Method of preparing super light electromagnetic shielding composite materials

A technology of electromagnetic shielding and composite materials, applied in shielding materials, magnetic field/electric field shielding, electrical components, etc., can solve problems such as reducing the mechanical properties of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

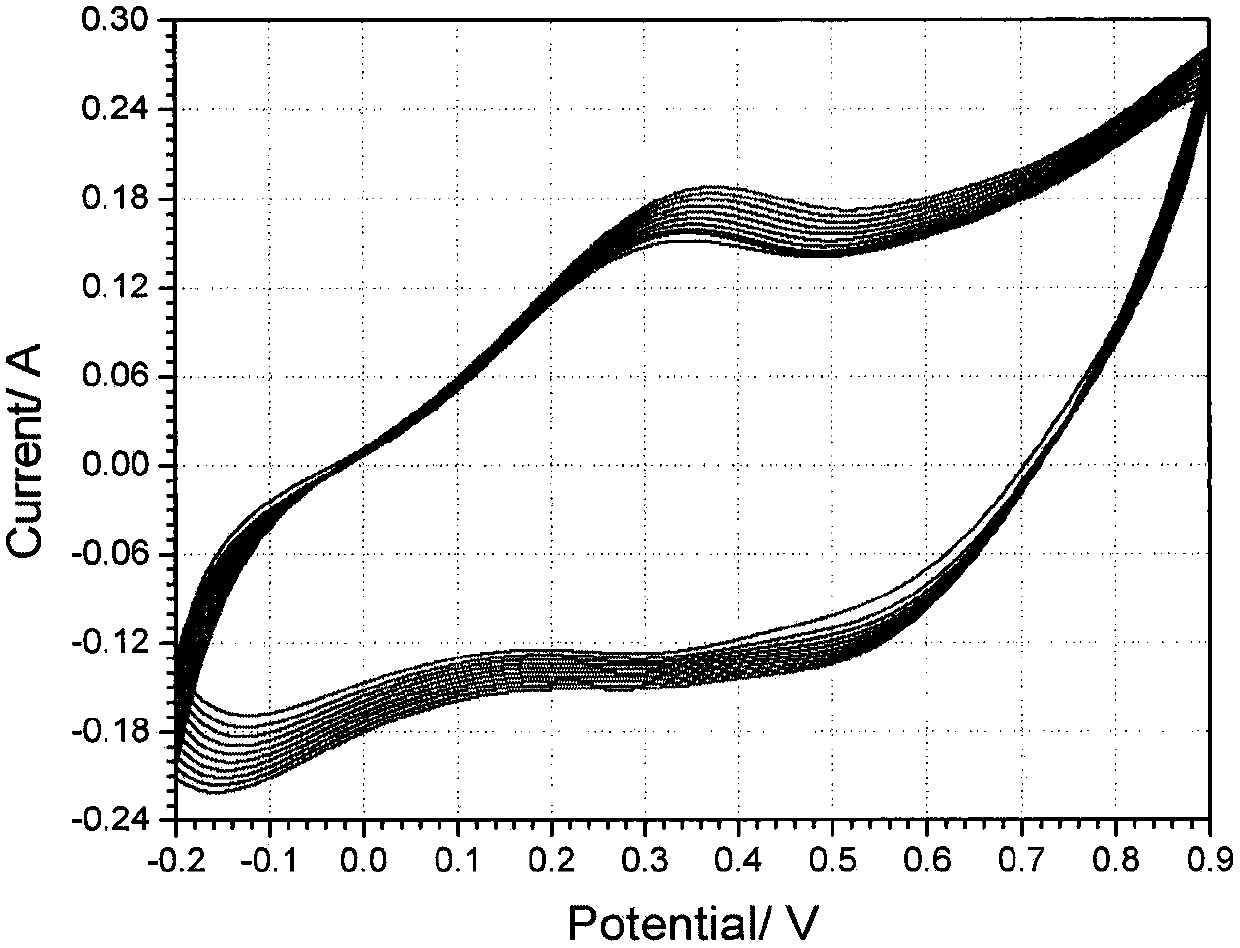

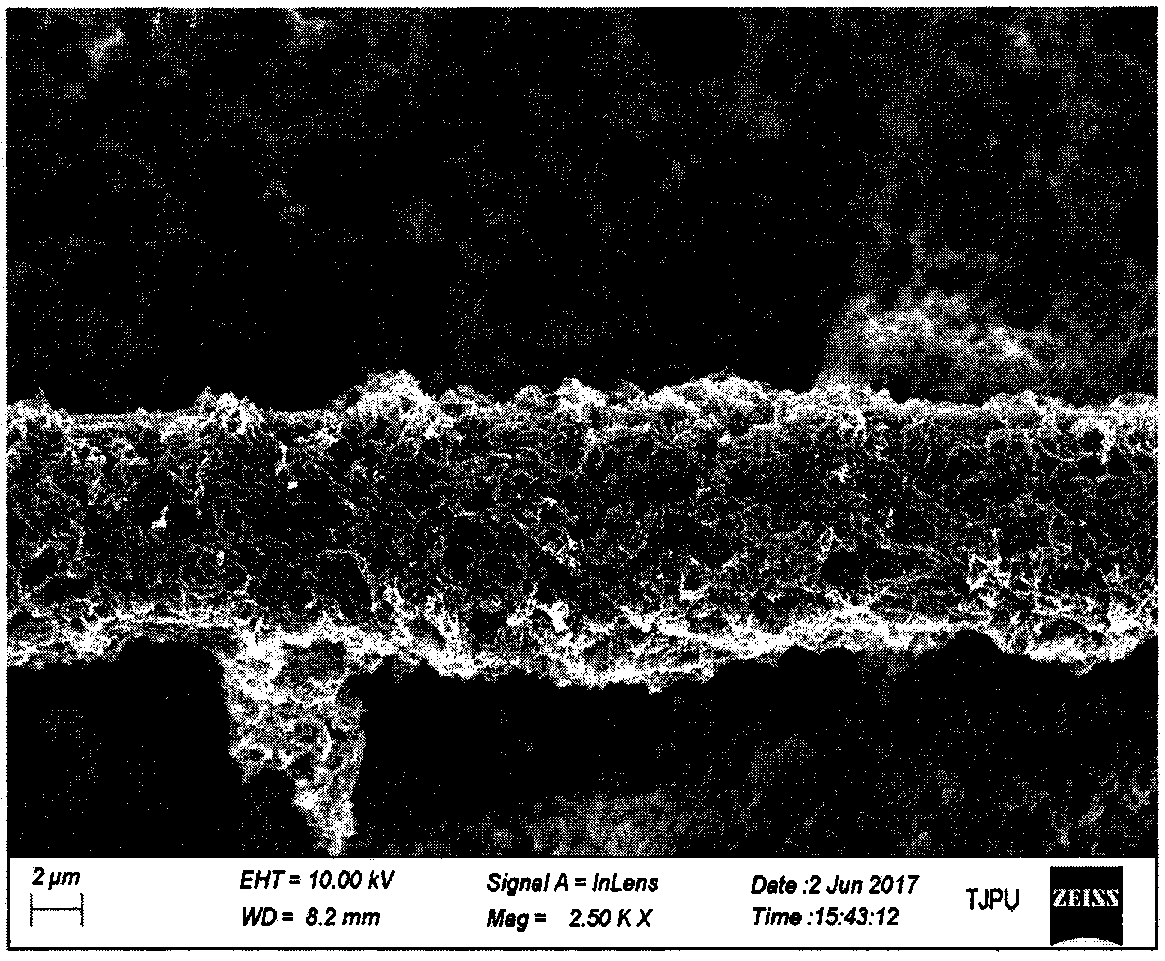

[0016] Soak the carbon paper in ethanol solution for 1 h, then take it out and dry it. Immerse the cleaned and dried carbon paper in the electrolyte solution for 1 h, in which the concentration of aniline monomer is 0.2 mol / L, and the concentration of hydrochloric acid is 1 mol / L. Then, under the three-electrode system (the working electrode is carbon paper impregnated with electrolyte, the counter electrode is carbon rod, and the reference electrode is a saturated calomel electrode), cyclic voltammetry is adopted, the working potential is -0.2 ~ 0.9V, and the scanning rate is 50mV / S, the obtained cyclic voltammetry curve is as follows figure 1 As shown, the reaction temperature of the system is 25°C, the reaction time is 15 minutes, and a conductive polyaniline fiber network is formed on the carbon paper. The carbon paper-polyaniline composite structure was washed several times in water and ethanol, and then dried, such as figure 2 shown.

[0017] The above-prepared carbo...

Embodiment 2

[0019] The carbon paper was soaked in acetone solution and ultrasonically cleaned for 0.5 h, and then taken out for drying. Then soak the cleaned and dried carbon paper in the electrolyte for 2 hours, in which the concentration of aniline monomer is 0.5 mol / L, and the concentration of sulfuric acid