Spider dragline silk protein and biosynthesis method thereof

A spider silk protein and biosynthesis technology, applied in the biological material and biological field, can solve the problems such as fusion of spider silk protein and collagen which has not yet been seen, and achieve the effects of being beneficial to separation and purification, reducing production costs and facilitating cultivation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

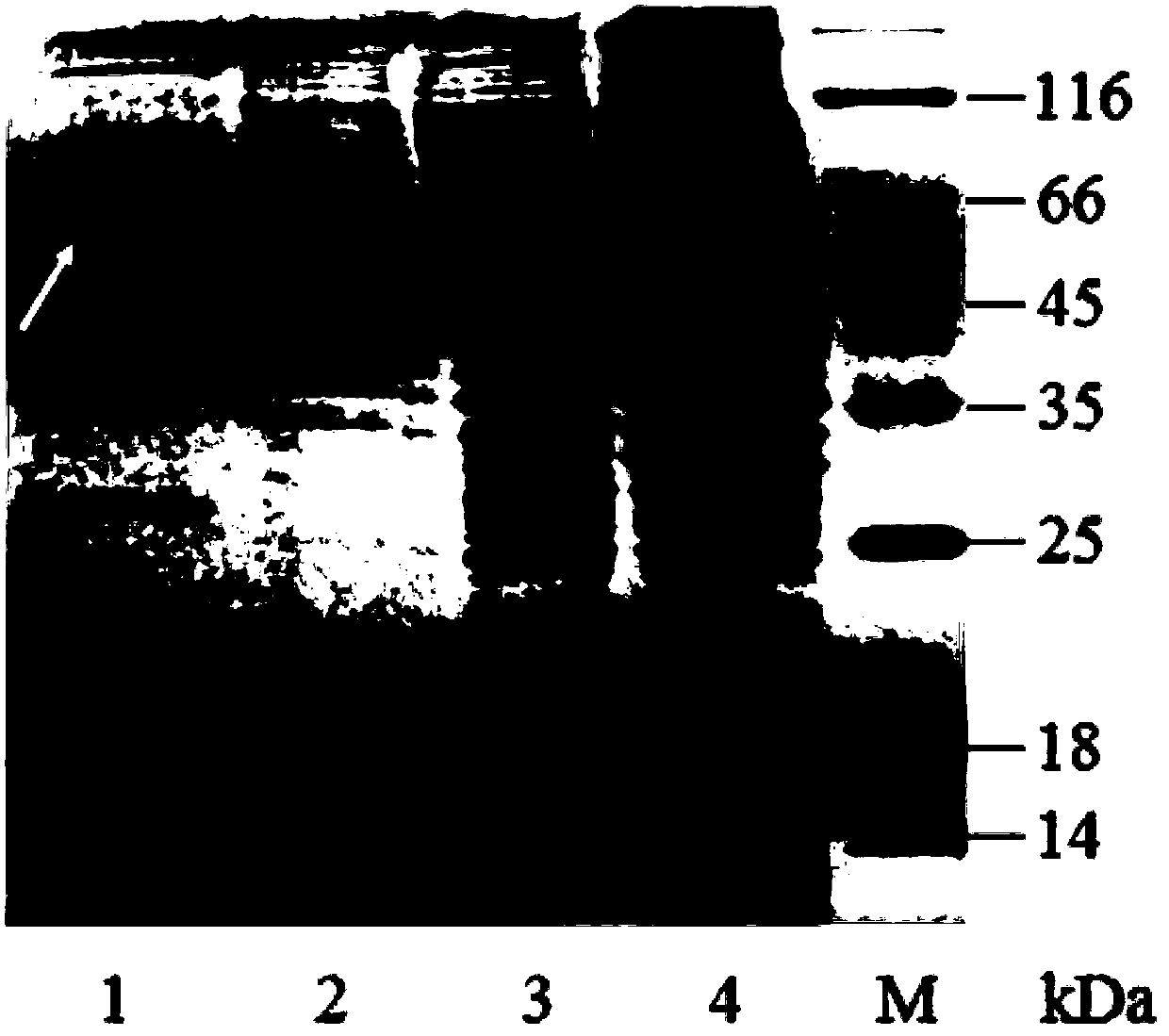

[0046] Example 1: Construction, expression and product purification of spidroin gene:

