Solar cell back membrane and preparation method thereof

A solar cell and back film technology, which is applied in the field of solar cells, can solve the problems of high preparation costs, achieve the effects of increasing surface tension, improving adhesion, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

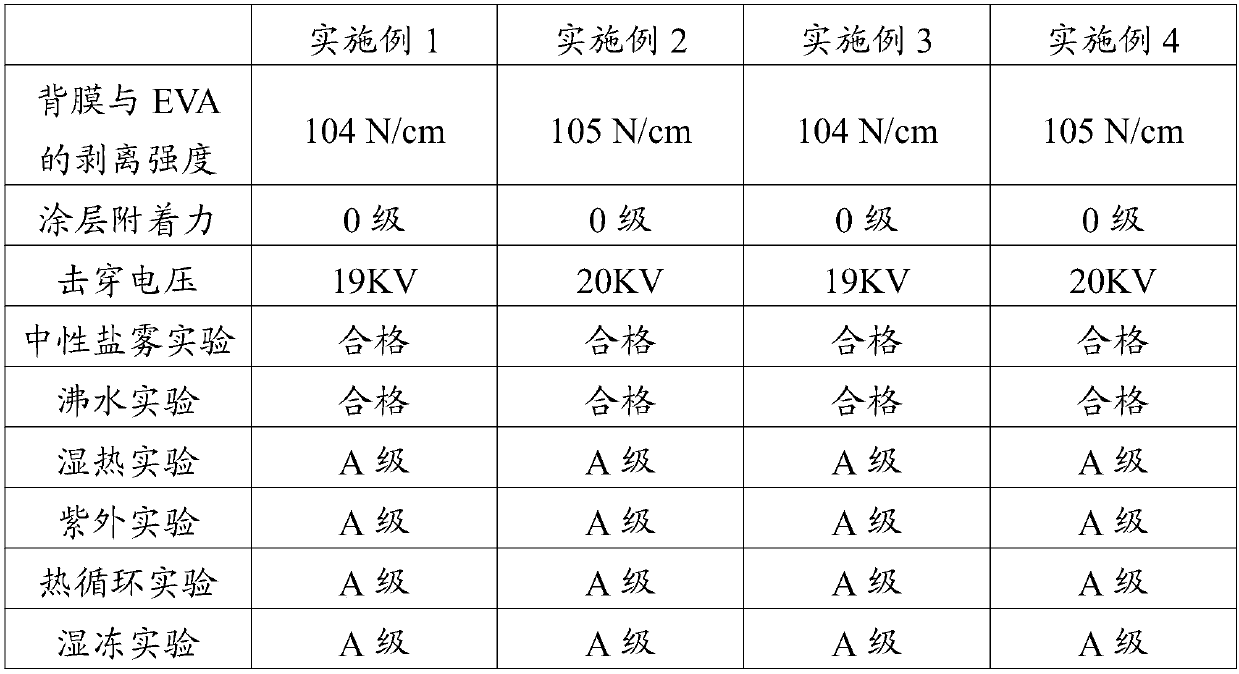

Examples

preparation example Construction

[0018] The invention provides a preparation method of a solar cell back film, which comprises the following steps of performing corona, dip coating and heat treatment on a base film in sequence to obtain a solar cell back film.

[0019] In the present invention, the base film preferably includes a PET base film. The present invention has no special requirements on the source of the PET base film, and a commercially available PET base film known to those skilled in the art and used as the back film of a solar cell can be used.

[0020] In the present invention, the voltage of the corona treatment is preferably 6 to 9KV, more preferably 6.5 to 8.5KV, more preferably 7 to 8KV; the time of the corona treatment is preferably 0.5 to 2s, more preferably 1 ~2s, more preferably 1~1.5s. In the present invention, the corona treatment can effectively improve the surface tension of the base film. During the dip coating process, the dip coating liquid can be fully spread on the surface of ...

Embodiment 1

[0041] In parts by mass, 100 parts of phenolic resin 2402, 55 parts of rutile type titanium dioxide, 10 parts of hexamethylenetetramine and 70 parts of xylene were mixed to obtain a dip coating liquid. The PET base film was dip-coated in the dip coating solution at room temperature for 30 s, and the dip-coating speed was 0.75 m / min; the base film after dip-coating was heated at 120° C. for 12 min to obtain a solar cell back film.

Embodiment 2

[0043] In parts by mass, 100 parts of epoxy resin E-51, 55 parts of rutile type titanium dioxide, 15 parts of triethanolamine and 60 parts of xylene were mixed to obtain the first dip coating solution; at 20 ° C, the PET base film was mixed. Dip coating in the first dip coating solution for 30 s, and the dip coating speed is 0.75 m / min; the base film obtained by the first dip coating is heated at 100° C. for 10 min, and cooled to room temperature under air.

[0044] In parts by mass, 100 parts of phenolic resin 2402, 50 parts of rutile type titanium dioxide, 20 parts of hexamethylenetetramine and 65 parts of xylene were mixed to obtain a dip coating liquid. The PET base film was dip-coated in the dip-coating solution at room temperature for 50 s, and the dip-coating speed was 0.85 m / min; the base film after dip-coating was heated at 110° C. for 10 min to obtain a solar cell back film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com