FRP spiral bar enhanced stainless steel tube seawater and seasand concrete structure

A technology for concrete structures and stainless steel pipes, applied in columns, piers, pillars, etc., can solve the problems of reduced structural bearing capacity and ductility, lack of corrosion resistance, and lack of fresh water resources, avoiding stress concentration and high bearing capacity. , good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

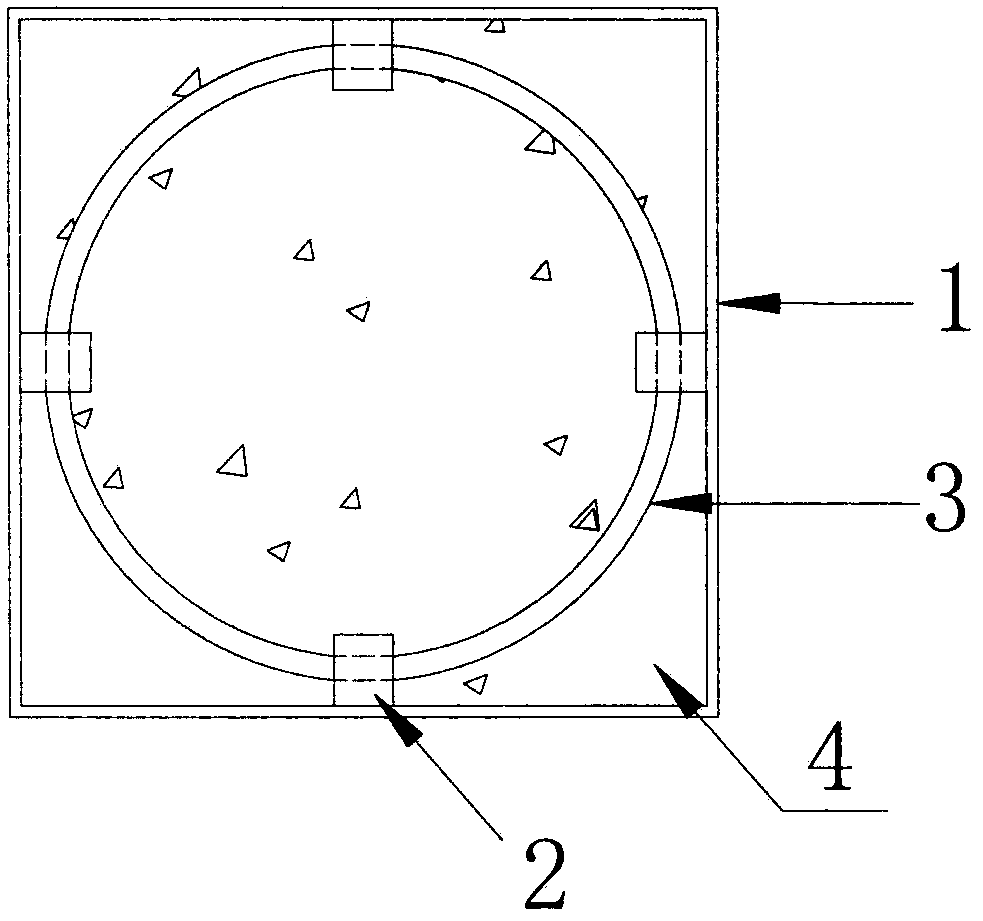

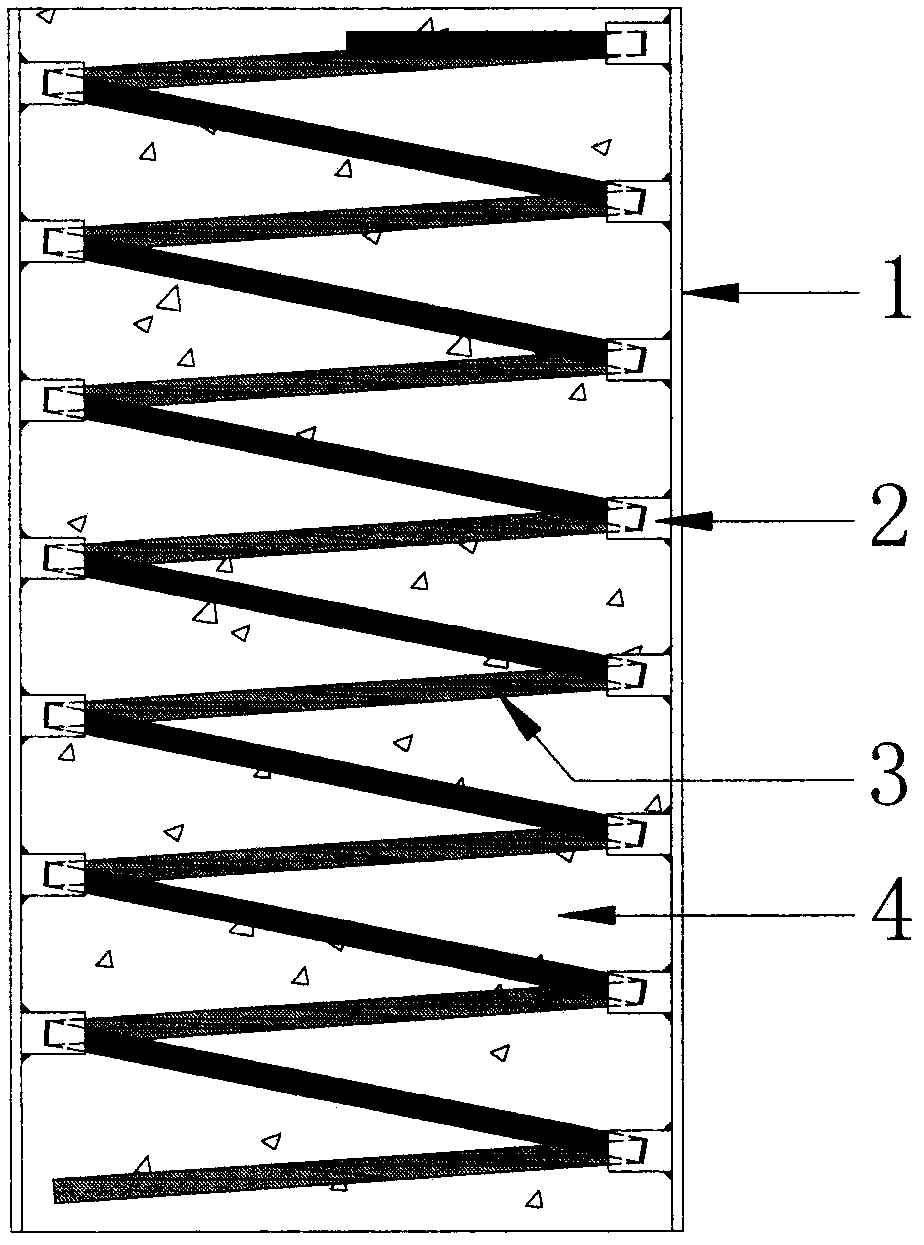

[0030] In the specific implementation, the rectangular stainless steel pipe 1 is first processed according to the predetermined cross-sectional shape and size, and can be formed by cold bending welding process. The material of the FRP spiral rib 3 can be one or more of glass fiber, carbon fiber, aramid fiber, and basalt fiber. According to the designed spiral pitch and spiral diameter, the FRP spiral rib 3 is processed, and then the anchor piece 2 is processed. The anchor piece 2 is a stainless steel block with a reserved hole. Rotate the FRP spiral bars 3 through a predetermined number of anchors 2, and then weld the anchors 2 to the inner walls around the rectangular stainless steel pipe 1. The spacing between the anchors 2 is consistent with the helical pitch of the FRP spiral bars 3. The material and seawater are configured with seawater sea-sand concrete 4, and the seawater sea-sand concrete 4 is poured into the rectangular stainless steel pipe 1, and at the same time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com