A cationic modified asphalt emulsifier, its preparation method and application

A technology of modified asphalt and cation, which is applied in the cross field of road industry and applied chemistry, can solve the problems that emulsifiers are difficult to emulsify modified asphalt, high temperature reaction is required for preparation, and raw material source is unstable, etc. Easy to obtain and improve storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

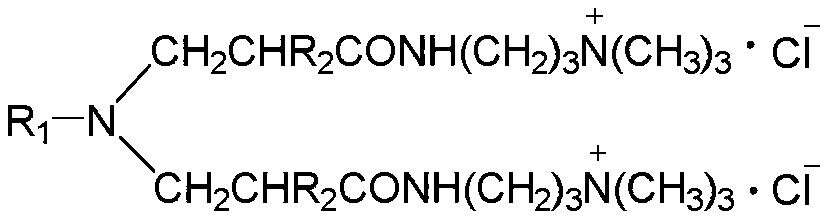

[0035] (1) Preparation of cationic modified asphalt emulsifier

[0036] Add 27.0 g of octadecylamine (0.10 mol) to 27.6 g of ethanol (0.60 mol) to dissolve, then add 84.5 g of acrylamidopropyltrimethylammonium chloride monomer (0.205 mol), and stir and react at 60°C for 6 hours , the cationic modified asphalt emulsifier can be prepared, which is reserved for the emulsified asphalt test.

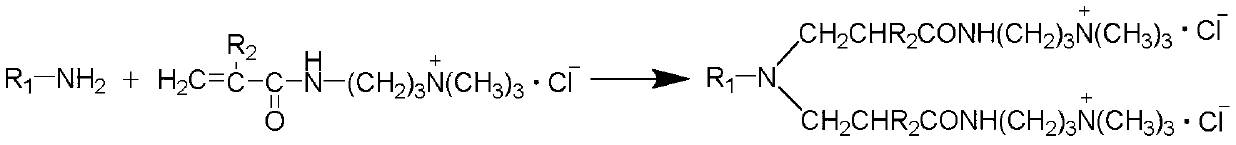

[0037] The reaction equation is as follows:

[0038]

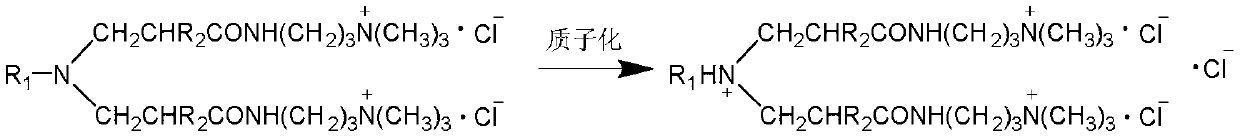

[0039] Wherein, in the process of preparing soap liquid, the above-mentioned emulsifier tertiary amine group will be protonated to a certain extent under acidic environment, further enhancing its water solubility.

[0040] (2) Preparation of cationic modified emulsified asphalt

[0041] Take 7.5g of the cationic modified asphalt emulsifier of this example, add it to an appropriate amount of water, adjust the pH to 2-3 with hydrochloric acid, and prepare 250g of soap liquid; heat the soap liquid to 60°C and add it to a colloid mill, a...

Embodiment 2

[0047] (1) Preparation of cationic modified asphalt emulsifier

[0048] Add 27.0g of octadecylamine (0.10mol) to 23.0g of ethanol (0.50mol) to dissolve, then add 92.6g of methacrylamidopropyltrimethylammonium chloride monomer (0.210mol), and stir the reaction at 50°C After 8 hours, the cationic modified asphalt emulsifier can be prepared, which is reserved for the emulsified asphalt test.

[0049] The reaction equation is as follows:

[0050]

[0051] Wherein, in the process of preparing soap liquid, the above-mentioned emulsifier tertiary amine group will be protonated to a certain extent under acidic environment, further enhancing its water solubility.

[0052] (2) Preparation of cationic modified emulsified asphalt

[0053] Take 10.0g of the cationic modified asphalt emulsifier of this example and add it to an appropriate amount of water, adjust the pH to 2-3 with hydrochloric acid, and prepare 250g of soap liquid; heat the soap liquid to 65°C and add it to a colloid mil...

Embodiment 3

[0060] (1) Preparation of cationic modified asphalt emulsifier

[0061] Add 24.1g of hexadecylamine (0.10mol) into 22.4g of methanol (0.70mol) to dissolve, then add 84.3g of acrylamidopropyltrimethylammonium chloride monomer (0.204mol), and stir and react at 40°C for 12 hours , the cationic modified asphalt emulsifier can be prepared, which is reserved for the emulsified asphalt test.

[0062] The reaction equation is as follows:

[0063]

[0064] Wherein, in the process of preparing soap liquid, the above-mentioned emulsifier tertiary amine group will be protonated to a certain extent under acidic environment, further enhancing its water solubility.

[0065] (2) Preparation of cationic modified emulsified asphalt

[0066] Take 9.0g of the cationic modified asphalt emulsifier of this example and add it to an appropriate amount of water, adjust the pH to 2-3 with hydrochloric acid, and prepare 250g of soap liquid; heat the soap liquid to 60°C and add it to a colloid mill, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com