Low-temperature purification and separation process for fatty acid lower alcohol ester plasticizers based on palm oil

An ester plasticizer, purification and separation technology, used in the preparation of carboxylate, organic chemistry, chemical instruments and methods, etc., can solve the problems of narrow application range and complex process flow, and achieve sufficient and stable sources and simple process methods. , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A low-temperature purification and separation process for fatty acid low-carbon alcohol ester plasticizers based on palm oil, the separation process is the separation method of fatty acid low-carbon alcohol esters and epoxy fatty acid low-carbon alcohol esters generated in the preparation of plasticizers, the method is as follows :

[0029] (1) melting the homemade fatty acid lower alcohol ester or epoxy fatty acid lower alcohol ester at a separation temperature of 30-40° C., and separating and removing the high melting point solid;

[0030] (2) The remaining liquid fatty acid lower alcohol ester or epoxy fatty acid lower alcohol ester is uniformly mixed with the crystallization solvent at a mixing temperature of 20-50°C in a certain volume ratio;

[0031] (3) Control the cooling rate to 0.02-2°C / min. After cooling down to the crystallization temperature of -20-15°C, the cooling rate is 0.02-2°C / min. Keep the temperature and cultivate the crystal for 1-48 hours, and the...

Embodiment 2

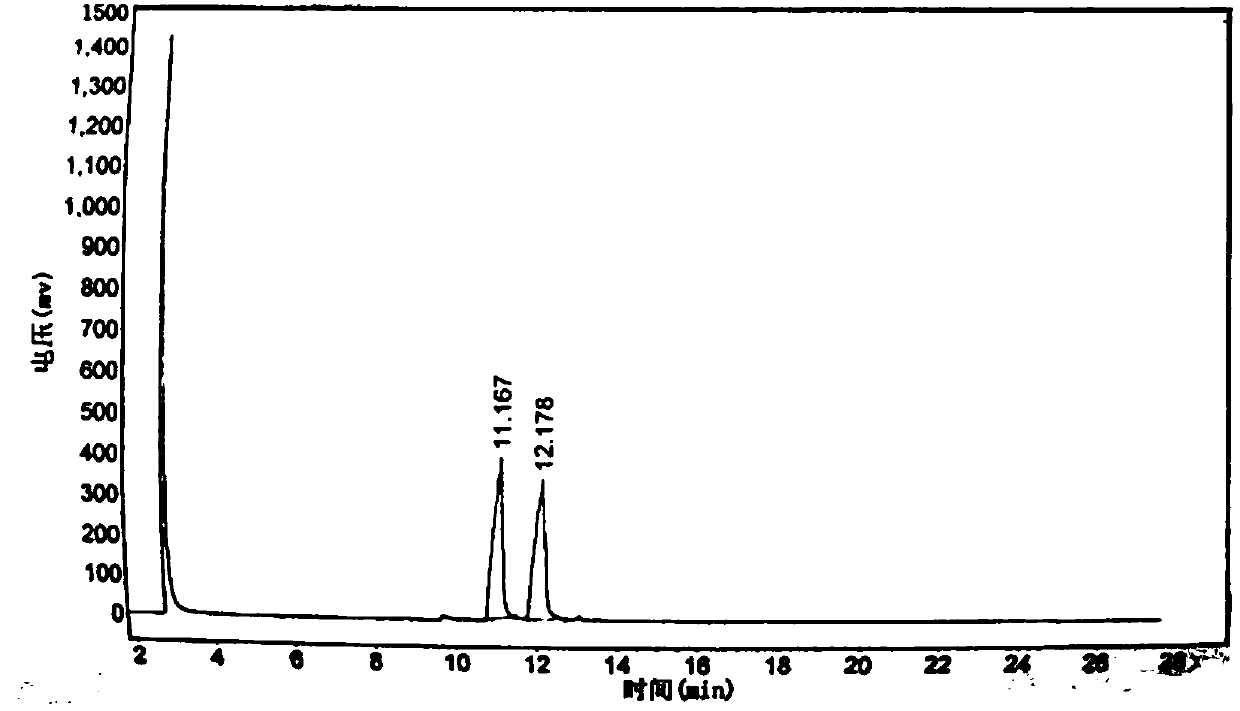

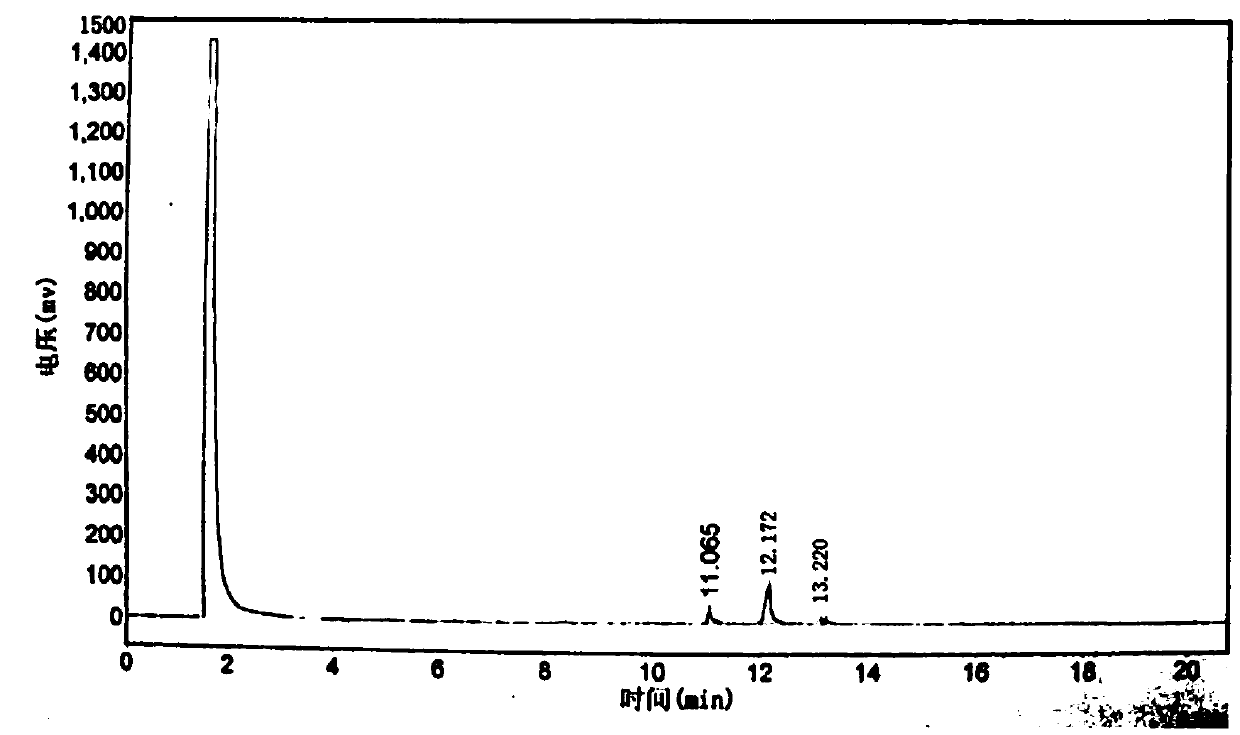

