A kind of methoxypolyethylene glycol-polymethacrylate block copolymer and its preparation method and application

A technology of methoxypolyethylene glycol and polymethacrylic acid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of high viscosity of polysurfactant, difficulty in separating polysurfactant, and restriction of polysurfactant Large-scale application and other issues to achieve the effect of improving oil washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

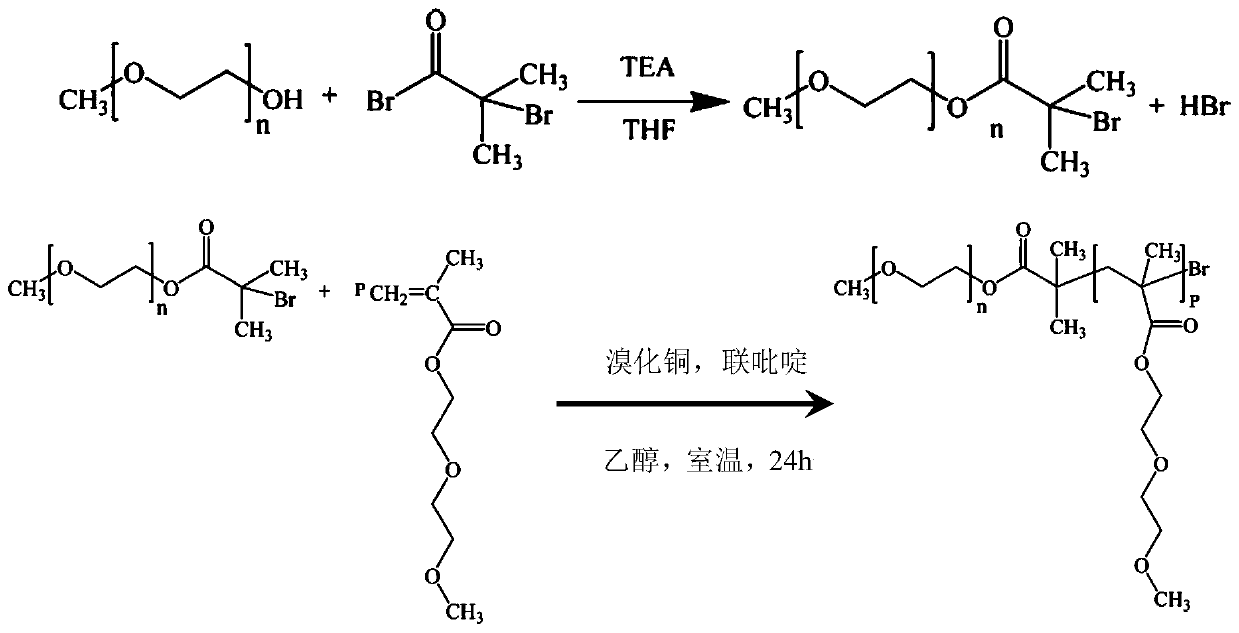

[0029] According to a second aspect of the present invention, the present invention provides a method for preparing a methoxy polyethylene glycol-polymethacrylate block copolymer, the method comprising:

[0030] 1) under the protection of an inert gas, the bromine-terminated methoxypolyethylene glycol of the structure shown in formula (2) is used as a macroinitiator, the copper halide is used as a catalyst, and bipyridine is used as a catalyst ligand, and (3) The polymerized monomer of the shown structure (2-methyl-2-acrylate-2-(2-methoxyethoxy) ethyl ester, MEO 2 MA) carrying out atom transfer radical polymerization (ATRP) in an organic solvent to obtain a reaction solution;

[0031] 2) making the reaction solution contact with an oxygen-containing gas, thereby terminating the polymerization reaction; then removing the solvent therein to obtain an oily mixture;

[0032]

[0033] Wherein, n=4-200; the molar ratio of the macroinitiator to the polymerized monomer is 1:4-200....

Embodiment 1

[0059] This example is used to illustrate the block copolymer of the present invention and its preparation method.

[0060] The reaction flow chart is as figure 1 Shown:

[0061] (1) Preparation of macroinitiator (bromine-terminated methoxypolyethylene glycol)

[0062] In a completely dry three-necked flask, 5.5 g of mPEG was dissolved in 50 mL of tetrahydrofuran (THF), and an inert gas was passed, and 0.46 mL of triethylamine was added thereto. Then, the flask was placed in ice water at 0°C, and 0.82 mL of 2-bromoisobutyryl bromide was injected into the flask through a syringe. The reaction solution was magnetically stirred at room temperature for 24 hours, and an inert gas flow was maintained throughout the reaction to avoid oxygen. entry. After the precipitate produced in the reaction was removed by centrifugation, magnesium sulfate was added to remove the moisture in the remaining solution. Then the obtained clear solution was dripped dropwise into a large amount of he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com