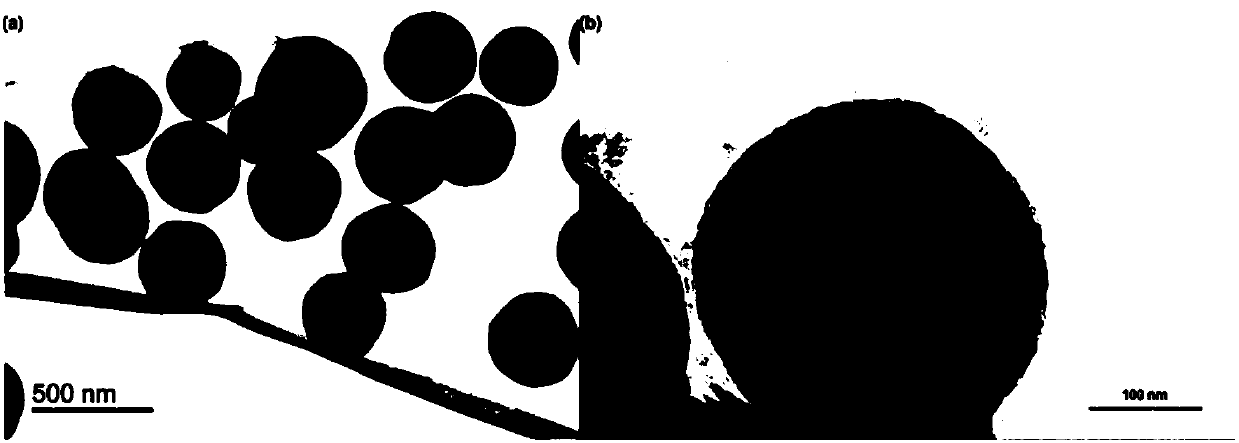

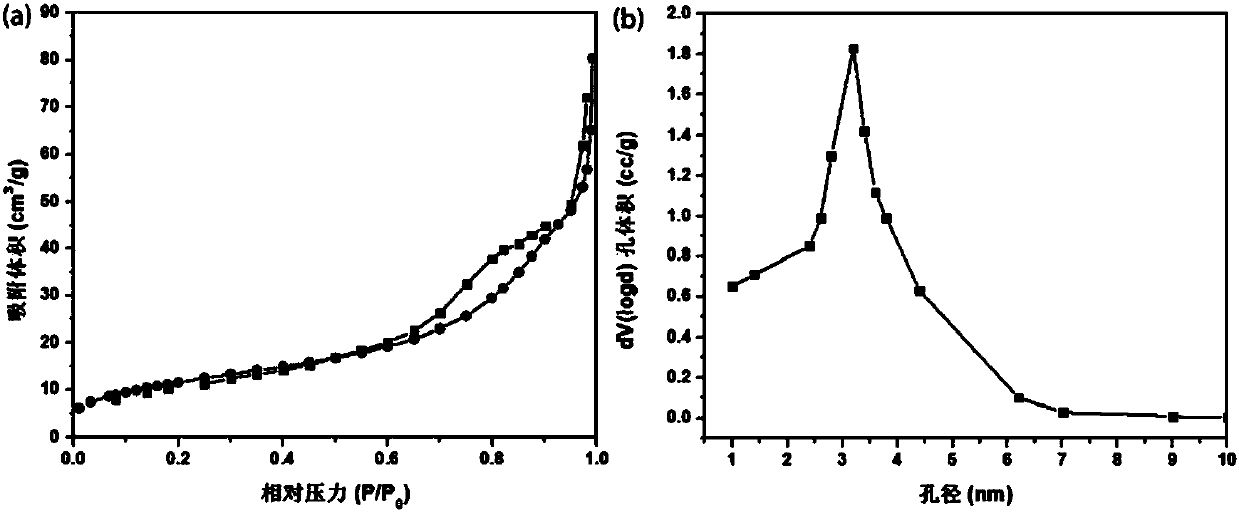

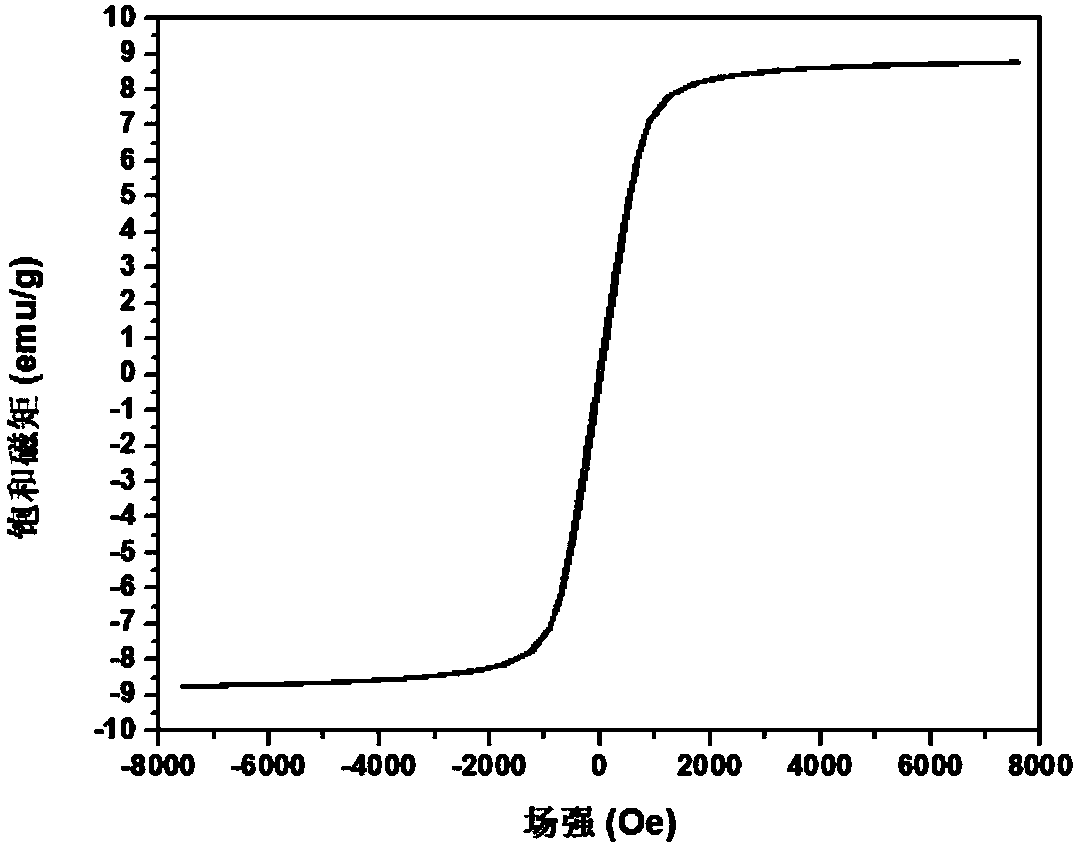

[0020] Embodiment 1: Magnetic mesoporous nanoparticle Fe 3 o 4 @SiO 2 @mSiO 2 - Preparation of EDPS

[0021] Will Fe 3 o 4 Take 100 mg of magnetic nanoparticles and ultrasonically disperse them in a mixture of 160 mL of ethanol and 40 mL of water for 40 minutes, and add 2 mL of NH under vigorous mechanical stirring. 3 ·H 2 O, then add 2.5mL TEOS dropwise within 10min, continue stirring at 35°C for 6h, wash with ethanol and deionized water three times, magnetically separate, and vacuum dry at 40°C for 10h to obtain SiO 2 Coated Fe with uniform size and core-shell structure 3 o 4 @SiO 2 magnetic microspheres.

[0022] Take 80mg Fe 3 o 4 @SiO 2 The magnetic microspheres were dispersed in a mixed solution containing 95mL water, 43mL ethanol, 2.5mL ammonia water and 0.3g CTAC by ultrasonication for 30min. Subsequently, 2.5 mL of TEOS was mixed in 6 mL of ethanol and added dropwise to the reaction system with stirring. After 15 minutes of reaction, the particles were ...

Embodiment 2

[0026] Embodiment 2: large-aperture magnetic mesoporous Fe 3 o 4 @SiO 2 @mSiO 2 - Preparation of EDPS nanoparticles

[0027] Fe 3 o 4 @SiO 2 The preparation method of the magnetic microspheres is the same as in Example 1.

