Wear-resistant material, locally reinforced light metal matrix composite material and preparation method

A technology of wear-resistant materials and composite materials, which is applied in the field of light metal matrix composites and light metal matrix composites, and can solve the problems of dimensional accuracy of castings, poor surface finish, difficult control of internal shrinkage pores, difficulty in disassembly and maintenance of parts, etc. problems, to achieve the effect of improving passing performance, improving vehicle safety, and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

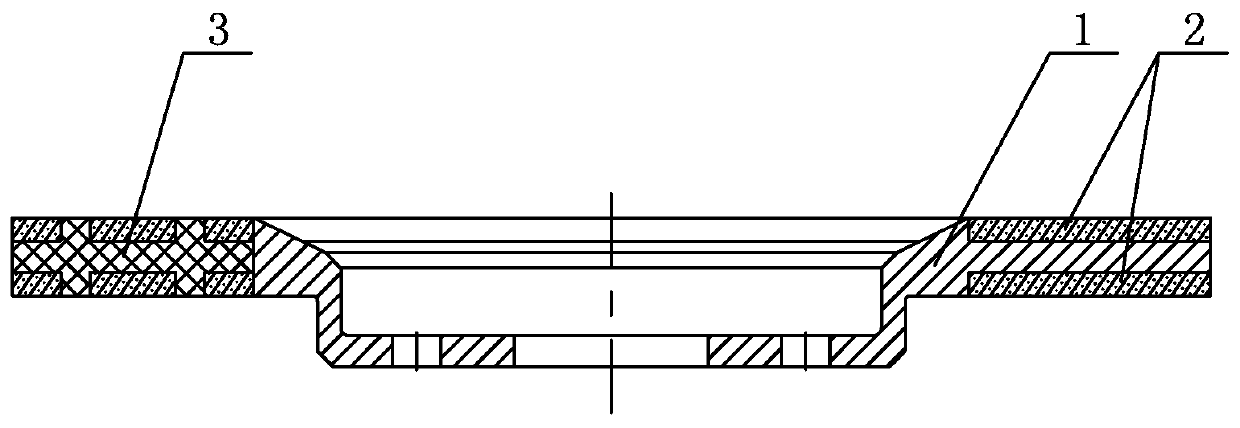

[0025] Embodiment 1: prepare the aluminum alloy automobile brake disk with wear-resistant layer, this automobile brake disk is made by the casting aluminum alloy of American brand A356, and its size is Φ288mm (outer diameter) * 44.6mm (thickness), its resistance The grinding layer is a circular ring with a size of Φ288mm (outer diameter)×184mm (inner diameter)×3mm (thickness). The preparation method comprises the following steps:

[0026] (1) Copper foam with a porosity of 10-60ppi and a thickness of 10mm is machined into Φ288mm (outer diameter) × 184mm (inner diameter) × 10mm (thickness) to obtain a high-temperature-resistant metal skeleton, and the high-temperature-resistant metal skeleton is placed in the preform mold;

[0027] (2) In terms of mass fraction, 10% alumina fiber, 5% aluminum silicate fiber, 40% fly ash particles, 8% silicon carbide particles and 3% carboxymethyl cellulose aqueous solution (concentration 20%) and 12% silica gel solution (concentration is 50%)...

Embodiment 2

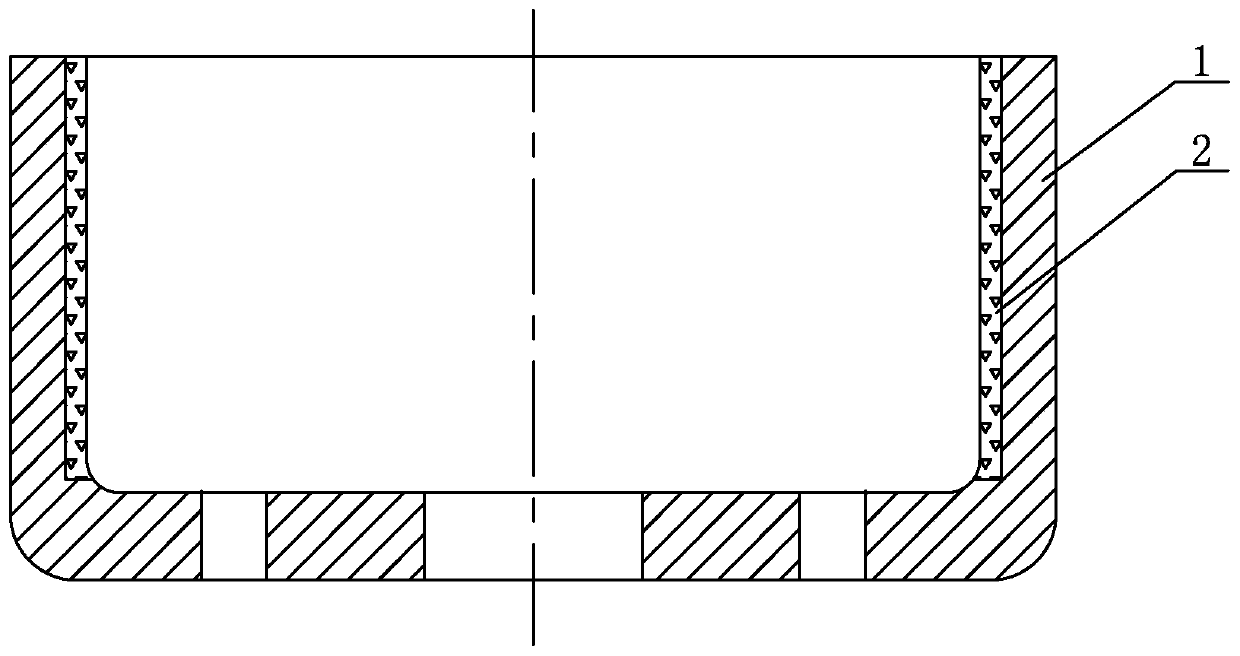

[0030] Embodiment 2: prepare the magnesium alloy truck brake hub with wear-resistant layer, this automobile brake hub is made by the casting magnesium alloy of American designation AZ91D, and its size is Φ480mm (outer diameter) * 227mm (height), and its wear-resistant The size of the layer is Φ420mm (outer diameter)×180mm (height)×7mm (tube wall thickness). The preparation method comprises the following steps:

[0031] (1) According to the mass fraction, 40% of the high-strength steel fibers with a diameter of 0.4 to 1mm are carded and woven, laid flat in the cylindrical prefabricated mold and compacted to make a high-temperature resistant metal skeleton and juxtapose In the position near the inner wall of the preform mold, 12% aluminum silicate fibers, 41% silicon carbide particles and 5% carboxymethyl cellulose aqueous solution (concentration is 20%) and 10% silicon melt solution (concentration is 60%) and proper amount of water are uniformly mixed to make a ceramic slurry,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com