Self-polishing antifouling coating excluding cuprous oxide and organic tin and preparation method thereof

An antifouling paint, cuprous oxide technology, applied in antifouling/underwater paints, paints containing biocides, coatings, etc., can solve the problem of increasing ship maintenance costs, reducing ship voyage rate, and cumbersome preparation process, etc. problems, to achieve the effect of preventing the adhesion of marine organisms, the marine environment is safe and friendly, and the effect of continuous anti-fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

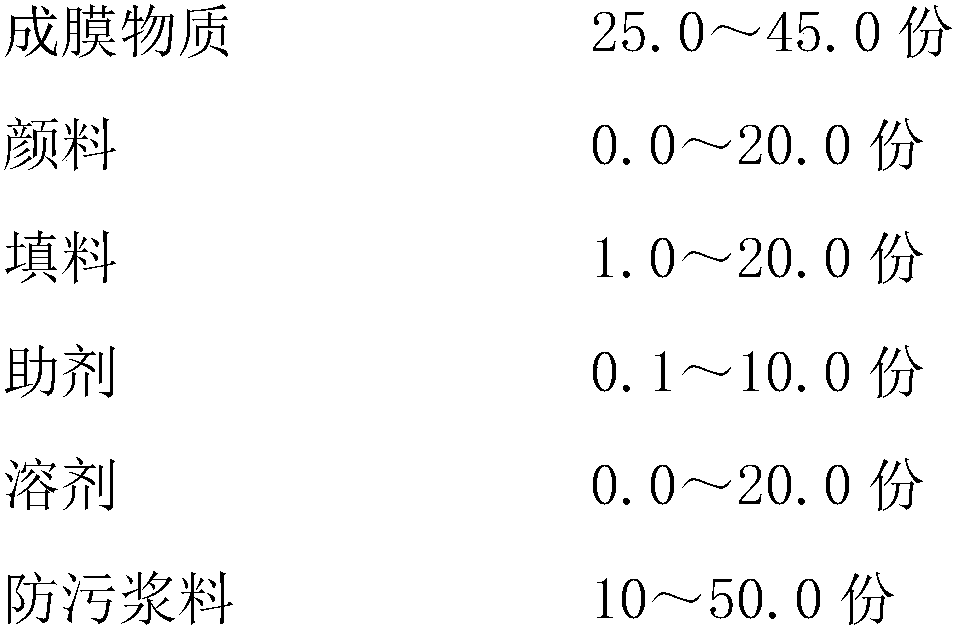

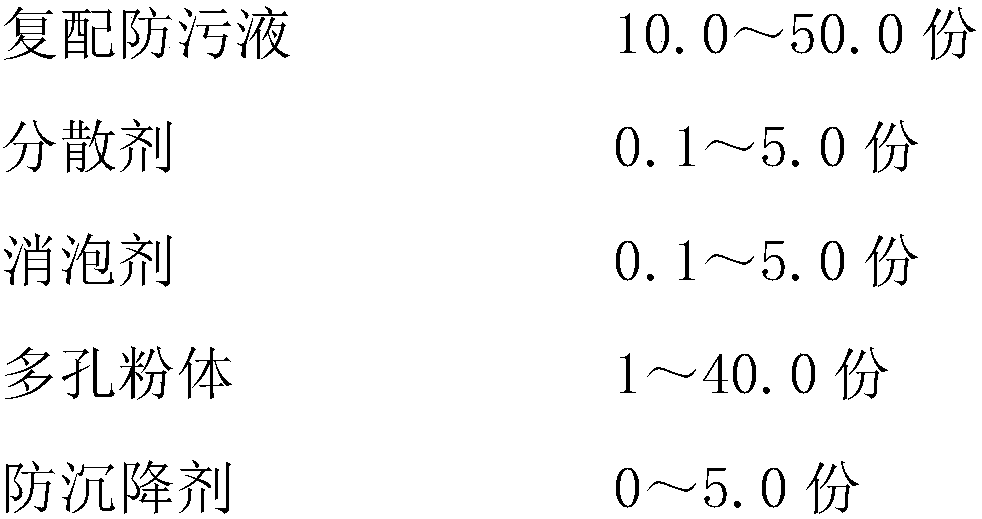

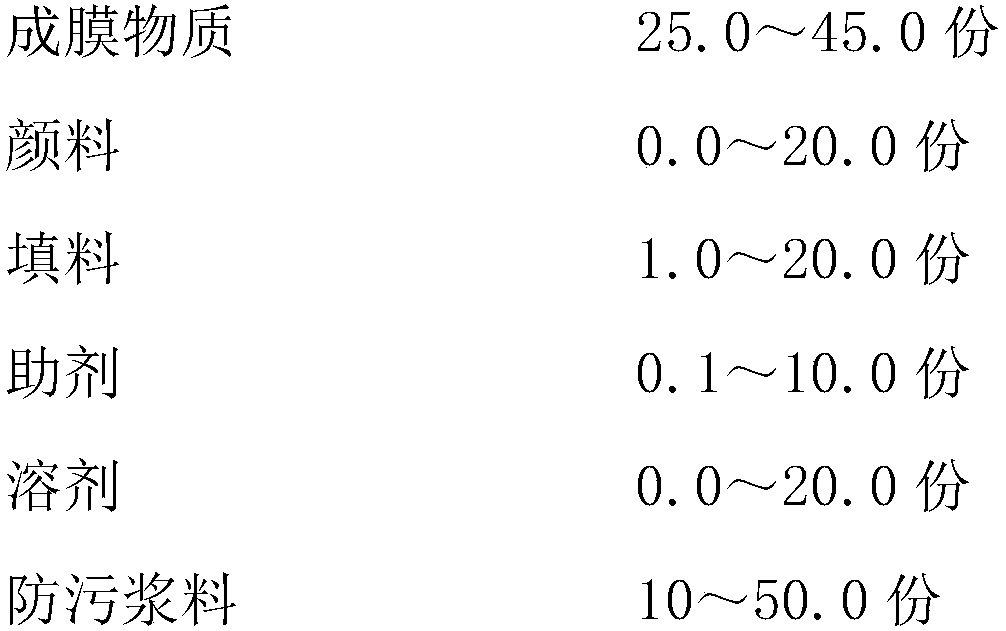

Method used

Image

Examples

Embodiment 1

[0042] 1) Mix and dissolve 10 parts of synthetic capsaicin raw material and 90 parts of environmentally friendly antifouling agent SEA-NINE 211 to make a compound antifouling liquid, and keep it sealed for later use;

[0043] 2) Mix 1 part by mass of dispersant BYK161, 0.5 part by mass of defoamer BYK066N, 30 parts by mass of porous powder diatom powder and 40 parts by mass of compound antifouling liquid, medium speed (600-1000 rpm / Minutes) airtight stirring to disperse evenly, let the compound antifouling liquid fully wet and fill the voids of the porous powder, and then add 1 part of anti-settling agent fumed silica to continue dispersing to make a uniformly dispersed antifouling slurry;

[0044] 3) 30 parts by mass of film-forming material copper acrylate resin, 0.5 parts by mass of dispersant BYK161, 0.5 parts by mass of defoamer Deqian 6800, 18 parts by mass of filler barium sulfate, 5 parts by mass of pigment iron red, 1.5 Add parts by weight of Deqian 837 leveling agen...

Embodiment 2

[0046] 1) Stir and dissolve 10 parts by mass of capsaicin crystal raw material, 20 parts by mass of environmental protection antifouling agent TCPM and 20 parts by mass of xylene as a solvent, prepare a compound antifouling liquid, and keep it sealed for future use;

