Active carbon material with spherical structure and preparation method and applications thereof

A kind of activated carbon and spherical technology, which is applied in the field of activated carbon materials and its preparation, can solve the problems of uneven discharge capacity and cycle efficiency of lithium-sulfur batteries, difficulty in ensuring the high quality of lithium-sulfur batteries, and no activated carbon materials have been found yet. Effects of chemical properties, good application prospects, excellent morphology and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

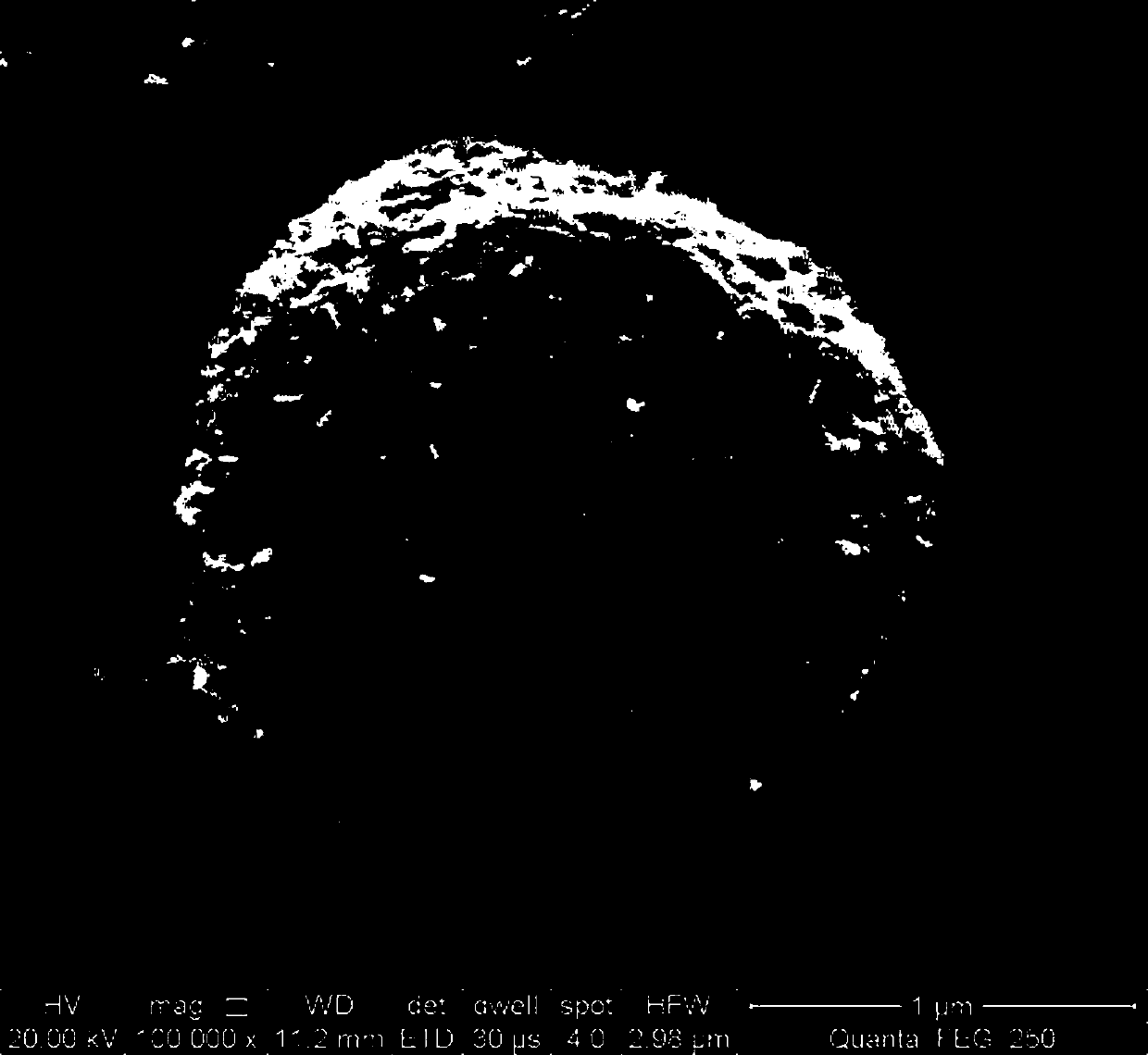

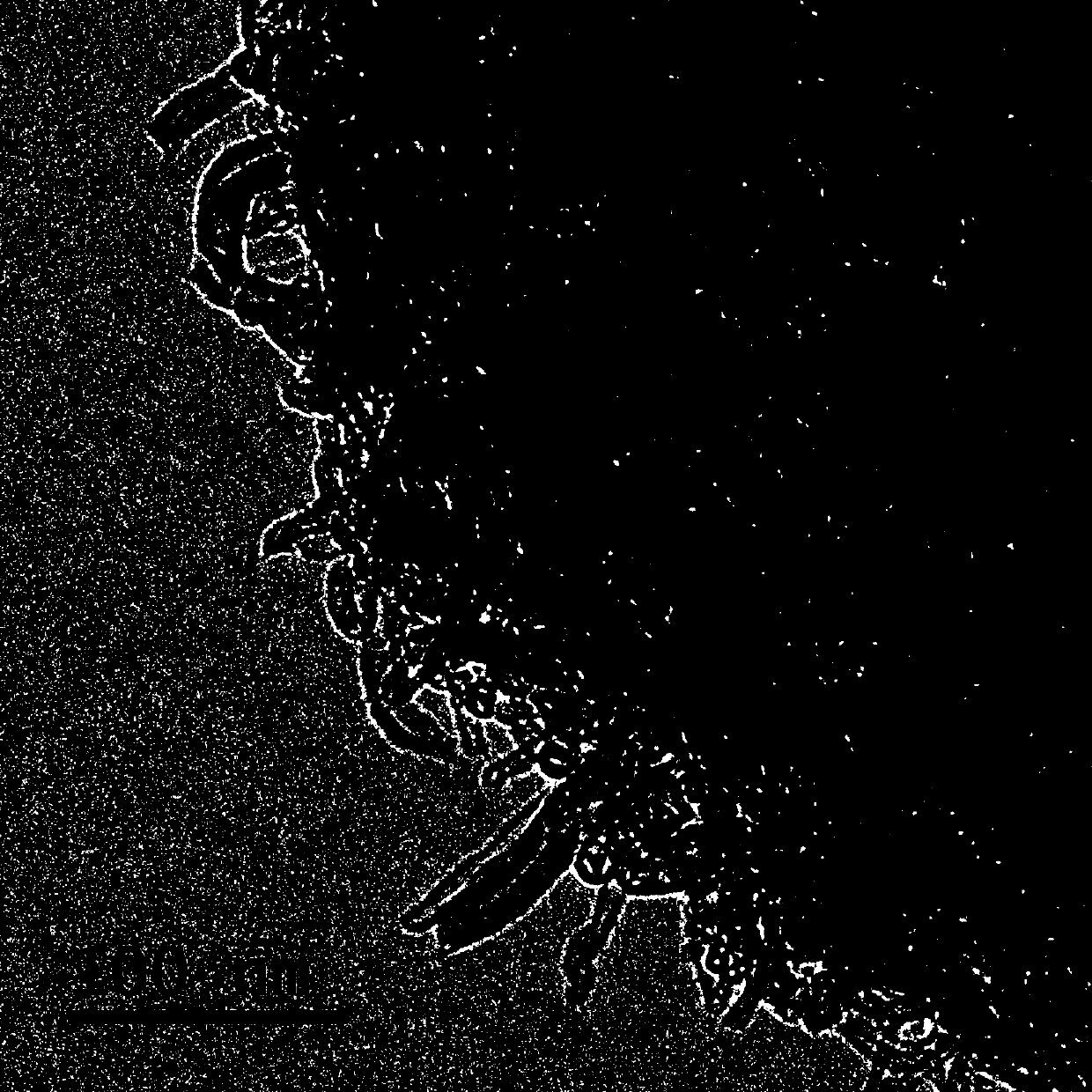

[0038] There is the preparation method of the activated carbon material of spherical structure, comprises the steps:

