A kind of coal-based polymer hydrogel and preparation method thereof

A composite hydrogel and hydrogel technology, which is applied in the field of polymer materials, can solve problems such as environmental pollution, gaps in flexibility and mechanical strength, and weak bonding, and achieve improved environmental friendliness, high environmental friendliness, and stimulation of crops. The effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

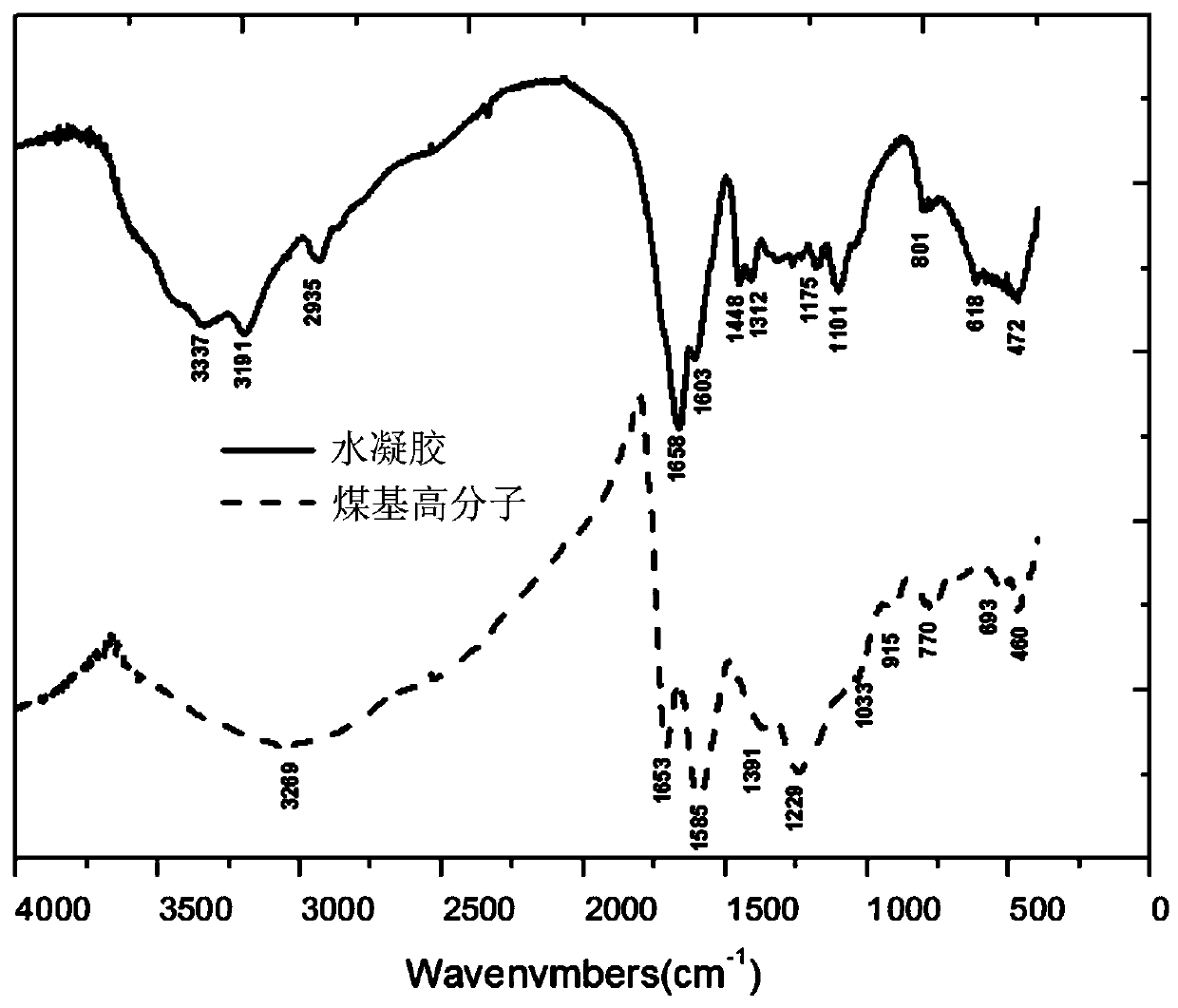

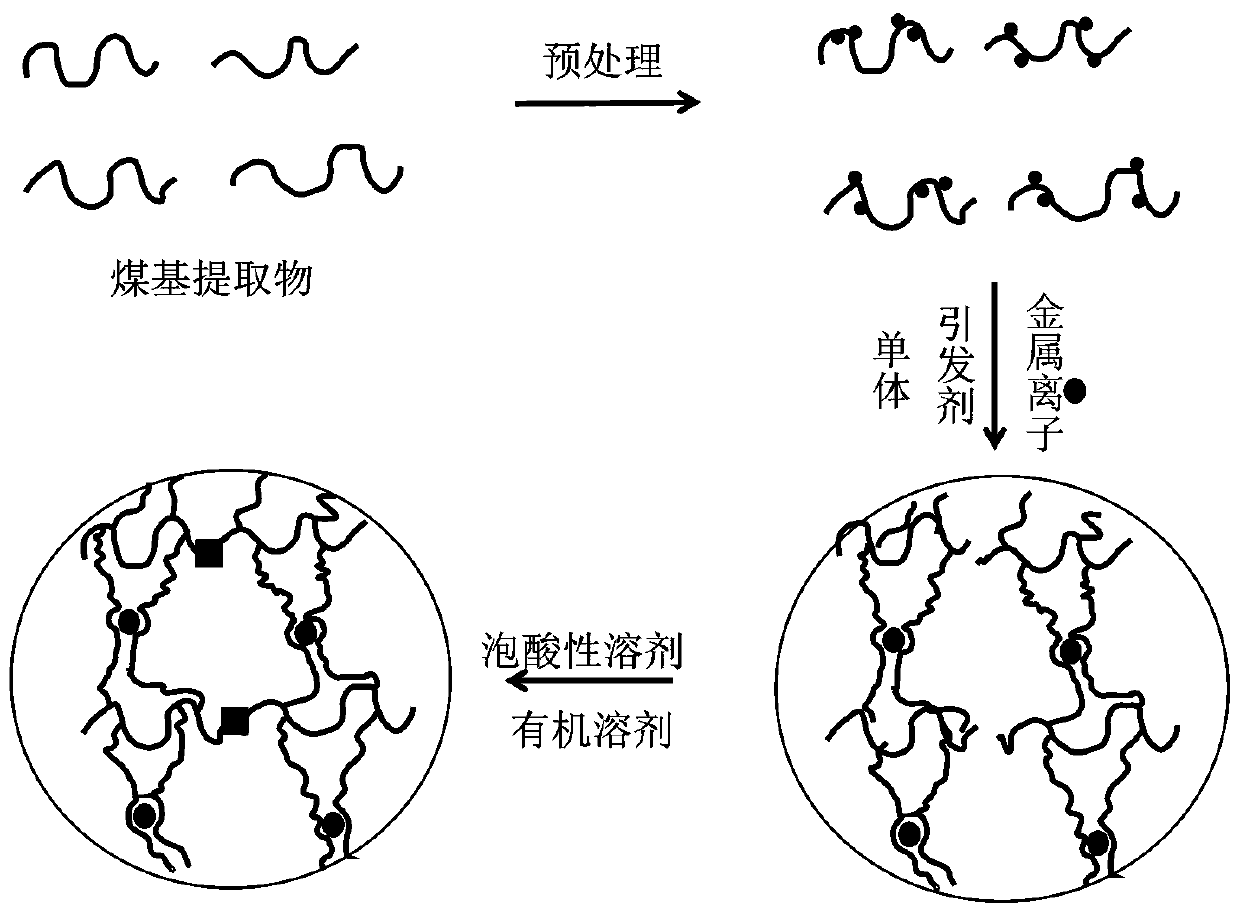

[0044] Weigh 100 g of low calorific value coal, put it in a 2500 ml beaker, add 1800 mL of 1.0 mol / L NaOH aqueous solution, and stir at room temperature for 36 h. The insoluble matter was removed by filtration, and then 6 mol / L HCl aqueous solution was slowly added dropwise to the filtrate until the pH was 3, filtered, the black solid was collected and placed in a drying oven, and dried at 105 °C to constant weight to obtain a coal-based polymer.

[0045] Dissolve 10.0 g of coal-based polymer in 19.0 g of deionized water, and add 1.0 mol / L NaOH solution to adjust the pH of the solution to 8-10. Add 1.0 g hydrogen peroxide and pre-react at 45°C for 2 h to obtain solution I.