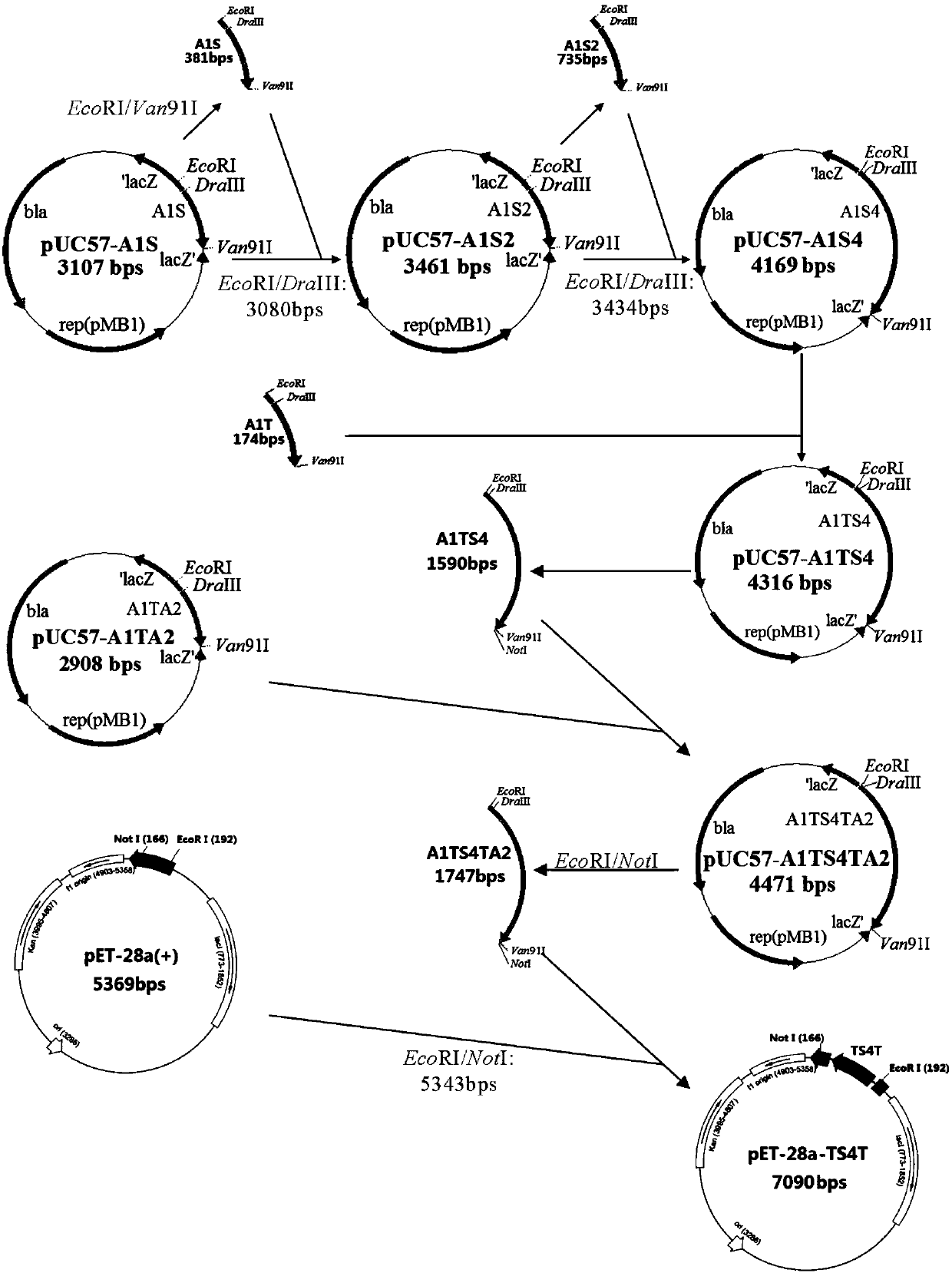

[0047] According to GenBank's spider silk protein gene sequences AY555585 and AH015065, the structural characteristics of the spidroin gene sequence and the degeneracy of codons, the corresponding DNA sequence was modified on the original basis, and the spidroin gene monomer S was designed. And use the Garnier method of Antheprot software to predict the secondary structure of the protein. Add recognition sites for isotail enzymes DraIII and Van91I at both ends of the gene monomer S; design adapters A1 (A1-1, A1-2) and A2 (A2-1, A2-2) a total of four single-stranded DNA fragments, A1 -1 and A1-2 contain the recognition site of EcoRI, and A2-1 and A2-2 contain the recognition site of NotI. Design (Pro-Gly-Pro) n Collagen-like protein homopolymer extension gene, the trimer repeat number n is determined to be 15, and the recognition sites of homologous enzymes DraIII and Van91I are added at b...

