High-solid-content water-based polyether type polyurethane resin and preparation method thereof

A polyether polyurethane, high solid content technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of high processing and baking costs, difficult drying of thick coatings, poor resistance to humidity and heat, etc., and achieve excellent resistance to humidity and heat. Performance, good elasticity, high peel strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

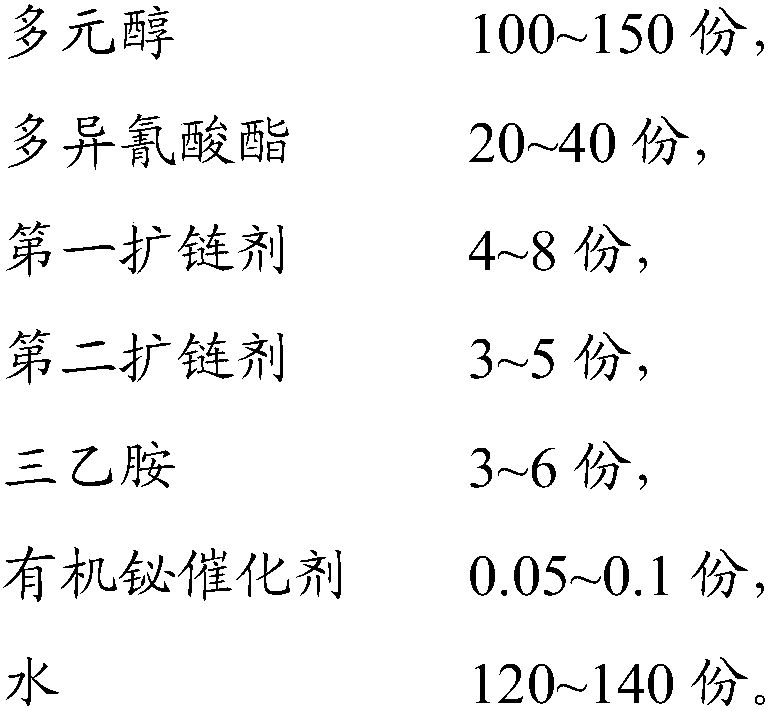

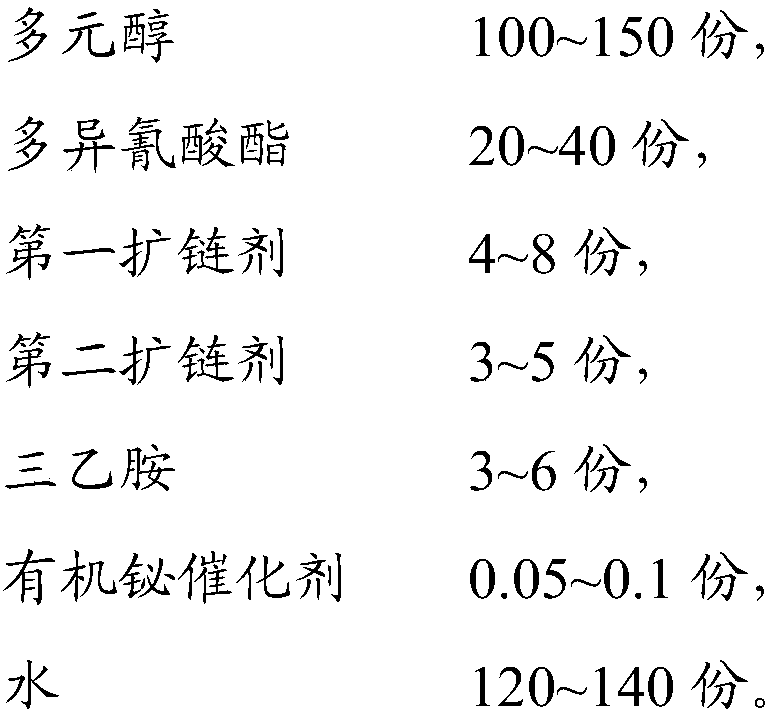

[0033] A high-solid-content water-based polyether polyurethane resin consists of the following raw materials in parts by weight:

[0034]

[0035] Weigh polysiloxane polyol and isophorone diisocyanate by parts, and react at 85-95°C for 2-3 hours; then add dimethylol propionic acid, dimethylol butyric acid, acetone, and React at 75-85°C for 1-3 hours; then add organic bismuth 1610, react at 65-75°C for 2-3 hours, cool down to 35-45°C, add triethylamine and stir, add water and continue stirring, then add iso Phortonediamine, reacting the reactant at 30-60° C. for 2-3 hours, and removing the acetone in a vacuum to obtain the high-solid-content water-based polyether polyurethane resin.

