Silicon/graphene composite thin film electrode and preparation method thereof and lithium ion battery

A technology of graphene composite and graphene film, which is applied in the direction of electrode carrier/current collector, battery electrode, secondary battery, etc., can solve the problems of poor silicon cycle stability, detachment, uneven composite, etc., and achieve high rate performance and ratio The effect of high capacity and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

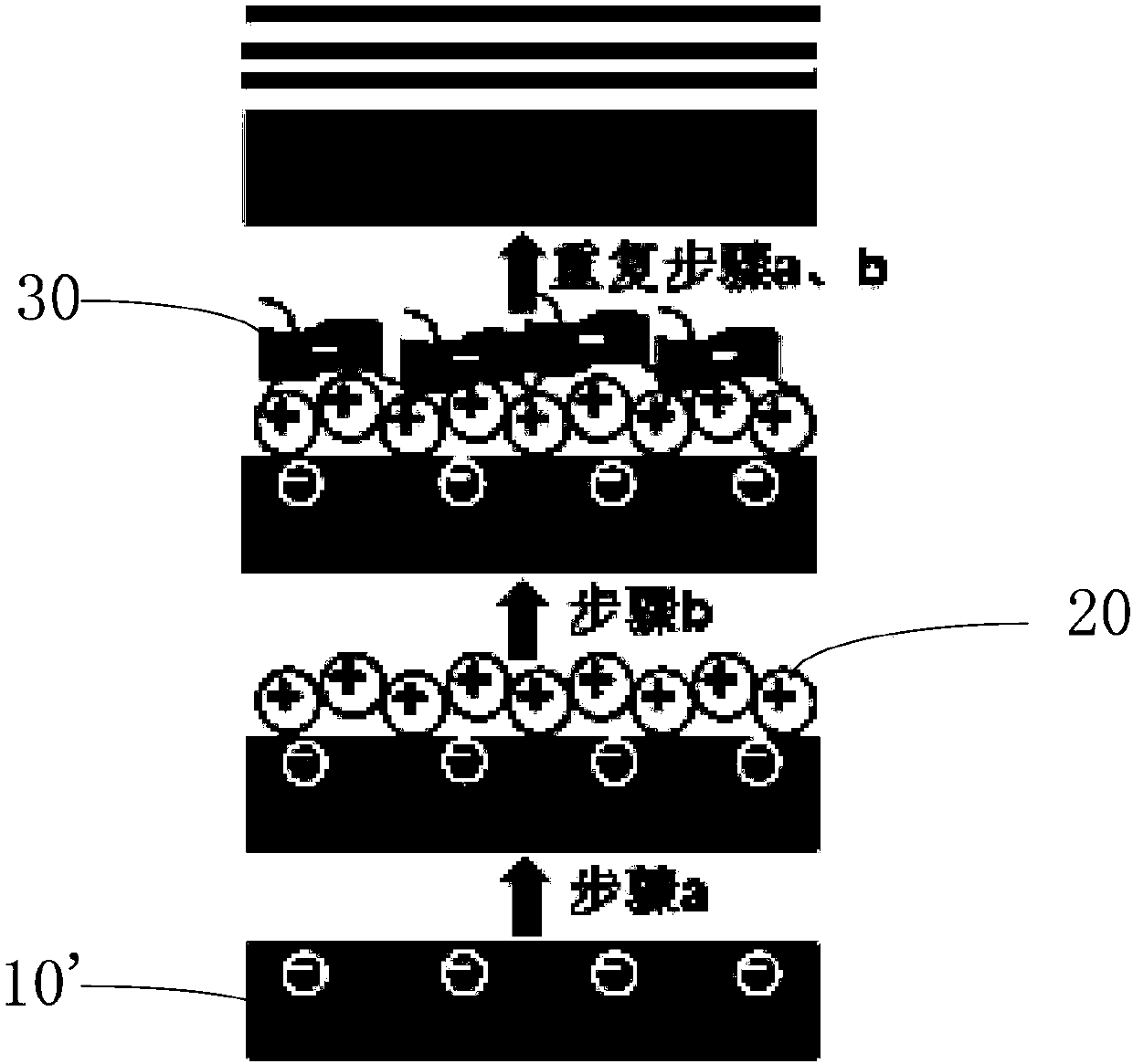

[0052] Correspondingly, an embodiment of the present invention provides a method for preparing a silicon / graphene composite thin film electrode, comprising the following steps:

[0053] S10, providing a current collector, and performing a negatively charged current collector on the current collector to obtain a negatively charged current collector;

[0054] S20, providing a silicon material, and performing charge treatment on the silicon material to obtain a charged silicon material dispersion;

[0055] S30, providing graphene, and charging the graphene to obtain a graphene dispersion with an opposite charge to the silicon material;

[0056] S40. Alternately immerse the negatively charged current collector into the charged silicon material dispersion and the graphene dispersion oppositely charged to the silicon material, and act on the negatively charged current collector through electrostatic attraction Deposit a silicon film layer and a graphene film layer, and finally self...

Embodiment 1

[0071] A method for preparing a silicon / graphene composite film electrode, comprising the following steps:

[0072] S10, negatively charge the current collector: soak the purified copper foam current collector in 2wt% Ca(OH) 2 Soak in ethanol aqueous solution (the volume ratio of ethanol and water is 1:3) for 20min, and then wash repeatedly with ultrapure water to obtain a foamed copper current collector with a negative charge on the surface;

[0073] S20, positively charge the silicon material: Weigh 100 mg of silicon nanoparticles (D50 is 200-300 nm) and co-disperse with 100 mg of PDDA in 500 mL of deionized water, ultrasonically disperse for 30 min; centrifuge the dispersion and wash it repeatedly with deionized water Precipitate, to remove excess PDDA, disperse the washed product in deionized water, and prepare 100mL positively charged Si-PDDA dispersion;

[0074] S30. Negatively charge the graphene sheets: disperse the reduced and mechanically exfoliated graphene nanoshe...

Embodiment 2

[0078] A method for preparing a silicon / graphene composite film electrode, comprising the following steps:

[0079] S10. Negatively charge the current collector: soak the purified copper foil current collector in 1 wt% KOH ethanol aqueous solution (the volume ratio of ethanol and water is 2:3) for 5 minutes, and then wash it repeatedly with ultrapure water, A copper foil current collector with a negative charge on the surface is obtained;

[0080] S20, positively charge the silicon material: Weigh 500 mg of silicon nanoparticles (D50 is 500 nm) and co-disperse with 40 mg of PDDA in 200 mL of deionized water, ultrasonically disperse for 30 min; centrifuge the dispersion and wash the precipitate repeatedly with deionized water, To remove excess PDDA, disperse the washed product in deionized water to prepare 500mL positively charged Si-PDDA dispersion;

[0081] S30. Negatively charge the graphene sheets: disperse the reduced and mechanically exfoliated graphene nanosheets in dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com