Spline shaft of hydraulic pump

A spline shaft and hydraulic pump technology, which is applied in the field of hydraulic pump spline shafts, can solve the problems of low hardness and non-wear resistance, and achieve the effects of reducing oxygen content, increasing strength, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

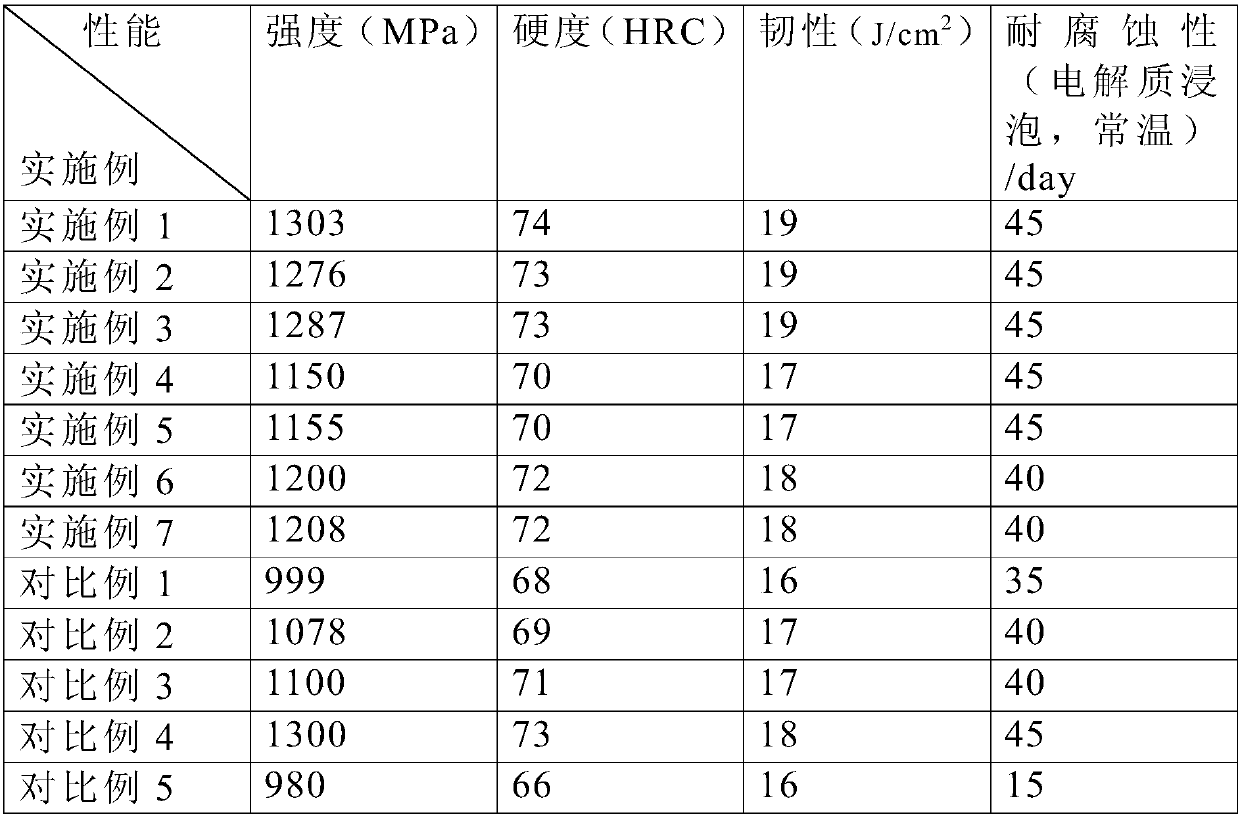

Examples

Embodiment 1

[0034] Ingredients: Weigh raw materials according to the composition and mass percentage of the above hydraulic pump spline shaft, including Si: 0.5%, Mn: 0.2%, C: 0.3%, Cr: 0.4%, Al: 0.3%, Ni: 0.3%, Mo: 0.2%, Ti: 0.08%, the balance is Fe and impurities, wherein the impurities include H<0.002%, S<0.003%, N<0.004%, O<0.001%. Fe, Cr, and Ni are directly smelted into alloy liquid 1.

[0035] Deoxygenation: first add Al and Mo to the alloy liquid 1 for pre-deoxidation, then add C, Si, Mn for secondary deoxidation, then use jet mill to grind Ti into Ti powder with a particle size of 300nm, and finally add The Ti powder is finally deoxidized to form an alloy solution 2, and the alloy solution 2 is poured into an alloy steel plate.

[0036] Steel plate rolling: heat the alloy steel plate at a heating rate of 30°C / s to 1150°C, keep it warm for 100min, cool it naturally to 1050°C, and perform the first mechanical rolling. The thickness of the steel plate is reduced from 80mm to 40mm, ...

Embodiment 2

[0039]Ingredients: Weigh raw materials according to the composition and mass percentage of the above-mentioned spline shaft of the hydraulic pump, including Si: 0.4%, Mn: 0.1%, C: 0.2%, Cr: 0.3%, Al: 0.2%, Ni: 0.2%, Mo: 0.1%, Ti: 0.05%, the balance is Fe and impurities, wherein the impurities include H<0.002%, S<0.003%, N<0.004%, O<0.001%. Fe, Cr, and Ni are directly smelted into alloy liquid 1.

[0040] Deoxygenation: first add Al and Mo to the alloy liquid 1 for pre-deoxidation, then add C, Si, Mn for secondary deoxidation, then use jet mill to grind Ti into Ti powder with a particle size of 300nm, and finally add The Ti powder is finally deoxidized to form an alloy solution 2, and the alloy solution 2 is poured into an alloy steel plate.

[0041] Steel plate rolling: heat the alloy steel plate at a heating rate of 30°C / s to 1150°C, keep it warm for 100min, cool it naturally to 1050°C, and perform the first mechanical rolling. The thickness of the steel plate is reduced fro...

Embodiment 3

[0044] Ingredients: Weigh raw materials according to the composition and mass percentage of the above-mentioned spline shaft of the hydraulic pump, including Si: 0.6%, Mn: 0.3%, C: 0.4%, Cr: 0.5%, Al: 0.4%, Ni: 0.4%, Mo: 0.3%, Ti: 0.1%, the balance is Fe and impurities, wherein the impurities include H<0.002%, S<0.003%, N<0.004%, O<0.001%. Fe, Cr, and Ni are directly smelted into alloy liquid 1.

[0045] Deoxygenation: first add Al and Mo to the alloy liquid 1 for pre-deoxidation, then add C, Si, Mn for secondary deoxidation, then use jet mill to grind Ti into Ti powder with a particle size of 300nm, and finally add The Ti powder is finally deoxidized to form an alloy solution 2, and the alloy solution 2 is poured into an alloy steel plate.

[0046] Steel plate rolling: heat the alloy steel plate at a heating rate of 30°C / s to 1150°C, keep it warm for 100min, cool it naturally to 1050°C, and perform the first mechanical rolling. The thickness of the steel plate is reduced fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com