[0046] 0.54 g of acrylic acid, 0.67 g of ferric chloride hexahydrate, 2.13 g of acrylamide and 0.12 g of potassium persulfate were sequentially added to 10.0 g of deionized water to obtain solution II. To solution II, add 1.5 g of solution I and mix. The mixture was stirred in an ice-water bath for 30 mi...

Embodiment 2

[0054] On the basis of Example 1, take 10.0 g of the coal-based polymer obtained in Example 1, dissolve it in 19.0 g of deionized water, add 1.0 mol / L NaOH solution to adjust the pH value of the solution to 8-10, add 1.0 g of hydrogen peroxide , and reacted at 55°C for 2 h to obtain solution Ⅰ.

[0055] Add 3.8 g of acrylamide and 0.085 g of potassium persulfate to 9.8 g of water to obtain solution II. To solution II, add 2.0 g of solution I and mix. The mixture was stirred in an ice-water bath for 30 min, and deoxygenated with nitrogen for 10 min. The mixture is then transferred into glass molds and sealed. Place in an oven at 50°C for 5 h. demoulding. The formed coal-based polymer-acrylamide composite hydrogel was soaked in a pH=3 ethanol-water mixed solution (made by mixing 1.5 mL of ethanol and 20 mL of water) for 20 h. The resulting coal-based polymer hydrogel has a tensile strength of 1.2 MPa and an elongation at break of 290%. When acrylic acid is 0, Fe 3+ When t...