[0047] 2) Mix 0.5 parts by mass of dispersant BYK163, 1 part by mass of defoamer Deqian 6800, 25 parts by mass of porous powder diatom powder and 45 parts by mass of compound antifouling liquid, medium speed (600-1000 revolutions per minute) closed stirring to disperse evenly, let the compound antifouling liquid fully wet and fill the voids of the porous powder, and then add 1 part of anti-settling agent white carbon black and continue to disperse to form a uniformly dispersed antifouling slurry;

[0048] 3) Add 35 parts by mass of film-forming substance zinc acrylate resin, 0.5 parts by mass of dispersant BYK163, 0.5 parts by mass of defoamer Deqian 6800, 20 parts by mass of filler titanium dioxide, and 1.5 parts...

Embodiment 3

[0050] 1) Mix and dissolve 20 parts of capsicum oleoresin (capsaicin effective content 60%) raw materials, 40 parts of environmental protection antifouling agent DCOIT-30, and 30 parts of TCPM to prepare a compound antifouling Liquid, sealed and kept for later use;

[0051] 2) Mix 0.7 parts by mass of dispersant BYK163, 0.7 parts by mass of defoamer BYK066N, 3 parts by mass of carbon nanotubes and 30 parts by mass of compound antifouling liquid, and stir in a closed manner at a medium speed (600-1000 rpm) Disperse evenly, let the compound antifouling liquid fully wet the filled carbon nanotubes, and disperse to make a uniformly dispersed antifouling slurry;

[0052] 3) 40 parts by mass of film-forming material copper acrylate resin, 0.5 parts by mass of dispersant BYK163, 0.5 parts by mass of defoamer BYK066N, 15 parts by mass of filler alumina, 5 parts by mass of pigment graphite, 1.5 parts by mass of Add BYK358 leveling agent into the batching tank of the disperser in turn,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com