[0041]Add 100 parts of epoxy fatty acid ethyl ester self-made from palm oil into the separation kettle, heat to 30° C., and remove the insoluble solid by suction filtration. Add 2 times the volume of pre-prepared acetone-ethanol solution to the remaining liquid epoxy fatty acid ethyl ester, wherein ethanol accounts for 70 wt%, and the rest is acetone, and mix well at 20°C. Under the condition that the cooling rate is controlled to be 0.5°C / min, the temperature is lowered to 10°C, and the temperature is kept in a water bath at a constant temperature of 10°C for 48 hours, and crystals are precipitated from the solution. Filter and separate the crystal and the solution, wash the crystal with ethanol and dry under reduced pressure to obtain ethyl palmitate with a purity greater than 90%; the solution is distilled under reduced pressure to remove ethanol and acetone to obtain ethyl epoxy fatty acid ethyl ester, wherein the ethyl epoxy oleate content is greater than 90%

Embodiment 3

[0043] Add 100 parts of fatty acid n-decyl esters made by palm oil into the separation kettle, heat to 40° C., and remove the insoluble solids by suction filtration. Add 5 times the volume of pre-prepared butanol solution to the remaining liquid n-decyl fatty acid ester, wherein butanol accounts for 100 wt%, and mix uniformly at 50°C. Under the condition that the cooling rate is controlled at 2°C / min, the temperature is lowered to 15°C, and the temperature is kept in a water bath at a constant temperature of 15°C for 24 hours, and crystals are precipitated from the solution. Centrifuge the crystals and solution, wash the crystals with ethanol and dry under reduced pressure to obtain n-decyl palmitate with a purity of not less than 85%; distill the solution under reduced pressure to remove butanol to obtain n-decyl unsaturated fatty acids, of which n-decyl oleate content Greater than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com