Embodiment 3

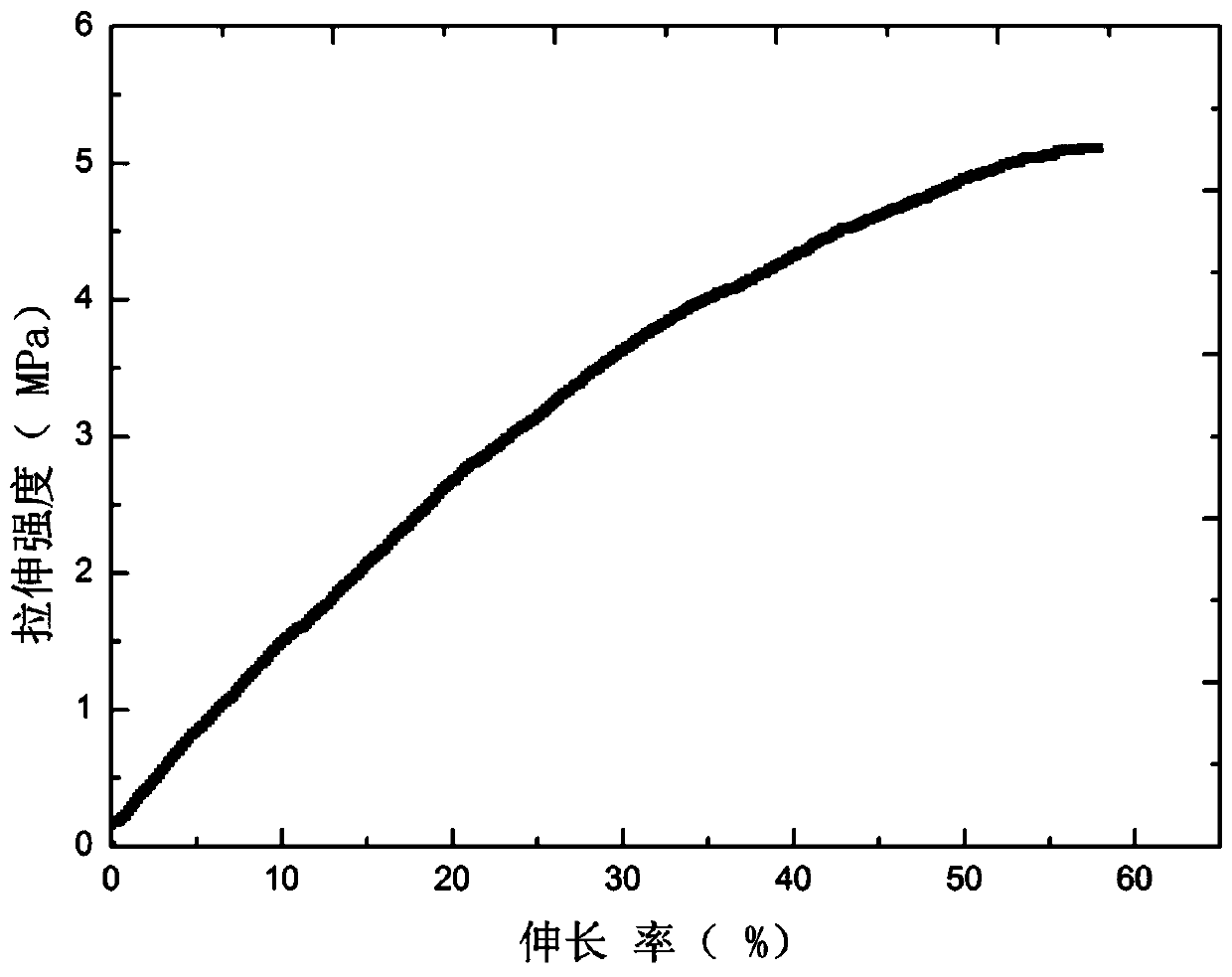

[0058] On the basis of Example 1, 0.27 g of acrylic acid, 0.32 g of ferric chloride hexahydrate, 1.96 g of acrylamide and 0.17 g of potassium persulfate were added to 9.8 g of water to obtain solution II. To solution II, add 2.0 g of solution I obtained in Example 1, and mix. The mixture was stirred in an ice-water bath for 30 min, and deoxygenated with nitrogen for 10 min. The mixture is then transferred into glass molds and sealed. Place in an oven at 55°C for 5 h. demoulding. Soak the formed coal-based polymer-acrylamide composite hydrogel in an acetone-water mixed solution (made by mixing 0.5 mL of acetone and 20 mL of water) at pH=3 for 12 h. The resulting coal-based polymer hydrogel has a tensile strength of 4.5 MPa and an elongation at break of 120%.

[0059] For the tensile curve of the coal-based polymer hydrogel obtained in Example 3 of the present invention, see Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com