is 0.5 mol / L. Then under the three-electrode system (the working electrode is carbon paper impregnated with electrolyte, the counter electrode is a platinum sheet, and the reference electrode is a saturated calomel electrode), the constant current method is adopted, and the sample current density is 2mA / cm 2 , the scanning rate is 25mV / S, the reaction temperature of the system is 20°C, and the reaction time is 10 minutes, and the conductive polyaniline fiber network is polymerized on the carbon paper. Then the carbon paper-polyaniline composite structure was rinsed several times in water and ethanol, and dried.

[0020] The above-prepared carbon paper-polyaniline composite structur...

Embodiment 3

[0022] Soak the carbon paper in ethyl acetate solution and ultrasonically clean it for 1 h, then take it out and dry it. Then soak the cleaned and dried carbon paper in the electrolyte for 1 h, in which the concentration of aniline monomer is 0.75 mol / L, and the concentration of nitric acid is 1 mol / L. Then under the three-electrode system (the working electrode is carbon paper impregnated with electrolyte, the counter electrode is carbon rod, and the reference electrode is silver chloride electrode), the constant potential method is adopted, the sample potential is 0.75V, and the scanning rate is 50mV / S , the system reaction temperature is 28° C., and the reaction time is 20 minutes, and the conductive polyaniline fiber network is polymerized on the carbon paper. Then the carbon paper-polyaniline composite structure was rinsed several times in water and ethanol, and dried.

[0023] The carbon paper-polyaniline composite structure prepared above was combined with conductive e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com