Cement-based cementitious material early-strength type composition dispersant

A technology of cementitious materials and compositions, which is applied in the field of early-strength composition dispersants for cement-based cementitious materials, and can solve the problems of early-strength agents such as cost performance and single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

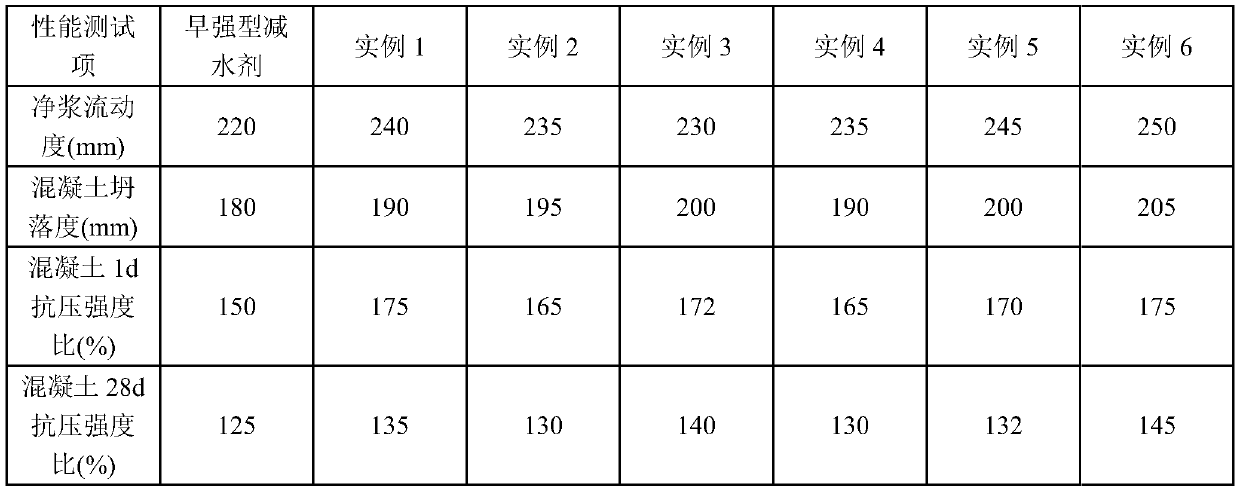

Examples

Embodiment 2

[0056] A preparation method of a cement-based cementitious material early-strength type composition dispersant, the dispersant is formed by mixing and stirring the following semi-finished products in terms of weight percentage:

[0057] Alkanolamine iron aluminum complex: 12%;

[0058] Cationic polymer: 5%;

[0059] Metal ion chelating agent: 1.0%;

[0060] Metal sulfate: 20%;

[0061] The balance is water.

[0062] The metal ion chelating agent: 2-phosphonic acid butane-1,2,4-tricarboxylic acid.

[0063] Described metal sulfate: ferrous sulfate.

[0064] The alkanolamine iron-aluminum complex is formed by polymerizing the following components according to the total mass fraction of 100 parts, and the preparation method is as follows:

[0065] 1) Add 1 part of the composition of sulfuric acid and phosphoric acid with a mass ratio of 1:2, 0.2 parts of diethylene triamine pentacarboxylate, 10.6 parts of ferrous sulfate, 16 parts of aluminum sulfate and 45 parts of water int...

Embodiment 3

[0074] A preparation method of a cement-based cementitious material early-strength type composition dispersant, the dispersant is formed by mixing and stirring the following semi-finished products in terms of weight percentage:

[0075] Alkanolamine iron aluminum complex: 15%;

[0076] Cationic polymer: 2%;

[0077] Metal ion chelating agent: 1.5%;

[0078] Metal Sulfates: 17%.

[0079] The balance is water.

[0080] The metal ion chelating agent: bis-1,6-hexamethylenetriaminepentamethylenephosphonic acid.

[0081] Described metal sulfate: magnesium sulfate.

[0082] The alkanolamine iron-aluminum complex is formed by polymerizing the following components according to the total mass fraction of 100 parts, and the preparation method is as follows:

[0083] The preparation of the alkanolamine iron-aluminum complex is characterized in that: the alkanolamine iron-aluminum complex is polymerized from the following components by mass percentage, the total mass is 100, and the p...

Embodiment 4

[0094]A preparation method of a cement-based cementitious material early-strength type composition dispersant, the dispersant is formed by mixing and stirring the following semi-finished products in terms of weight percentage:

[0095] Alkanolamine iron aluminum complex: 13.5%;

[0096] Cationic polymer: 4%;

[0097] Metal ion chelating agent: 2.0%;

[0098] Metal sulfate: 15%;

[0099] The balance is water.

[0100] Described metal ion chelating agent: hydroxyethylidene diphosphonic acid;

[0101] The metal sulfate: in zinc sulfate.

[0102] The alkanolamine iron-aluminum complex is formed by polymerizing the following components according to the total mass fraction of 100 parts, and the preparation method is as follows:

[0103] 1) Add 1 part of a composition of sulfuric acid and phosphoric acid with a mass ratio of 1:2, 0.2 parts of diethylene triamine pentacarboxylate, 6.7 parts of ferrous sulfate, 19 parts of aluminum sulfate and 55 parts of water into the reactor, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com