[0036] The high solid content water-based polyether polyurethane resin is thickened, moistened and defoamed, and then directly coated on the textile coating.

[0037] The high solid content water-based polyether polyurethane resin of this embodiment has a solid content of more than 60%, and is...

Embodiment 2

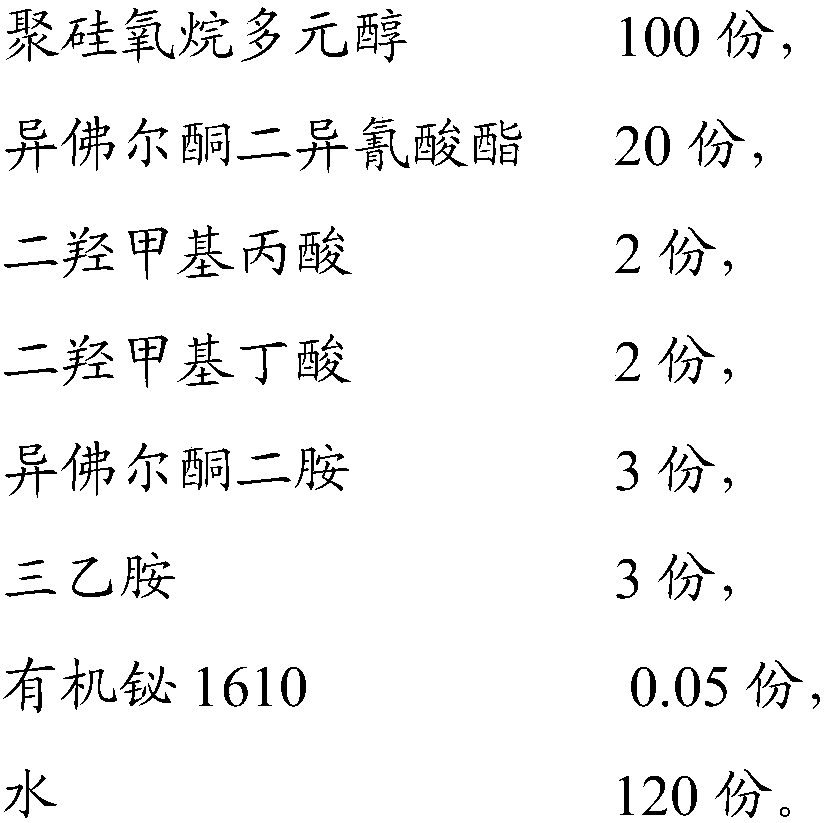

[0039] A high-solid-content water-based polyether polyurethane resin consists of the following raw materials in parts by weight:

[0040]

[0041]

[0042] Weigh hydroxyl-terminated polybutadiene and naphthalene-1,5-diisocyanate in parts, and react at 90°C for 2 to 3 hours; then add dimethylol butyric acid, dimethylol octanoic acid, acetone, and React at 80°C for 2 hours; then add organic bismuth 2010, react at 70°C for 2-3 hours, cool down to 40°C, add triethylamine and stir, add water and continue stirring, then add hexamethylenediamine, and then put the reactant in React at 50° C. for 2 to 3 hours, and remove the acetone in a vacuum to obtain the high-solid-content water-based polyether polyurethane resin.

[0043] The high solid content water-based polyether polyurethane resin is thickened, moistened and defoamed, and then directly coated on the textile coating.

[0044] The high solid content water-based polyether polyurethane resin of this embodiment has a solid c...

Embodiment 3

[0046] A high-solid-content water-based polyether polyurethane resin consists of the following raw materials in parts by weight:

[0047]

[0048] Weigh polypropylene oxide polyol and methylcyclohexyl diisocyanate in parts, and react at 95°C for 3h; then add dimethylolvaleric acid, dimethylolbutyric acid, acetone, and react at 85°C 3h; then add organic bismuth 2810, react at 75°C for 3h, cool down to 45°C, add triethylamine and stir, add water and continue stirring, then add diethylenetriamine, then react the reactant at 60°C for 3h The high solid content water-based polyether polyurethane resin can be obtained by removing the acetone in vacuum.

[0049] The high solid content water-based polyether polyurethane resin is thickened, moistened and defoamed, and then directly coated on the textile coating.

[0050] The high solid content waterborne polyether polyurethane resin of this embodiment has a solid content of 65%, which is especially suitable for textile coatings, whi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap