Sludge resource utilization device and method thereof

A technology for resource utilization and sludge, applied in chemical instruments and methods, combustion methods, combined devices, etc., can solve the problems of lack of flue gas denitrification technology, and achieve the effects of saving coal consumption, high efficiency and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below.

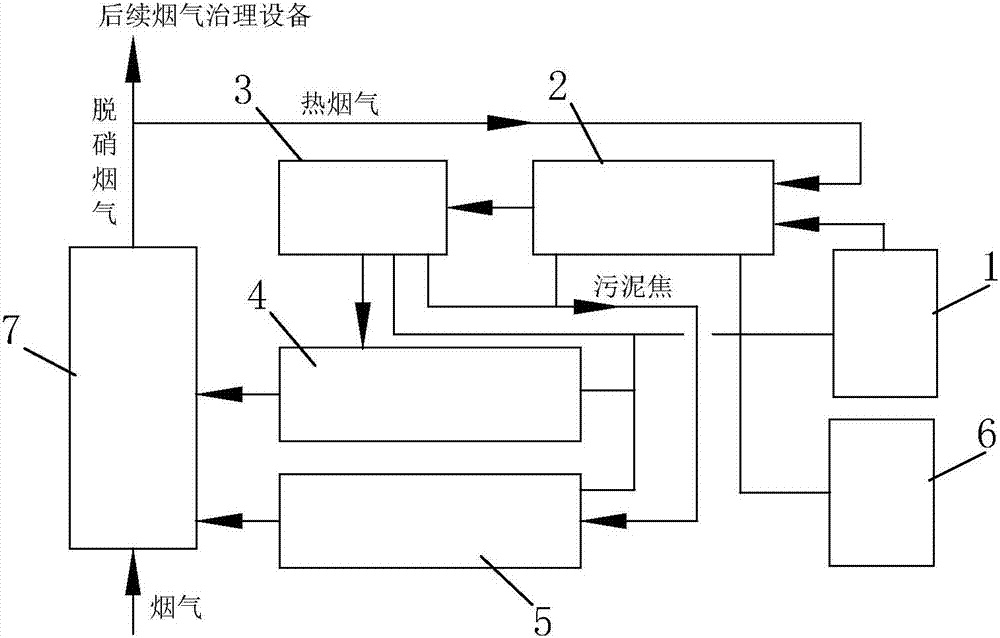

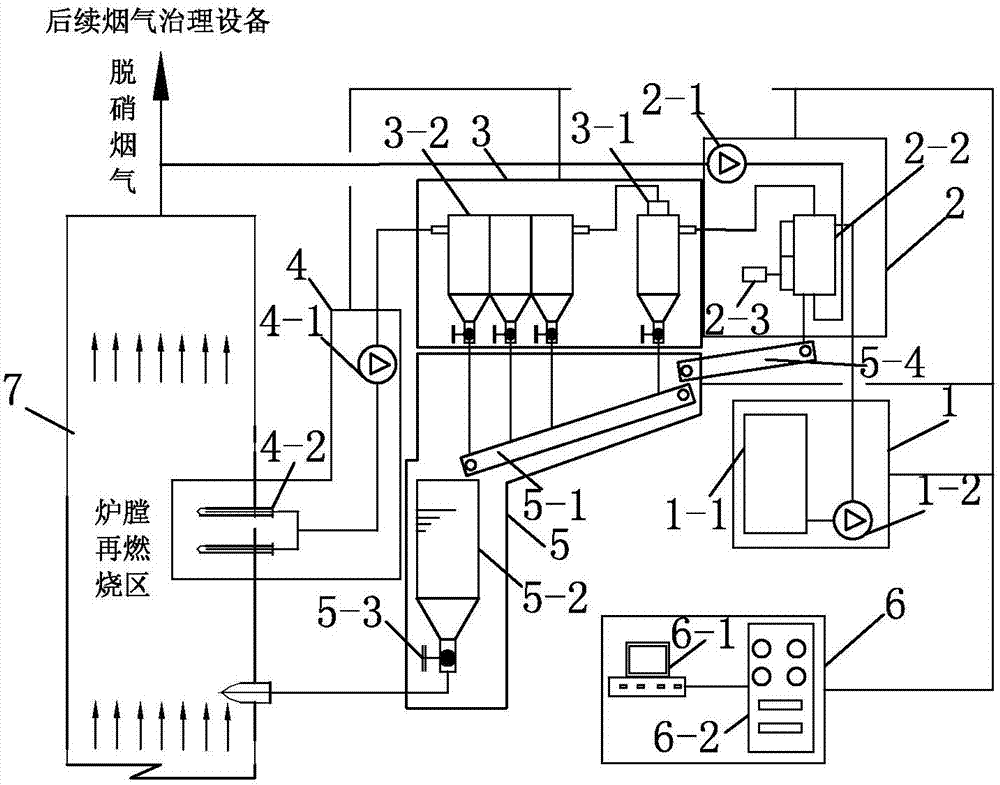

[0034] A sludge resource utilization device, including a sludge storage and transportation unit 1, a pyrolysis reaction unit 2, a dust removal unit 3, a pyrolysis gas injection unit 4, an industrial boiler 7, a sludge coke collection and addition unit 5, and an automatic control unit Unit 6, the automatic control unit 6 controls the above-mentioned units to work. In addition to the industrial boiler 7, the device and method of the present application are also suitable for industrial kilns, and here only the industrial boiler 7 is used as a specific example. The sludge storage and delivery unit 1, the pyrolysis reaction unit 2, the dust removal unit 3, the pyrolysis gas injection unit 4, and the industrial boiler 7 are connected in sequence, and a sludge delivery pipe is provided between the sludge storage and delivery unit 1 and the pyrolysis reaction unit 2, A first pyrolysis gas delivery pipe is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com