[0039] S1. Ultrasonic dispersion: Mix carbohydrates and carbon materials in a deionized aqueous solution at room temperature for 3 to 24 hours, then use an electromagnetic ultrasonic device for ultrasonic dispersion. The power of ultrasonic dispersion is 200 to 750W; the time of ultrasonic dispersion is 0.5 ~10h, to obtain a mixed solution;

[0040] S2. Spray pyrolysis treatment: the mixed solution described in step S1 is placed in a two-necked flask, and after being atomized by an ultrasonic nebulizer, the atomized mixed solution is passed into a vacuum tube furnace with an inert gas in advance to carry out Constant temperature treatment, pre-heating to 350-450°C, after 24 hours; constant temperature until the end of spraying and then continuing for 2 hours, after the reaction furnace is cooled to room temperature, collect the deposited product in the tube; ...

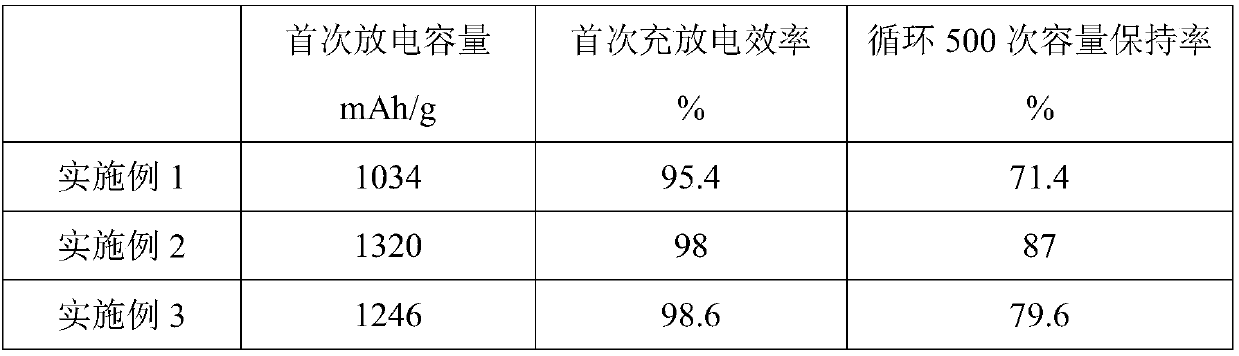

Embodiment 1

[0044] (1) Preparation method of activated carbon material with spherical structure

[0045] There is the preparation method of the activated carbon material of spherical structure, comprises the steps:

[0046] S1. Ultrasonic dispersion: Mix sucrose and graphite in a mass ratio of 4:1 and place them in a deionized aqueous solution, wherein the mass ratio of the total mass of sugars and carbon materials to deionized water is 1:40. At room temperature, use Electromagnetic stirrer, after mixing and stirring for 3 hours, use an electromagnetic ultrasonic device to perform ultrasonic dispersion at a power of 200W; the time of ultrasonic dispersion is 1 hour to obtain a mixed solution;

[0047] S2. Spray pyrolysis treatment: the mixed solution in step S1 is placed in a double-necked flask fixed on an ultrasonic spray device, atomized by an ultrasonic sprayer with a flow rate of 200-300cc / min, and the atomized mixed solution is passed through the pre- In the electromagnetic vacuum ...

Embodiment 2

[0053] (1) Preparation method of activated carbon material with spherical structure

[0054] There is the preparation method of the activated carbon material of spherical structure, comprises the steps:

[0055] S1. Ultrasonic dispersion: Mix sucrose and carbon nanotubes at a mass ratio of 5:1 and place them in a deionized aqueous solution, use an electromagnetic stirrer at room temperature, mix and stir for 6 hours, and use an electromagnetic ultrasonic device at a power of 750W to carry out Ultrasonic dispersion; the time of ultrasonic dispersion is 0.5h, and a mixed solution is obtained;

[0056] S2. Spray pyrolysis treatment: the mixed solution in step S1 is placed in a two-necked flask fixed on an ultrasonic spray device, atomized by an ultrasonic sprayer with a flow rate of 200-300cc / min, and the atomized mixed solution is passed through a pre-pass In an electromagnetic vacuum tube furnace with argon gas, heat up to 400°C at a heating rate of 5°C / min for constant temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com