Salt-responsive modified polyacrylamide oil displacing agent and preparation method thereof

A technology of polyacrylamide oil displacement agent and acrylamide, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve the problems of poor stability of foam flooding oil displacement agents, immature experimental methods, lack of application and practice, etc. problems, to achieve the effects of enhanced oil recovery, good responsiveness, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a salt-responsive modified polyacrylamide oil-displacing agent, which is prepared according to the following steps:

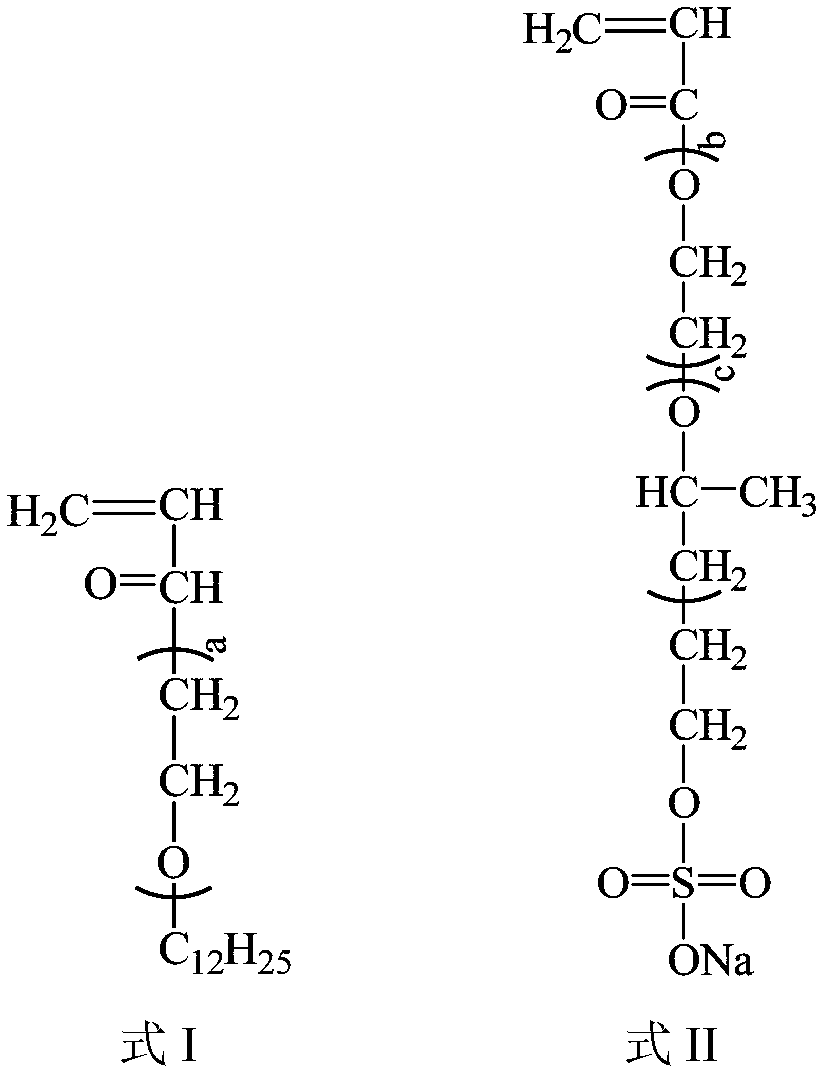

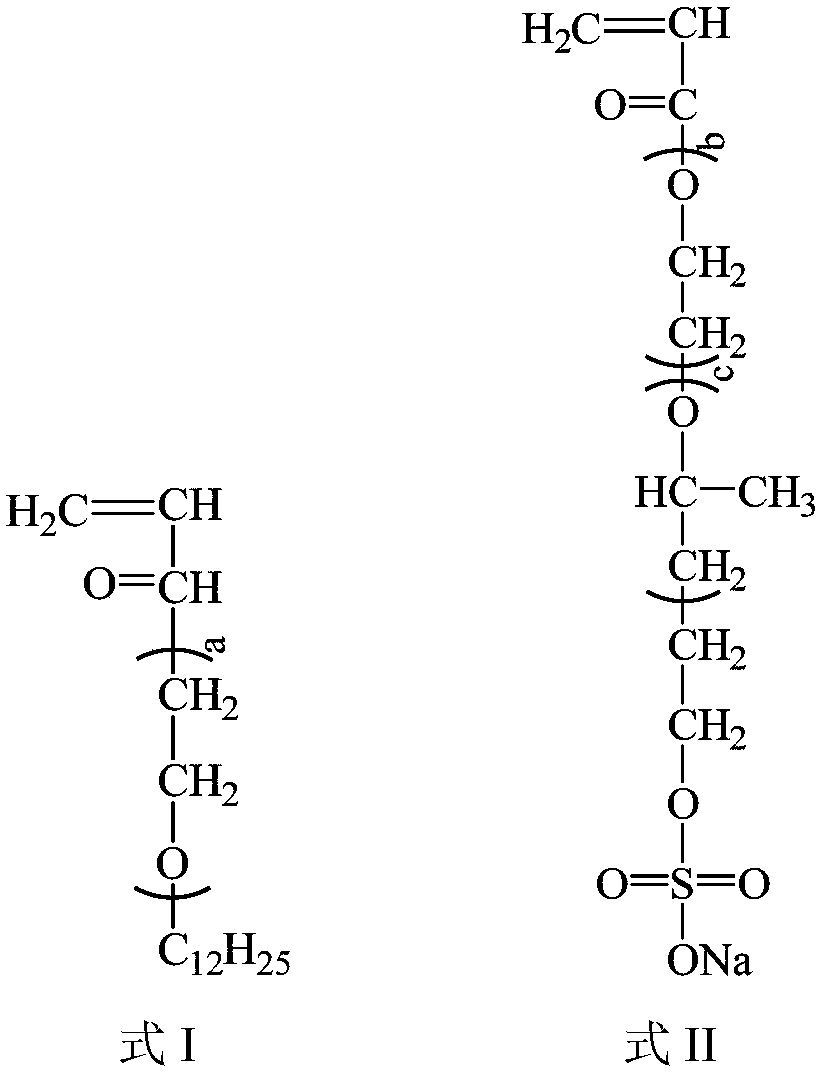

[0031] The percentages of the various comonomers used in the synthetic salt-responsive modified polyacrylamide oil displacing agent to the total mass of the comonomers are: acrylamide 60%, sodium acrylate 30%, and the functional monomer represented by formula III 3% , The functional monomer shown in formula IV is 7%.

[0032]

[0033] The specific preparation method of the functional monomer in formula III is: adding 20 g of acrylic acid and catalyst KOH into the autoclave, heating to 115±5°C, purging and replacing with nitrogen three times, then adding 50 g of ethylene oxide, and controlling the reaction kettle The total internal pressure is 0.2-0.4MPa, and the reaction temperature is 140±5°C. After the pressure in the reactor returns, the reaction is continued for 60 minutes. Add 10 g of dodecyl alcohol, control the pressure in the...

Embodiment 2

[0037] This embodiment provides a salt-responsive modified polyacrylamide oil-displacing agent, which is prepared according to the following steps:

[0038] The percentages of various comonomers used in the synthetic salt-responsive modified polyacrylamide oil-displacing agent in the total mass of comonomers are: 65% of acrylamide, 25% of sodium acrylate, and 4% of functional monomers represented by formula V , The functional monomer shown in formula VI is 6%.

[0039]

[0040] The specific preparation method of the functional monomer in formula V is: adding 20 g of acrylic acid and catalyst KOH into the autoclave, heating to 115±5°C, purging and replacing with nitrogen three times, then adding 50 g of ethylene oxide, and controlling the reaction kettle The total internal pressure is 0.2-0.4MPa, and the reaction temperature is 140±5°C. After the pressure in the reactor returns, the reaction is continued for 60 minutes. Add 10 g of dodecanol, control the pressure in the reactor to ...

