Preparation method of Sn mono-atom modified NiO nanometer material for formaldehyde sensor as well as product and application thereof

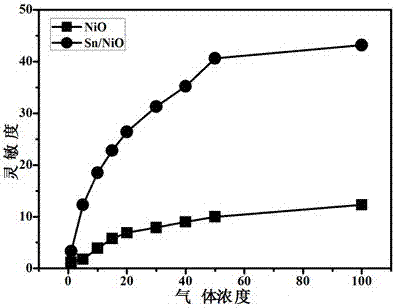

A formaldehyde sensor and nanomaterial technology, which is applied in the field of single-atom modification to improve the gas-sensing performance of p-type semiconductor nanomaterials, can solve the problems of long response time and poor sensitivity, and achieves low preparation cost, simple preparation process, and improved gas sensitivity. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

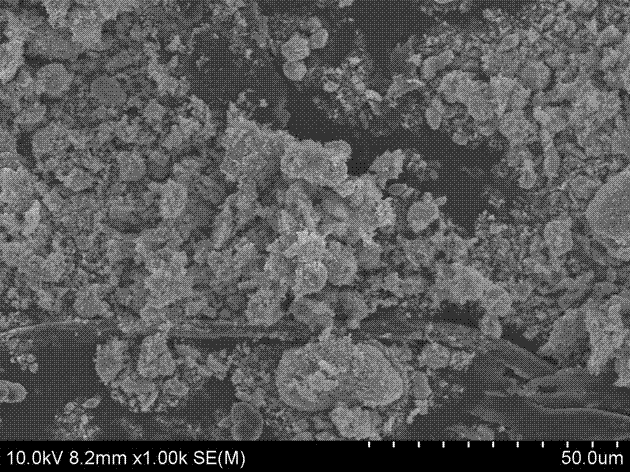

Embodiment 1

[0022] Take 0.8mmol of Ni(NO 3 ) 2 ·6H 2 O, be dissolved in the mixed solution of 13mL deionized water and 87mL ethylene glycol, obtain solution A;

[0023] Premix 4 mmol of 2-methylimidazole with 40 mL of methanol and stir until 2-methylimidazole is completely dissolved; add 3.2 mmol of ammonium bicarbonate to obtain solution B;

[0024] Mix solution A and solution B, move the solution to a water bath at 50 °C, then stir for 2-5 h, then place it in a reaction kettle, react at 150 °C for 12 h, wait until the temperature drops to room temperature, centrifuge the sample, and use After repeated washing with deionized water and absolute ethanol for 3 times, the sample was dried in a drying oven to obtain a powder;

[0025] Take 10mL of ethanol and 10mL of ethylene glycol, add 1 drop of nitric acid, reduce the temperature of the solvent to zero, and then add 0.1mmol of anhydrous SnCl 4 After stirring for 10 min, 0.1 g of the above powder was added, placed in a muffle furnace, a...

Embodiment 2

[0028] Take 0.8mmol of Ni(NO 3 ) 2 ·6H 2 O, be dissolved in the mixed solution of 13mL deionized water and 87mL ethylene glycol, obtain solution A;

[0029] Premix 4 mmol of 2-methylimidazole with 40 mL of methanol and stir until 2-methylimidazole is completely dissolved; add 3.2 mmol of ammonium bicarbonate to obtain solution B;

[0030] Mix solution A and solution B, move the solution to a water bath at 50 °C, then stir for 2-5 h, then place it in a reaction kettle, react at 150 °C for 12 h, wait until the temperature drops to room temperature, centrifuge the sample, and use After repeated washing with deionized water and absolute ethanol for 3 times, the sample was dried in a drying oven to obtain NiO powder for later use;

[0031] Take 10mL of ethanol and 10mL of ethylene glycol, add 1 drop of nitric acid, reduce the temperature of the solvent to zero, and then add 0.1mmol of anhydrous SnCl 4 After stirring for 10 minutes, add 0.1g of NiO powder, stir for 30 minutes, p...

Embodiment 3

[0035] Take 0.5mmol of nickel chloride and dissolve it in a mixed solution of 10mL deionized water and 90mL ethylene glycol to obtain solution A;

[0036] Premix 4mmol of 1-methylimidazole with 20mL of methanol, stir until 1-methylimidazole is completely dissolved; add 1.5mmol of ammonium bicarbonate to obtain solution B;

[0037] Mix solution A and solution B, move the solution to a water bath at 30 °C, then stir for 2 h, then place it in a reaction kettle, react at 140 °C for 14 h, wait until the temperature drops to room temperature, centrifuge the sample, and use deionized After repeated washing with water and absolute ethanol twice, the sample was dried in a drying oven to obtain Ni(OH) 2 powder spare;

[0038] Take 16mL of ethanol and 4mL of ethylene glycol premixed, add 2 drops of nitric acid, reduce the temperature of the solvent to zero, and then add 0.2mmol of anhydrous SnCl 4 , after stirring for 20min, add 0.1g of Ni(OH) 2 The powder was stirred for 30 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com