High-strength glass colored glaze

A high-strength, high-strength glass technology, applied in blown glass, glass forming, glass manufacturing equipment, etc., can solve problems such as fragmentation and low strength of glass glaze, achieve the effect of reducing glass phase and pores and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

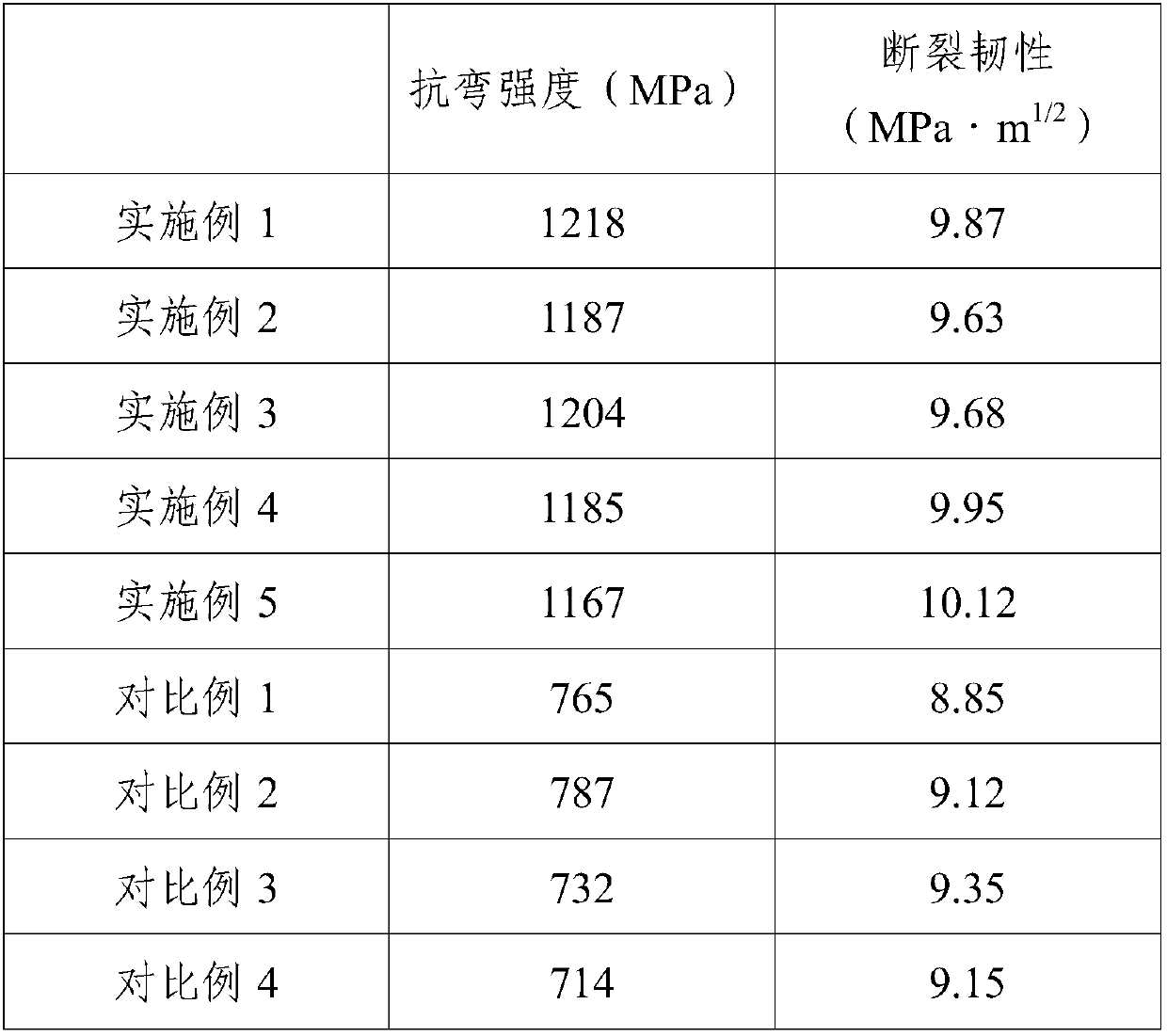

Examples

Embodiment 1

[0014] The preparation steps of the glass glaze of the present embodiment are as follows:

[0015] 1) Weigh each raw material: 70 parts of quartz sand, 25 parts of soda ash, nano-α-Al 2 o 3 25 parts, 4 parts of cerium oxide, 0.6 parts of sodium nitrate, 3 parts of barium carbonate, 28 parts of cordierite powder, 10 parts of zirconium silicate, 10 parts of potassium feldspar, 8 parts of lithium china stone, 1 part of CuO, mix well;

[0016] 2) The raw materials are melted in a pool kiln, the melting temperature is 1540°C, the clarification temperature is 1660°C, the melting time is 10 hours, and the clarification time is 5 hours to obtain a glass melt;

[0017] 3) Cool the melted glass melt to 1100°C, and carry out artificial forming according to the designed shape. The artificial forming specifically includes: manual material picking, through tools such as scissors, handles, blowpipes, molds, etc., through manual blowing, pulling, pressing, Turning, squeezing and other proc...

Embodiment 2

[0020] The preparation steps of the glass glaze of the present embodiment are as follows:

[0021] 1) Weigh each raw material: 72 parts of quartz sand, 22 parts of soda ash, nano-α-Al 2 o 3 28 parts, 2 parts of cerium oxide, 0.5 parts of sodium nitrate, 2 parts of barium carbonate, 30 parts of cordierite powder, 8 parts of zirconium silicate, 6 parts of potassium feldspar, 5 parts of lithium china stone, 0.6 part of FeO, mix well;

[0022] 2) Melting the raw materials in a tank kiln, the melting temperature is 1520°C, the clarification temperature is 1650°C, the melting time is 12 hours, and the clarification time is 5 hours to obtain a glass melt;

[0023] 3) Cool the melted glass melt to 1100°C, and carry out artificial forming according to the designed shape. The artificial forming specifically includes: manual material picking, through tools such as scissors, handles, blowpipes, molds, etc., through manual blowing, pulling, pressing, Turning, squeezing and other process...

Embodiment 3

[0026] The preparation steps of the glass glaze of the present embodiment are as follows:

[0027] 1) Weigh each raw material: 65 parts of quartz sand, 20 parts of soda ash, nanometer α-Al 2 o 3 24 parts, 3 parts of cerium oxide, 0.5 parts of sodium nitrate, 2.5 parts of barium carbonate, 25 parts of cordierite powder, 9 parts of zirconium silicate, 12 parts of potassium feldspar, 6 parts of lithium china stone, TiO 2 0.5 parts, mix well;

[0028] 2) Melting the raw materials in a pool kiln, the melting temperature is 1550°C, the clarification temperature is 1680°C, the melting time is 10 hours, and the clarification time is 4.5 hours to obtain a glass melt;

[0029] 3) Cool the melted glass melt to 1100°C, and carry out artificial forming according to the designed shape. The artificial forming specifically includes: manual material picking, through tools such as scissors, handles, blowpipes, molds, etc., through manual blowing, pulling, pressing, Turning, squeezing and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com