Preparation method and application of nitrogen-doped porous graphene

A porous graphene and nitrogen-doped technology, which is applied in the fields of new nano-carbon materials, nano-devices, lithium-ion batteries, and supercapacitors, can solve the problems of harsh preparation methods and achieve the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of nitrogen-doped porous graphene, comprising the steps of:

[0030] Step 1: Mix graphene and / or modified graphene and etchant evenly in an aqueous solution, place them in a closed container with nitrogen-containing compounds after drying, and keep warm at 50-200°C for 30 minutes;

[0031] Step 2: put the airtight container in step 1 into a microwave oven to react for a few seconds, and perform acid treatment after the reaction to obtain nitrogen-doped porous graphene.

[0032] In an embodiment, graphene and / or modified graphene are heated with etchant and nitrogen-containing compound by microwave, so that graphene and / or modified graphene are reacted with etchant and nitrogen-containing compound, and the modified graphene It is preferably graphene oxide or fluorinated graphene, and the etchant is a metal compound. If it is modified graphene, such as graphene oxide or fluorinated graphene, etc., the active functional groups on its surface can great...

Embodiment 1

[0035] (1) Mix graphene and cobalt nitrate in an aqueous solution according to the mass ratio of 1:1, freeze-dry to obtain the mixture; place the mixture and ammonium carbonate in a closed container, wherein the mass ratio of graphene and ammonium carbonate is 1: 2. Heat to 100°C and hold for 30 minutes;

[0036] (2) Put the above-mentioned airtight container in a microwave oven, and heat it in microwave for 5s with a power of 1000 W;

[0037] (3) After the reaction, the product was treated in dilute hydrochloric acid, washed and dried to obtain nitrogen-doped porous graphene.

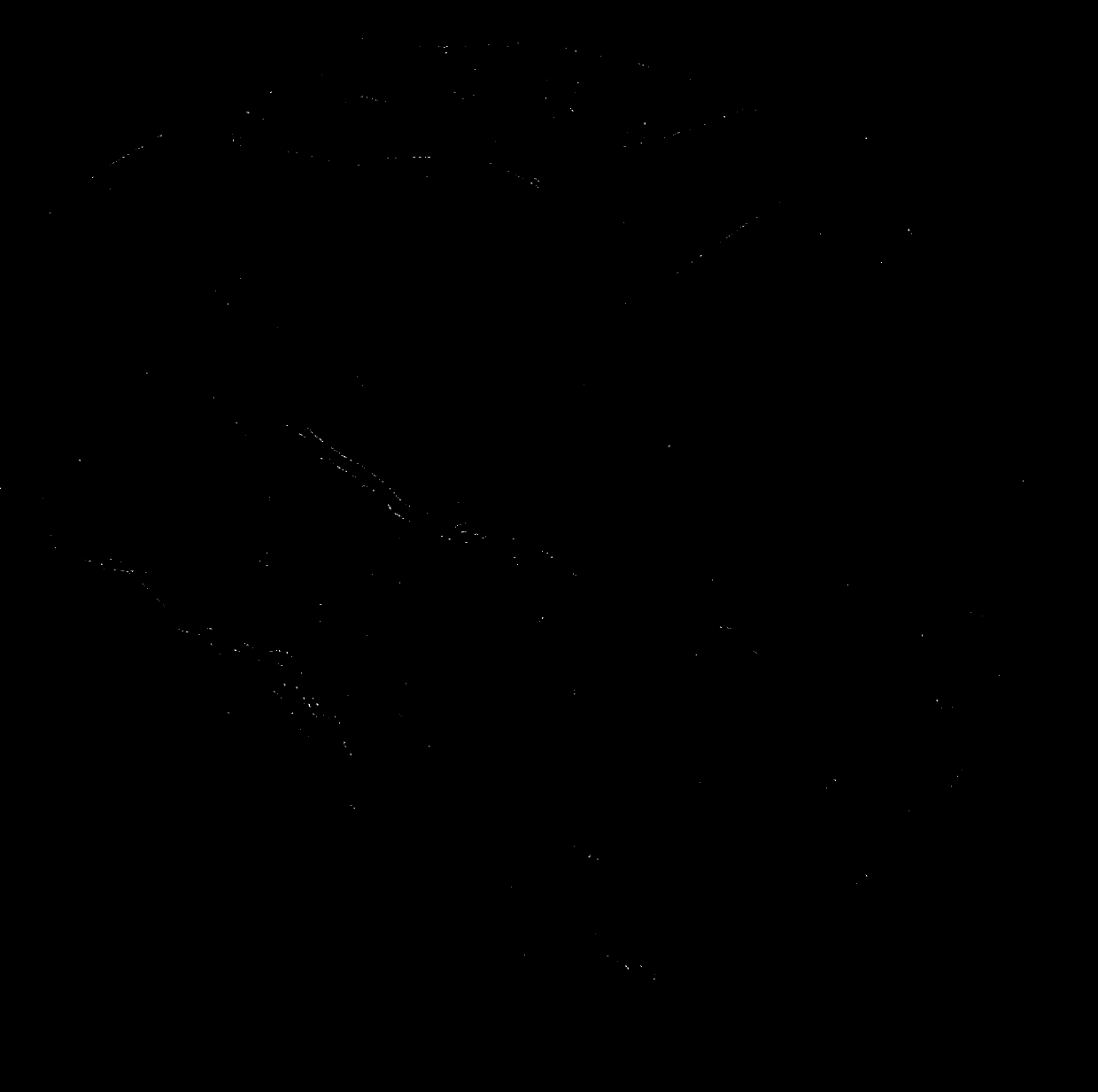

[0038] figure 1 For the transmission electron micrograph of the nitrogen-doped porous graphene prepared in this example, uniform pores are distributed on the surface of the graphene, and the diameter of the porous graphene is about 50 nm.

Embodiment 2

[0040] (1) Mix graphene oxide and nickel acetate in an aqueous solution at a mass ratio of 1:3, and dry the mixture in a vacuum oven at 40°C; place the mixture and ammonium bicarbonate in a closed container, in which graphene oxide and carbonic acid The mass ratio of ammonium hydrogen is 1:5, heated to 90°C and kept for 30min;

[0041] (2) Put the above-mentioned airtight container in a microwave oven, and heat it with a microwave for 10s at a power of 800 W;

[0042] (3) After the reaction, the product was treated in dilute sulfuric acid, washed and dried to obtain nitrogen-doped porous graphene.

[0043] figure 2 The scanning electron micrographs of the nitrogen-doped porous graphene prepared for this example before acid treatment, it can be seen that there are a large number of nano-nickel particles and uniformly distributed nanopores on the surface of the graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com