A method for preparing shortened dry-state fermented vegetables

A technology for fermenting vegetables in a dry state, which is applied in the field of preparing fermented vegetables in a shortened dry state, which can solve the problems of unsuitable control and long fermentation cycle, and achieve the effects of improving the flavor of sauce, less environmental pollution, and no waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

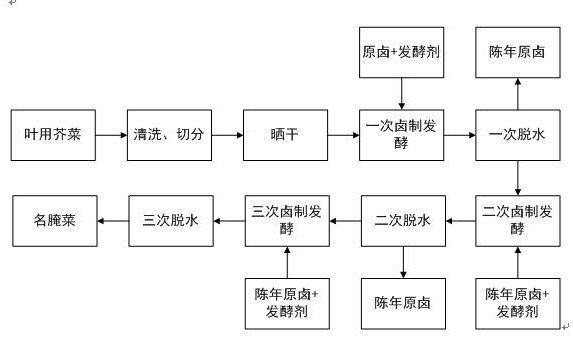

[0038] A method for preparing shortenable dry fermented vegetables, comprising the following steps:

[0039] (1) Select disease-free, rotten fresh leafy greens as raw materials; then wash to remove silt, dust, debris and old skin and old tendons; and use a vegetable cutter to cut the greens into filaments with a size of 2*3cm, Then, the surface and internal water of the mustard greens are removed by the method of natural drying, and the water content of the mustard greens after drying is 40wt%.

[0040](2) Primary brine fermentation: in parts by weight, weigh 100 parts of dried vegetables, 120 parts of raw brine, and 1 part of starter, and carry out sealed fermentation for 12 days; mainly to remove the mustard green flavor. The raw brine formula is composed of the following raw materials by weight: 65 parts of water, 25 parts of soy sauce, 10 parts of salt, 8 parts of white wine, and 2 parts of spice powder. The spice powder is a mixture of star anise powder, cinnamon powder,...

Embodiment 2

[0047] A method for preparing shortenable dry fermented vegetables, comprising the following steps:

[0048] (1) Choose disease-free, rotten fresh leafy greens as the main raw material, and then wash: remove the sand, dust, debris and old skin and tendons, and then use a vegetable cutter to cut the greens into filaments with a size of 2* 3 cm, and continue to remove the surface and internal moisture of the mustard by the method of natural drying, and the moisture content of the mustard after drying is 40wt%.

[0049] (2) Primary brine fermentation: in parts by weight, weigh 100 parts of dried greens, 130 parts of raw brine, and 1 part of starter, and carry out sealed fermentation for 15 days; the main purpose is to remove the raw flavor of mustard greens. The raw brine formula is composed of the following raw materials by mass: 60 parts of water, 30 parts of soy sauce, 10 parts of salt, 8 parts of white wine, and 2 parts of spice powder. The spice powder is a mixture of star ...

Embodiment 3

[0056] A method for preparing shortenable dry fermented vegetables, comprising the following steps:

[0057] (1) Choose disease-free and rotten fresh leafy greens as the main raw material, then wash to remove sediment, dust, debris and old skin and old tendons, and use a vegetable cutter to cut the greens into filaments with a size of 2*3cm , and then through the natural drying method, the surface and internal water of the mustard greens are removed, and the water content of the mustard greens after drying is 40wt%.

[0058] (2) Primary brine fermentation: in parts by weight, weigh 100 parts of dried vegetables, 150 parts of raw brine, and 1 part of starter, and carry out sealed fermentation for 15 days; mainly to remove the mustard green flavor. The raw brine formula is composed of the following raw materials by mass: 60 parts of water, 35 parts of soy sauce, 12 parts of salt, 6 parts of white wine, and 2 parts of spice powder. The spice powder is a mixture of star anise pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com