[0028] Take 80mg Fe 3 o 4 @SiO 2 The magnetic microspheres were dispersed in a mixed solution containing 95mL water, 49mL ethanol, 2.5mL ammonia water, 0.18mL triethylamine (TEA) and 0.3g CTAC by ultrasonication for 30min. Subsequently, 2.5 mL of TEOS was dissolved in 6 mL of cyclohexane and added dropwise to the reaction system with stirring. After 15 minutes of reaction, the particles were formed, and 2.5mL EDPS was also added dropwise to the system. After 18 hours of reaction at room temperature, the product was collected by magnetic separation and washed three times with ethanol and water. Finally, the nanoparticles were redispersed in 60 mL of acetone, and refluxed at 70 °C for 12 h to remove CTAC. To ensure the complete removal of CTAC, thi...

Embodiment 3

[0042] Embodiment 3: Magnetic mesoporous nanoparticle Fe 3 o 4 @SiO 2 @mSiO 2 - Preparation of EDPS

[0043] Will Fe 3 o 4 Disperse 80 mg of magnetic nanoparticles in a mixture of 160 mL of ethanol and 40 mL of water by ultrasonication for 40 minutes, and add 3 mL of NH 3 ·H 2 O, then add 4mL TEOS dropwise within 10min, continue to stir at 35°C for 6h, wash with ethanol and deionized water three times, magnetically separate, and vacuum dry at 40°C for 10h to obtain SiO 2 Coated Fe with uniform size and core-shell structure 3 o 4 @SiO 2 magnetic microspheres.

[0044] Take 80mg Fe 3 o 4 @SiO 2 The magnetic microspheres were dispersed in a mixed solution containing 95mL water, 43mL ethanol, 4mL ammonia water and 0.3g CTAC by ultrasonication for 30min. Subsequently, 2 mL of TEOS was mixed in 7.5 mL of ethanol and added dropwise to the reaction system with stirring. After 15 minutes of reaction, the particles were formed, and 2.5mL EDPS was added dropwise to the sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com