Method for preparing porous magnetic imprinting adsorbent by emulsion polymerization

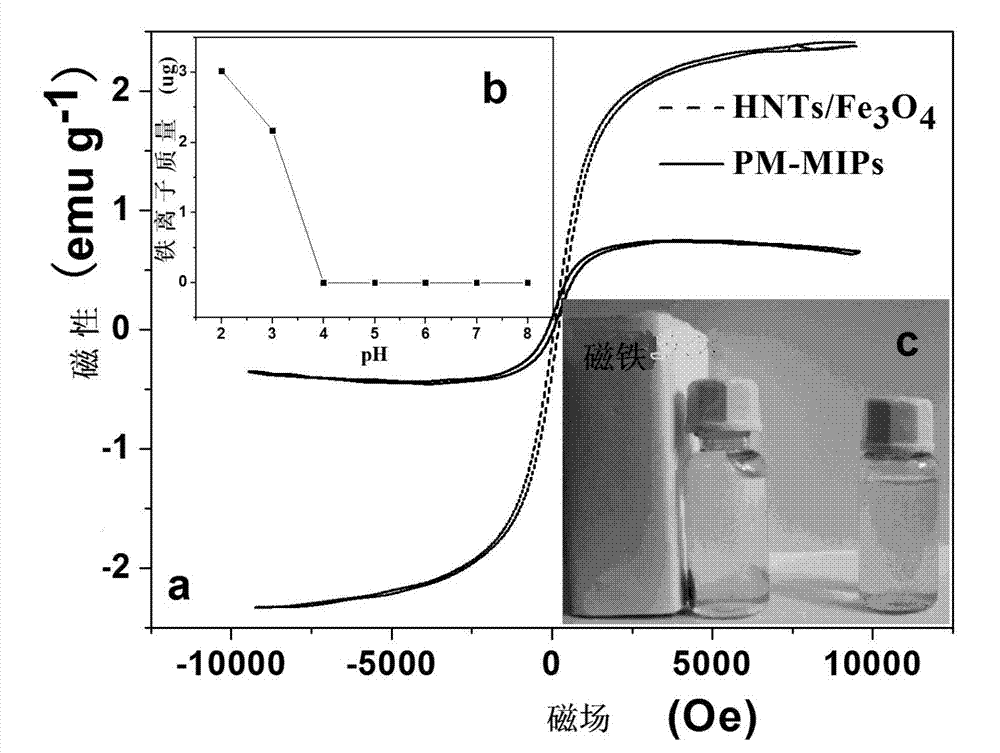

An emulsion polymerization, imprinted adsorption technology, applied in selective adsorption, chemical instruments and methods, alkali metal compounds, etc., can solve problems such as damage to the central nervous system, endocrine disruption, adverse health effects, etc., to achieve high adsorption capacity, rapid separation and The effect of identifying with temperature and good magnetic response properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

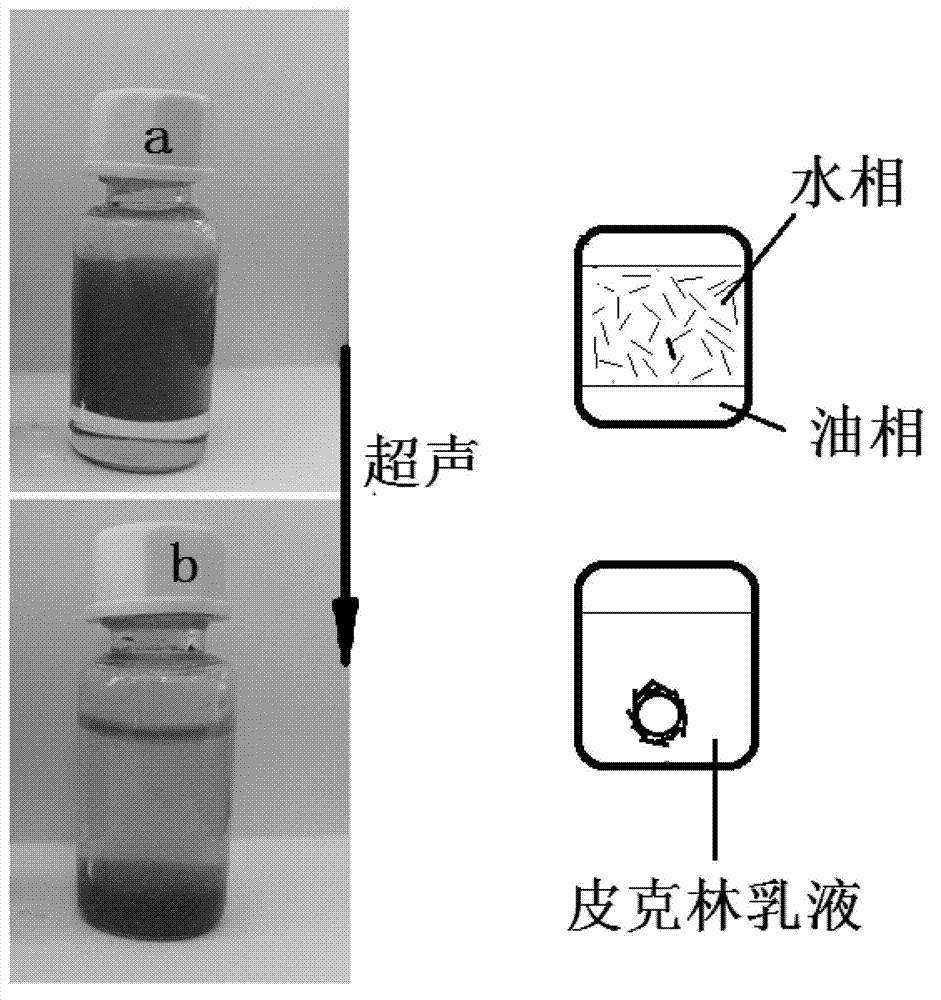

[0039] 1. A method for preparing porous magnetic imprinted adsorbent by Pickering emulsion polymerization