Embodiment 2

[0067] Example 2: Structural characterization analysis of spidroin-like proteins

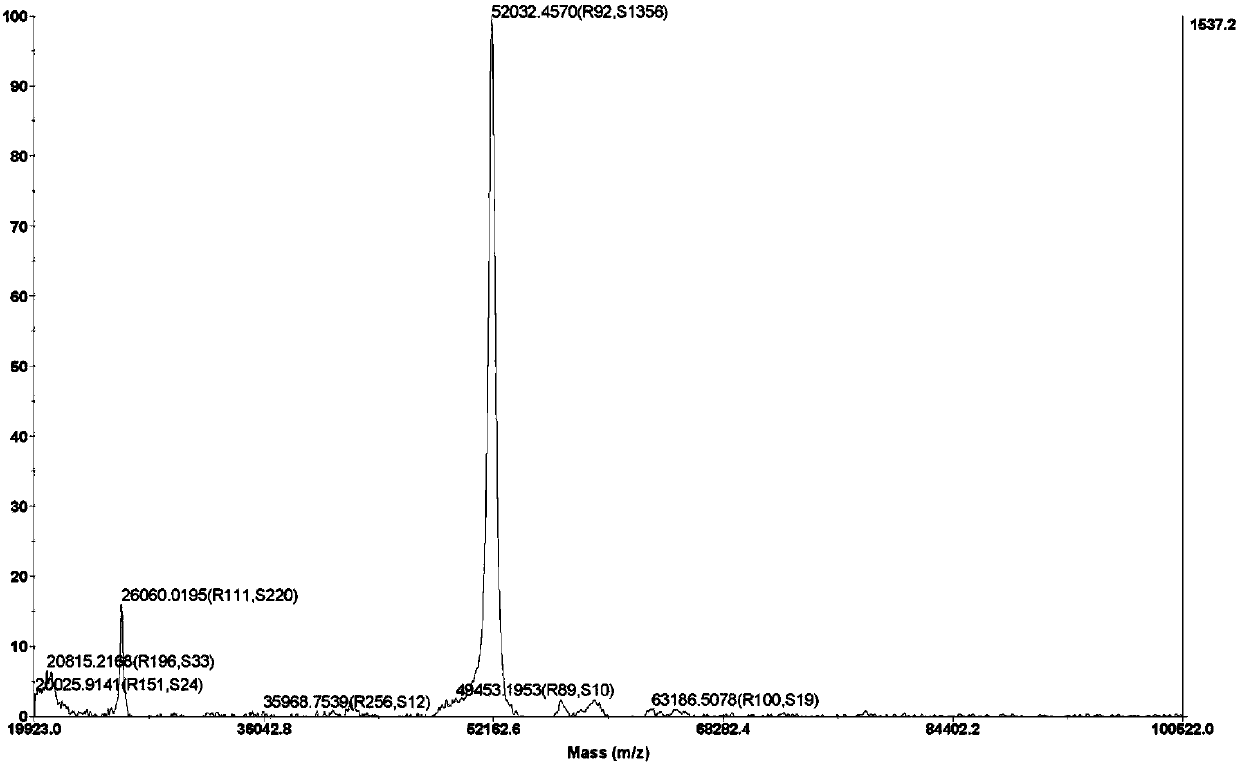

[0068] Mass spectrometry analysis was performed on the isolated and purified spidroin, and the results were as follows: image 3 As shown, the results of mass spectrometry analysis show that the molecular weight of the pseudospiderin is 52032.46Da; the theoretically designed pseudospiderin contains 615 amino acids, and the molecular weight is 52242.93Da; the exact molecular weight of the actual pseudospiderin and the designed pseudospider The theoretical molecular weight of the protein is similar.

[0069] Infrared spectroscopic analysis was carried out on the isolated and purified spidroin, and the results were as follows: Figure 4 As shown, from the wave numbers of amide A, amide B, amide I, amide II, and amide III in the infrared spectrum analysis, it can be judged that the pseudo-spider silk protein has similar structural features to the natural spidroin protein.

[0070] The circular dic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com