Hemodialysis equipment

A technology of hemodialysis and equipment, applied in dialysis systems, catheters, suction devices, etc., can solve the problems of large dialysis equipment, death, and difficulty in transportation, and achieve the effect of increasing dialysis area and improving dialysis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

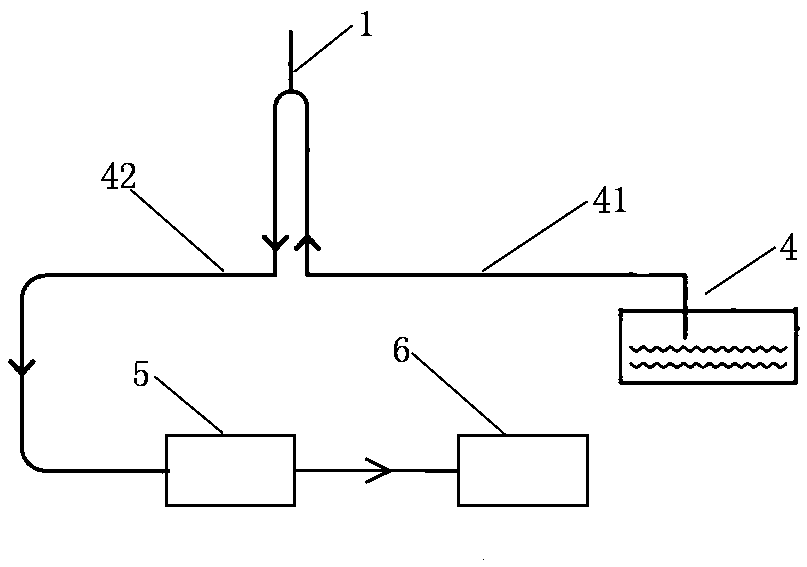

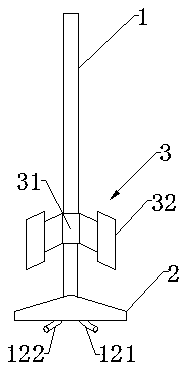

[0040] Such as Figure 1-4 As shown, this embodiment provides a hemodialysis device, which includes a dialysis tube 1, a connection part 2 connected to the dialysis tube 1, a fixing part 3 provided between the dialysis tube 1 and the connection part 2, a dialysate container 4, Peristaltic pump 5 and waste liquid tank 6. The dialysate container 4 is connected to the connection part through a liquid inlet tube 41, the peristaltic pump 5 is connected to the connection part through a liquid outlet tube, and the waste liquid cylinder 6 is connected to the peristaltic pump 5 through a tube.

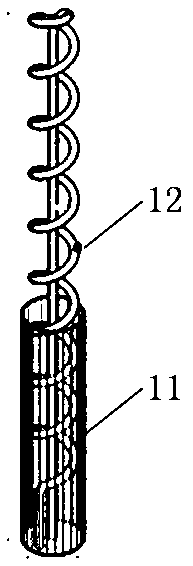

[0041] The dialysis tube 1 includes a dialysis outer tube 11, a dialysis inner tube 12, and a dialysis membrane. The outer dialysis tube 11 is sleeved on the periphery of the inner dialysis tube 12. There is a gap between the outer dialysis tube 11 and the inner dialysis tube 12 to facilitate blood circulation. The outer dialysis tube 11 is hollowed out to facilitate blood entering the outer dial...

Embodiment 2

[0049] This embodiment provides a polytetrafluoroethylene-polyurethane-nano-silver composite material and a preparation method thereof. The polytetrafluoroethylene-polyurethane-nano-silver composite material has good biocompatibility and antibacterial properties, and is used for hemodialysis The built-in dialysis tube has good application prospects. The polytetrafluoroethylene-polyurethane-nano silver composite material is prepared through the following steps:

[0050] Step 1: Weigh 54g of concentrated polytetrafluoroethylene dispersion, 38g of diisocyanate, 14g of polycaprolactone diol, stir and mix and heat to 80°C, add 0.08g of 1,4-butanediol and stannous octoate to it 0.06g, continue to stir and maintain the heating temperature to react for 3h, then increase the temperature to 90℃, and add 0.13g trimethylolpropane monoallyl ether and continue to react for 3h to obtain the polytetrafluoroethylene-polyurethane composite material;

[0051] Step 2: Disperse the polytetrafluoroethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com