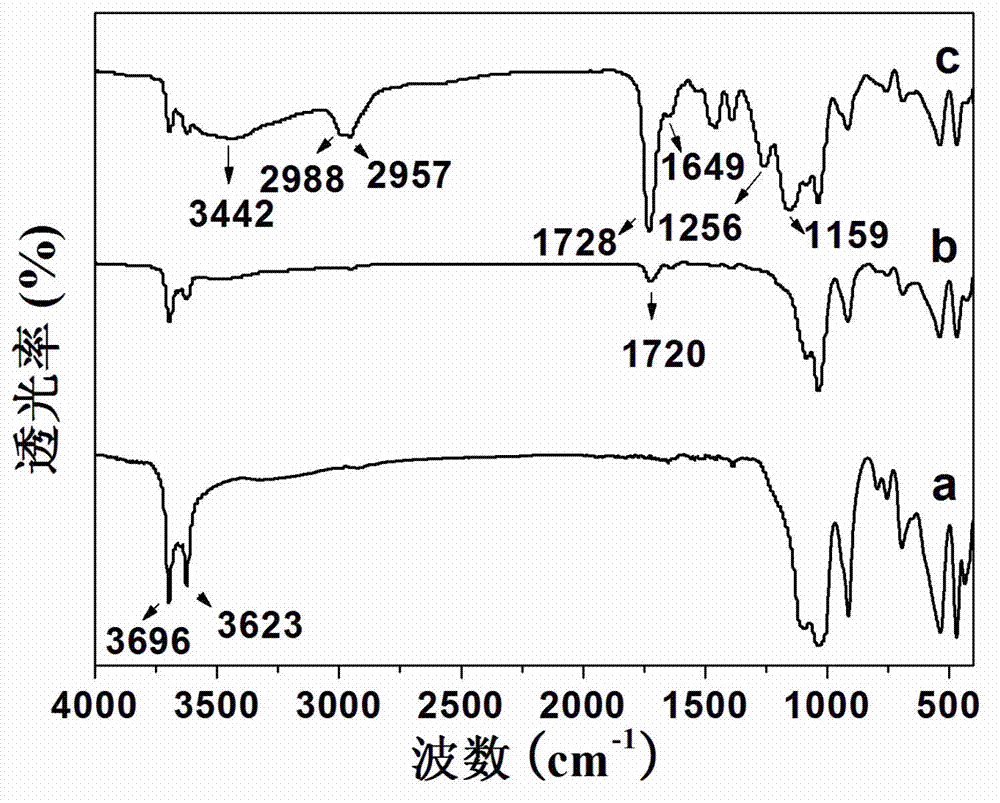

[0040] (1) Activation of halloysite nanotubes (HNTs)

[0041] The massive halloysite nanotubes are ground and crushed through 100 sieves, and the halloysite nanotubes are 70% in 3.0mol / L nitric acid o C reflux for 10 hours. Wash with distilled water until neutral, and dry in vacuum. at 200 oC Calcined at high temperature for 2 hours, subsequently, at 50 o Dry at C for later use.

[0042] (2) Magnetic halloysite nanotubes (HNTs / Fe 3 o 4 ) synthesis and vinyl modification

[0043] 0.05g Fe(NO 3 )×9H 2 O and 0.10 g of activated halloysite nanotubes were added to 10 ml of ethanol. Dry naturally after ultrasonic dispersion. Soak in propionic acid vapor at 80°C for 15 hours. The mixture was then calcined at 265°C for 2 hours under nitrogen protection. After cooling to room temperature, the prepared magnetic halloysite nanotubes were washed with diluted hydrochlor...

Embodiment 2

[0062] 1. A method for preparing porous magnetic imprinted adsorbent by Pickering emulsion polymerization

[0063] (1) Activation of halloysite nanotubes (HNTs)

[0064] The massive halloysite nanotubes are ground and crushed through 100 sieves, and the halloysite nanotubes are 70% in 3.5mol / L nitric acid o C reflux for 8 hours. Wash with distilled water until neutral, and dry in vacuum. at 200 oC Calcined at high temperature for 2 hours, subsequently, at 60 o Dry at C for later use.

[0065] (2) Magnetic halloysite nanotubes (HNTs / Fe 3 o 4 ) synthesis and vinyl modification

[0066] 0.05g Fe(NO 3 )×9H 2 O and 0.05 g of activated halloysite nanotubes were added to 5 ml of ethanol. Ultrasonic dispersion, dry naturally. Soak in propionic acid vapor at 80°C for 12 hours. The mixture was then calcined at 265°C for 2 hours under nitrogen protection. After cooling to room temperature, the prepared magnetic halloysite nanotubes were washed with diluted hydrochloric acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com