Method for preparing sodium fluorosilicate by utilizing quartz sand dust

A technology of sodium fluorosilicate and quartz sand is applied in the field of preparing sodium fluorosilicate, which can solve the problems of secondary pollution of dust, and achieve the effects of improving work efficiency, large specific surface area, and avoiding floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

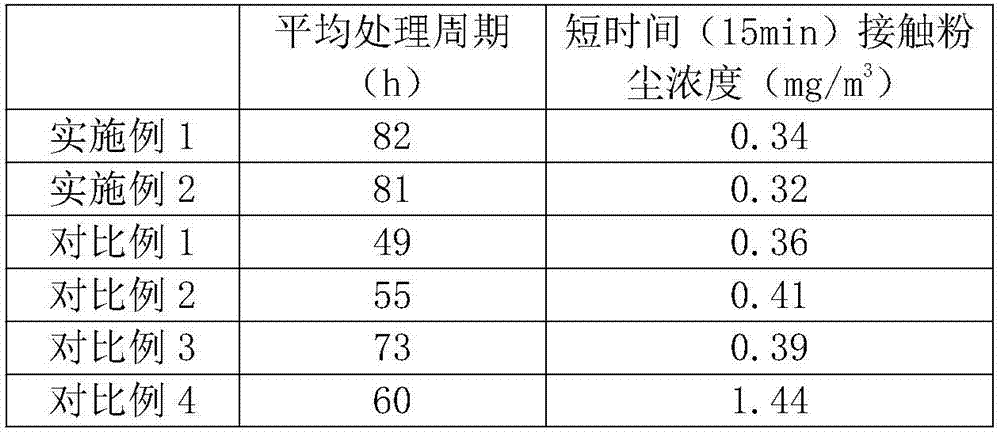

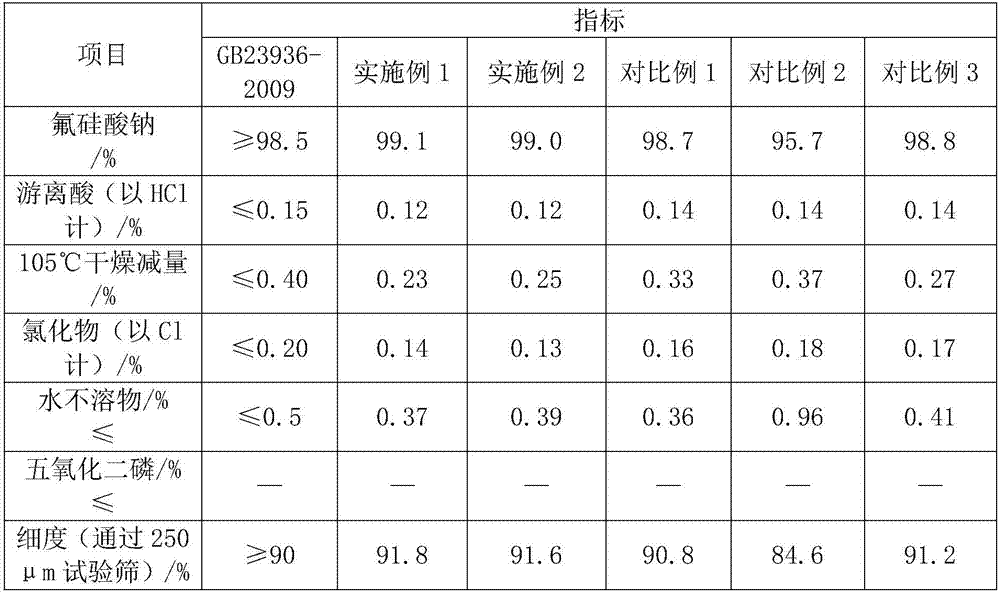

Examples

Embodiment 1

[0021] The preparation process is as follows:

[0022] (1) The quartz sand dust is collected by the filter bag filter and collected in a cuboid dust collector; the bottom wall of the dust collector is coated with a composite compound consisting of 90wt% chitosan and 10wt% silica gel microspheres. layer, the dust collector includes a feeding pipeline and an internal stirring device, and the particle size of the silica gel microspheres is 2.5-5 μm;

[0023] (2) When floating quartz sand dust appears in the dust collector, inject acidic fluorine-containing wastewater into the dust collector through the feeding pipe, wherein the fluoride ion concentration is 1750-2000mg / L, and the pH is 2-3. And turn on the agitator to generate a solution of fluorine-containing silicic acid; when the amount of fluorine-containing wastewater injected reaches 1 / 5 of the volume of the dust collector, stop the injection and turn off the agitator;

[0024] (3) Inject the acetic acid suspension solutio...

Embodiment 2

[0028] The preparation process is as follows:

[0029] The cuboid dust collector used in step (1) in Example 1 was replaced with a cylindrical dust collector of the same volume, and the rest of the preparation method was the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com