Preparation method of white fabric

A fabric and white technology, applied in the field of white fabric preparation, can solve the problems of easy generation of scratches and creases, large energy consumption and water consumption, unsuitable for green environmental protection, energy saving and consumption reduction in clean production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

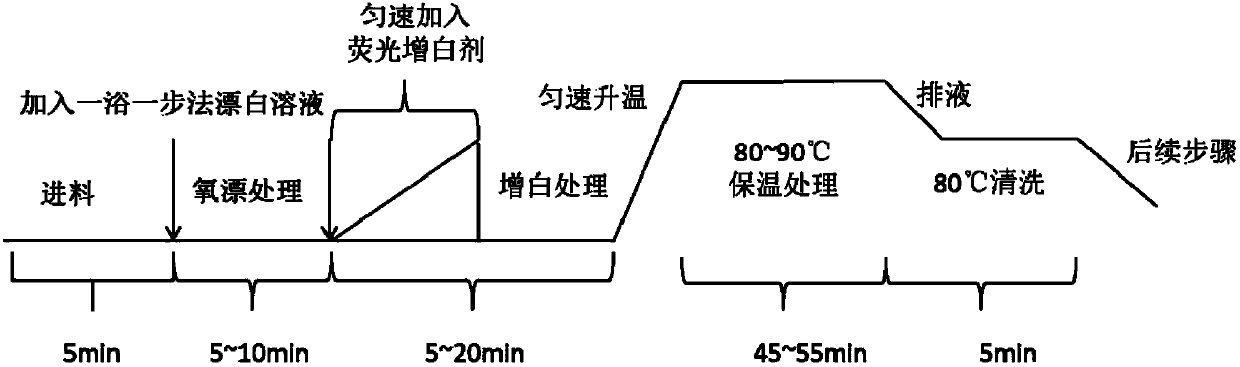

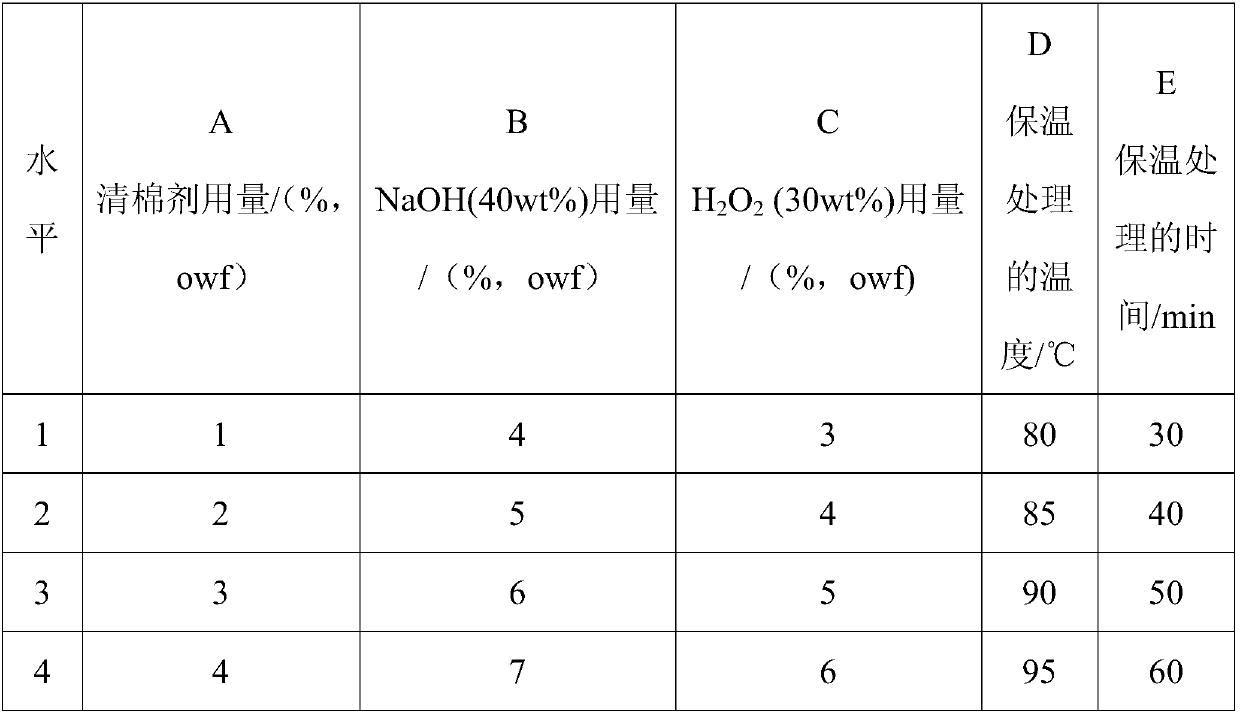

Embodiment 1

[0097] will be 30 S Cotton plain weave, weight 250kg, width 160cm, weight 200g / m 2 The cotton fabric blank is arranged in the THEN type air-flow dyeing machine, and one-bath one-step method bleaching solution is added to the air-flow dyeing machine with a bath ratio of 1:5, and the mixture is uniform, and the one-bath one-step method bleaching solution includes 2g / L permeation Anti-wrinkle agent JFC-1, 1g / L JS-22, 3% (owf) cleaning agent QM-4, 5% (owf) caustic soda (40wt%) and 5% (owf) H 2 o 2 (30wt%), control the pH value of the one-bath one-step bleaching solution at 10~11, stir the mixture for 5min to make it evenly mixed, then the one-bath one-step bleaching solution is atomized and sprayed through the nozzle of the air-flow dyeing machine, and the fabric is Oxygen bleaching treatment, the time of oxygen bleaching treatment is 5min, then add 0.8% (owf) fluorescent whitening agent BHT at a constant flow rate to the one-bath one-step bleaching solution in the airflow dyein...

Embodiment 2

[0099] The only difference from Example 1 is that the amount of fluorescent whitening agent used is 0.5% (owf), and the heating rate of the heat preservation treatment is 1.5° C. / min.

Embodiment 3

[0101] The only difference from Example 1 is that the amount of fluorescent whitening agent used is 0.2% (owf), and the heating rate of the heat preservation treatment is 1° C. / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com