Production method and apparatus of hollow granular water-soluble fertilizer

A technology of water-soluble fertilizer and production method, which is applied in the direction of fertilization device, alkaline orthophosphate fertilizer, fertilizer form, etc., can solve the problems such as the influence of soil fertility, and achieve the effect of fast dissolution speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

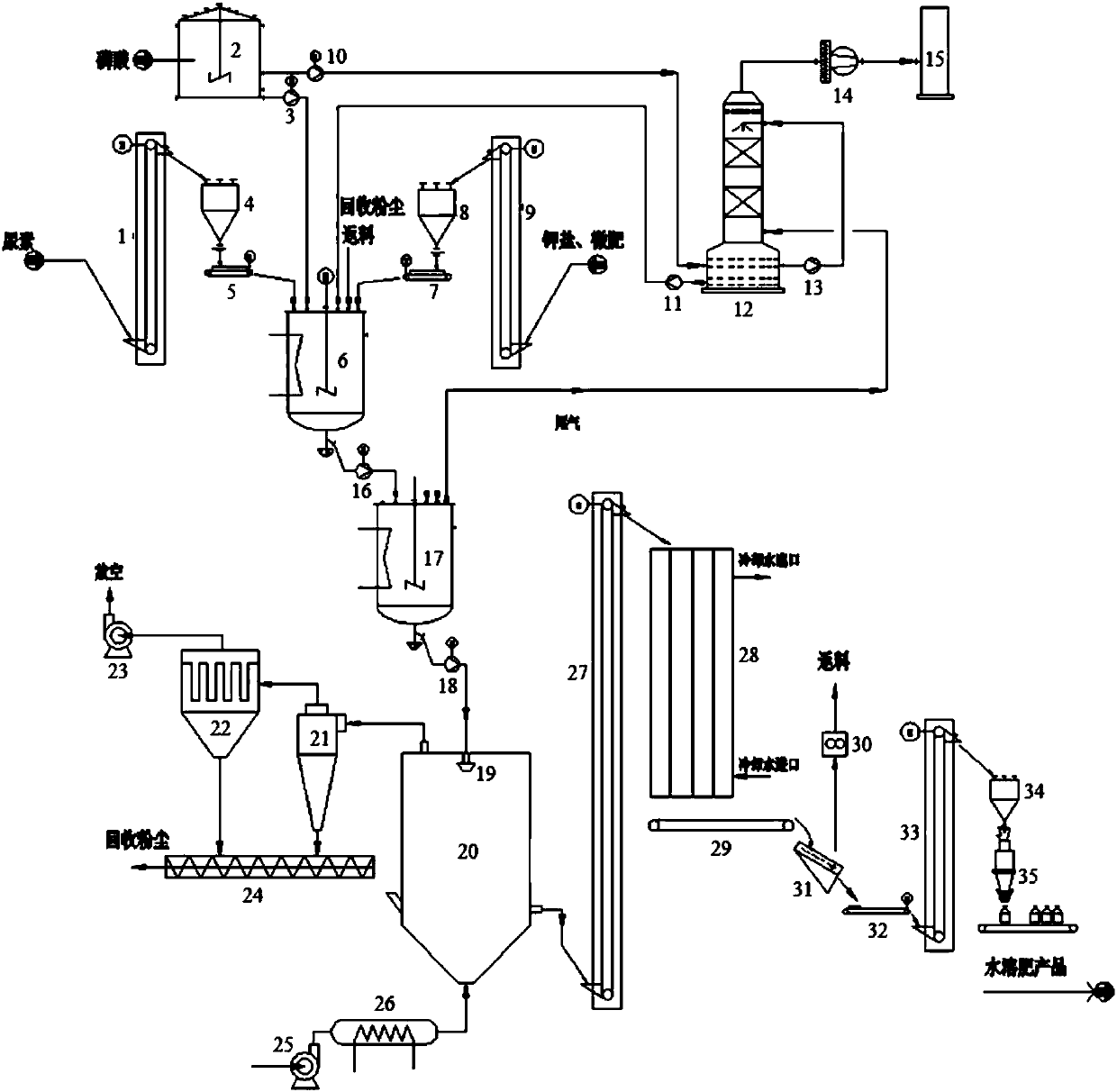

Image

Examples

Embodiment 1

[0034] A method for producing a hollow granular water-soluble fertilizer, the method specifically comprises the following steps:

[0035] 1) Pre-mixing: Add urea and phosphoric acid to the mixer at a molar ratio of 0.9:1, and add potassium salt and micro-fertilizer, and mix at 60°C to prepare a mixed slurry. The mass percentage of potassium salt in the mixed slurry is 9 %, the mass percentage of micro-fertilizer is 1%;

[0036] 2) Foaming reaction: Add the mixed slurry into the foamer, react and foam at 140°C for 5 minutes, and obtain a viscous slurry with a viscosity of 800cp;

[0037] 3) Solidification and granulation: Pour the viscous slurry into the rotary differential nozzle with a nozzle diameter of 0.5mm. The slurry is dispersed into droplets under the action of the nozzle. During the descending process in the container, it exchanges heat with the hot air countercurrently. The phosphoric acid, urea and their intermediate products in the droplets continue to polymerize ...

Embodiment 2

[0045] A method for producing a hollow granular water-soluble fertilizer, the method specifically comprises the following steps:

[0046] 1) Pre-mixing: Add urea and phosphoric acid to the mixer at a molar ratio of 1.5:1, and add potassium salt and micro-fertilizer, and mix at 90°C to prepare a mixed slurry. The mass percentage of potassium salt in the mixed slurry is 29 %, the mass percentage of micro-fertilizer is 1%;

[0047] 2) Foaming reaction: Add the mixed slurry into the foamer, react and foam at 100°C for 15 minutes, and the linear velocity of the end point of the agitator in the foamer is 5m / s to obtain a viscous slurry with a viscosity of 500cp;

[0048] 3) Solidification and granulation: Pour the viscous slurry into the rotary differential nozzle with a nozzle diameter of 2.0mm. The slurry is dispersed into droplets under the action of the nozzle. During the descending process in the container, it exchanges heat with the hot air countercurrently. The phosphoric ac...

Embodiment 3

[0051] A method for producing a hollow granular water-soluble fertilizer, the method specifically comprises the following steps:

[0052] 1) Pre-mixing: Add urea and phosphoric acid to the mixer at a molar ratio of 1.1:1, and add potassium salt and micro-fertilizer, and mix at 65°C to prepare a mixed slurry. The mass percentage of potassium salt in the mixed slurry is 13.5 %, the mass percentage of micro-fertilizer is 0.5%;

[0053] 2) Foaming reaction: Add the mixed slurry into the foamer, react and foam at 130°C for 7 minutes, and obtain a viscous slurry with a viscosity of 1000cp;

[0054] 3) Solidification and granulation: Pour the viscous slurry into the rotary differential nozzle with a nozzle diameter of 0.8mm. The slurry is dispersed into droplets under the action of the nozzle. During the descending process in the container, it exchanges heat with the hot air countercurrently. The phosphoric acid, urea and their intermediate products in the droplets continue to polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com