Thermal insulation material with anti-corrosion effect

A thermal insulation material and anti-corrosion technology, which is applied in the direction of manufacturing tools, glass manufacturing equipment, glass fiber drawing devices, etc., can solve the problems of enhanced thermal insulation coefficient, easy moisture absorption, unstable properties, etc., to improve anti-corrosion performance, Improve overall performance and solve the effect of quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

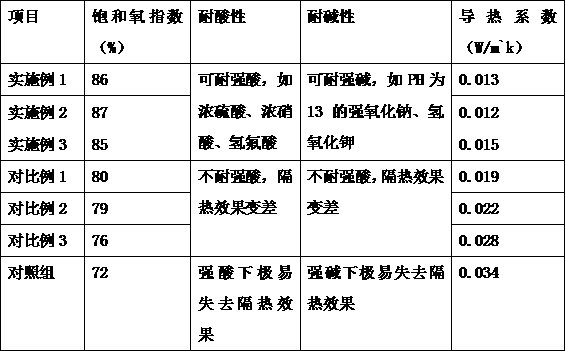

Examples

Embodiment 1

[0019] A heat insulating material with anti-corrosion effect, made of the following components in parts by weight: 40 parts of quartz fiber, 20 parts of potassium hexatitanate whisker, 14 parts of starch solution, 12 parts of airgel silicon dioxide, silicone oil 10 parts, 10 parts of amide, 4 parts of polyaluminum chloride, 1.0 part of glass powder, 0.8 part of titanium dioxide, 14 parts of water, and its preparation method comprises the following steps:

[0020] (1) Separate the agglomerated quartz fibers into small groups, the diameter of the small groups is between 2-4 mm, add water to stir after separation, the stirring speed is 300 rpm, the stirring time is 40 minutes, and use a 40-mesh sieve after stirring Carry out washing, filter and remove the slag, and the above steps are repeatedly processed 3 times to obtain smooth and dispersed quartz fibers;

[0021] (2) Airgel silica was calcined at 850°C for 3 hours to obtain nano-silicon oxide, which was mechanically stirred a...

Embodiment 2

[0030] A heat insulating material with anti-corrosion effect, made of the following components in parts by weight: 42 parts of quartz fiber, 22 parts of potassium hexatitanate whisker, 16 parts of starch solution, 13 parts of airgel silicon dioxide, silicone oil 12 parts, 11 parts of amide, 5 parts of polyaluminium chloride, 1.2 parts of glass powder, 0.9 part of titanium dioxide, 15 parts of water, and its preparation method comprises the following steps:

[0031] (1) Separate the agglomerated quartz fibers into small groups, the diameter of the small groups is between 2-4 mm, add water to stir after separation, the stirring speed is 350 rpm, the stirring time is 35 minutes, and use a 50-mesh sieve after stirring Carry out washing, filter and remove the slag, and the above steps are repeatedly processed 4 times to obtain smooth and dispersed quartz fibers;

[0032] (2) Airgel silica was calcined at 880°C for 2.5 hours to obtain nano-silicon oxide, which was mechanically stirr...

Embodiment 3

[0041] A heat insulating material with anti-corrosion effect, made of the following components in parts by weight: 45 parts of quartz fiber, 25 parts of potassium hexatitanate whisker, 18 parts of starch solution, 15 parts of airgel silicon dioxide, silicone oil 15 parts, 12 parts of amide, 6 parts of polyaluminum chloride, 1.5 parts of glass powder, 1.0 part of titanium dioxide, 20 parts of water, and its preparation method comprises the following steps:

[0042] (1) Separate the agglomerated quartz fibers into small groups, the diameter of the small groups is between 2-4 mm, add water to stir after separation, the stirring speed is 400 rpm, the stirring time is 30 minutes, and use a 60-mesh sieve after stirring Carry out washing, filter and remove the slag balls, and the above steps are repeatedly processed 5 times to obtain smooth and dispersed quartz fibers;

[0043] (2) Airgel silica was calcined at 900°C for 2 hours to obtain nano-silicon oxide, which was mechanically st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com