Granular sludge preparation method and domestic sewage treatment method

A granular sludge and domestic sewage technology, applied in water/sludge/sewage treatment, biological water/sewage treatment, sustainable biological treatment, etc., can solve the problems of easy clogging of membrane pores and high operating costs, and achieve compact structure, Good settling performance and the effect of reducing membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

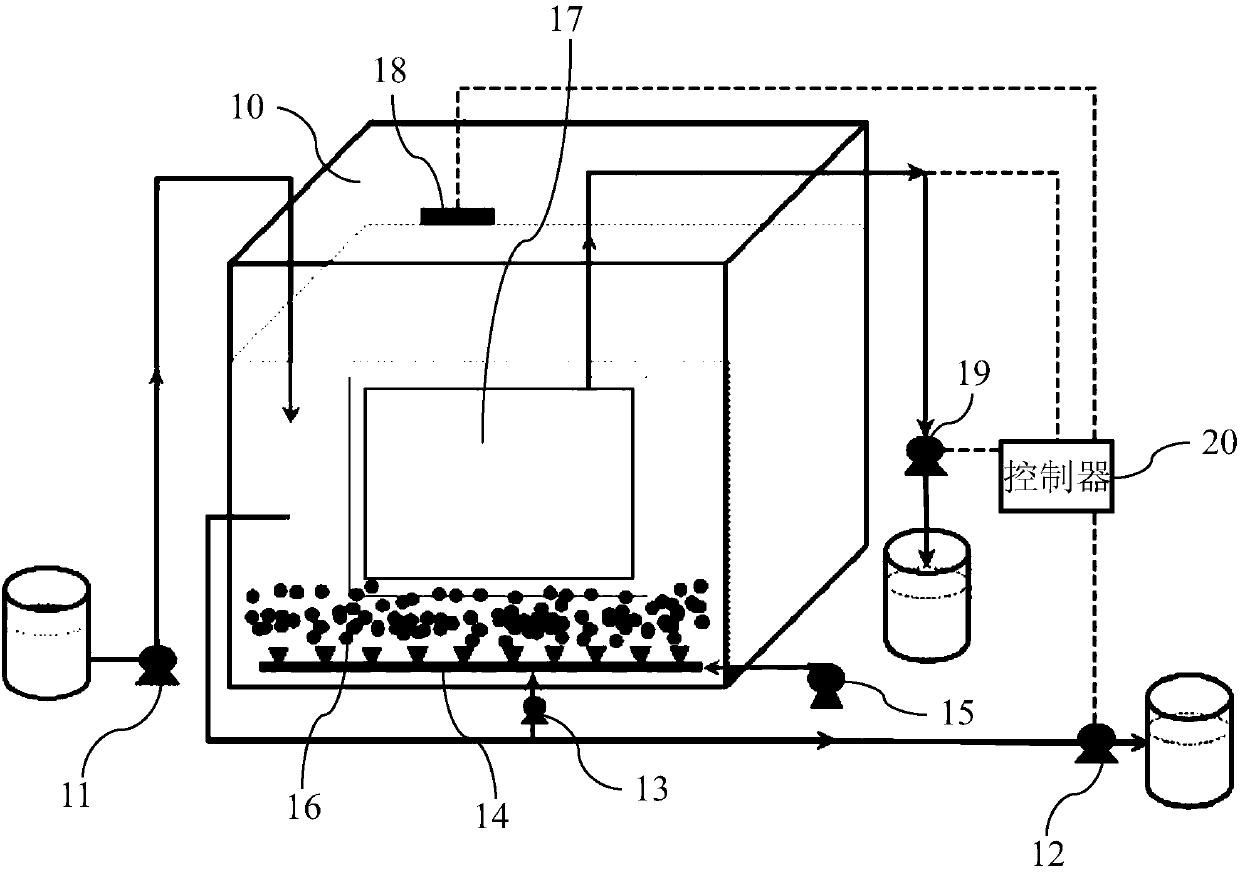

[0032] Granular sludge preparation method of the present invention comprises the following steps:

[0033] (a) in the reactor (such as figure 1 The membrane bioreactor shown) was inoculated with flocculent sludge from the secondary sedimentation tank of domestic sewage plant. Specifically, in this step, the sludge concentration in the reactor after inoculating the flocculent sludge is greater than 8 g-MLSS / L. Of course, the sludge concentration in the reactor can also be greater or less than the above value, but it will affect the time for the formation of granular sludge.

[0034] (b) passing artificial waste water (i.e. artificially prepared water) through the reactor (e.g. figure 1 container 10) in the reactor, while the water in the reactor is intermittently aerated, and the artificial waste water contains glucose at a concentration of 200-500mg / L, ammonium sulfate at a concentration of 60-230mg / L, and ammonium sulfate at a concentration of 40-110mg / L L of potassium dih...

Embodiment 1

[0041] in such as figure 1 The membrane biosludge reactor shown was initially inoculated with fresh flocculent sludge (that is, activated sludge) from the secondary sedimentation tank of the domestic sewage treatment plant. The flocculent sludge in this example was taken from Guangzhou Lijiao Wastewater Treatment Plant. , figure 2 The picture on the upper left in the figure is the fresh flocculent sludge just inoculated.

[0042] In the initial stage of the experiment, the influent water contained 500mg / L of glucose, 230mg / L of ammonium sulfate, and 110mg / L of potassium dihydrogen phosphate, and the strains with denitrification and phosphorus removal functions were quickly screened out. The aeration method was: aeration for 4h-under anoxic conditions Static 4h-aeration 4h, as a cycle of aerobic / anoxic alternating process, using perforated aeration. At the same time, a certain amount of trace element nutrient solution (mixed with the incoming water) is added to the incoming ...

Embodiment 2

[0045] also adopted figure 1 The integrated membrane bio-sludge reactor wastewater treatment system is used to inoculate the flocculent sludge in the secondary sedimentation tank of domestic sewage plant, cultivate granular sludge and treat artificial simulated wastewater.

[0046] Artificial waste water is used as the influent. In the initial stage of the reactor, the influent water contains 500mg / L of glucose, 230mg / L of ammonium sulfate, and 110mg / L of potassium dihydrogen phosphate. It adopts aeration for 4h-under anoxic condition for 4h-aeration 4h cycle alternate operation mode, the operation time is 45 days. The average ammonia nitrogen removal efficiency reaches 95.8%, the total nitrogen removal efficiency reaches 75.3%, the phosphorus removal efficiency reaches 70%, and the influent organic matter removal rate reaches 95%.

[0047] In the second stage, keep the aeration method unchanged, the influent water includes 200mg / L of glucose, 60mg / L of ammonium sulfate, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com