Embodiment 3

[0044] This embodiment provides a salt-responsive modified polyacrylamide oil-displacing agent, which is prepared according to the following steps:

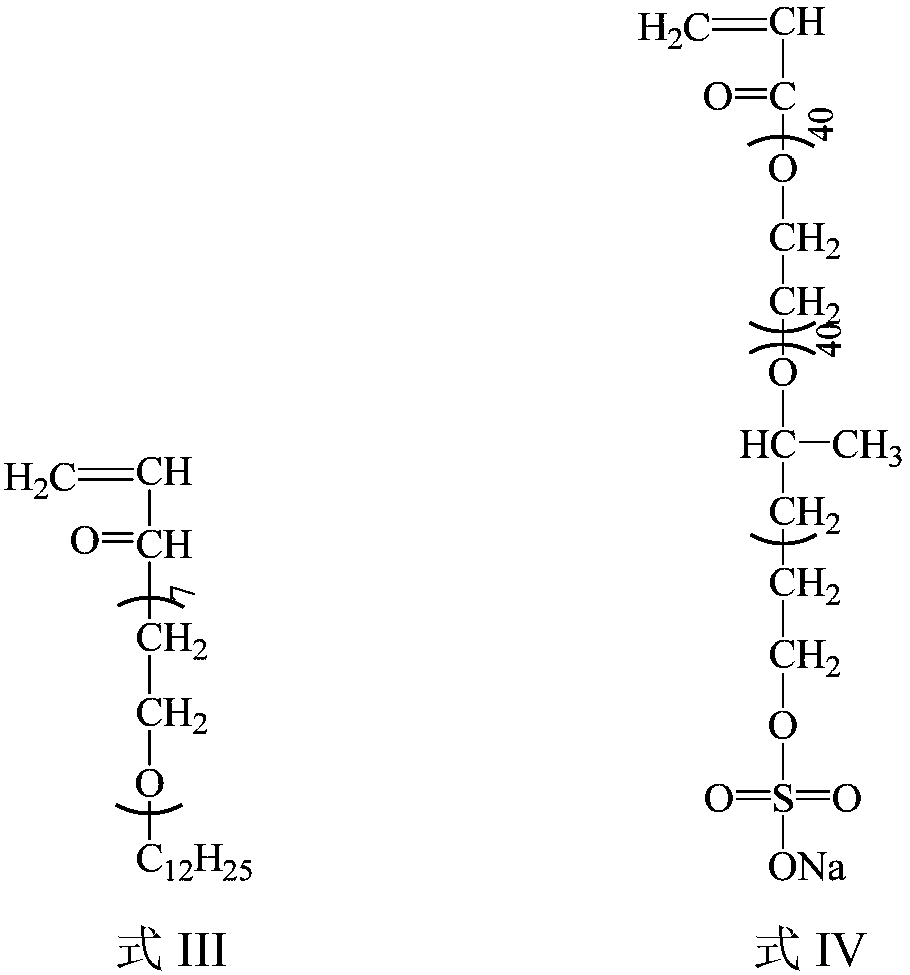

[0045] The percentages of various comonomers used in the synthetic salt-responsive modified polyacrylamide oil displacing agent to the total mass of comonomers are: acrylamide 50%, acrylic acid 35%, and the functional monomer represented by formula VII 5%. The functional monomer represented by formula VIII is 10%.

[0046]

[0047]

[0048] The specific preparation method of the functional monomer in formula VII is: adding 20 g of acrylic acid and catalyst KOH into the autoclave, heating to 115±5°C, purging and replacing it with nitrogen three times, then adding 100 g of ethylene oxide, and controlling the reactor The total internal pressure is 0.2-0.4MPa, and the reaction temperature is 140±5°C. After the pressure in the reactor returns, the reaction is continued for 60 minutes. Add 10 g of dodecanol, control the pressure in the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com