Siloxane bridged silane terminated siloxane bridged ladder like polysiloxane and preparation method thereof

A technology of siloxane bridge and polysiloxane is applied in the field of siloxane bridge ladder polysiloxane, which can solve the problems of high price, difficult to complete end capping, difficult practical application and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0113]Preferably, the preparation method of the siloxane bridging silane-terminated siloxane bridging ladder polysiloxane of the present embodiment comprises the following steps: combining structural formulas (2), (3) and (4) silanes (that is, four Functional I-shaped siloxane bridging siloxane monomer and bifunctional I-shaped siloxane bridging silane capping agent) are co-hydrolyzed in the presence of solvents, catalysts, and water, relying on supramolecular weak bond interactions (including π-π superposition, electron donor and acceptor, electrostatic, hydrophilic and hydrophobic, and hydrogen bond interactions) form a trapezoidal superstructure to regulate the polymerization and capping reaction of hydrolyzate to obtain siloxane bridging silane-capped siloxane Alkyl Bridged Ladder Polysiloxane. The preparation method comprises the following steps:

[0114] Add structural formula (2) (3) and (4) silane, solvent, water and catalyst to the reactor in a dropwise or "one-pot c...

Embodiment 1

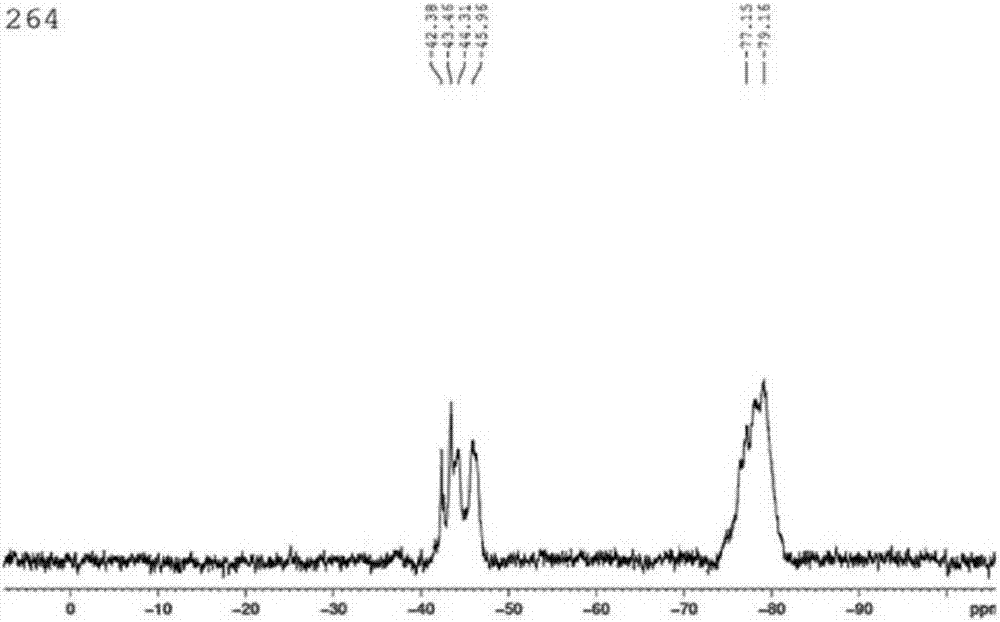

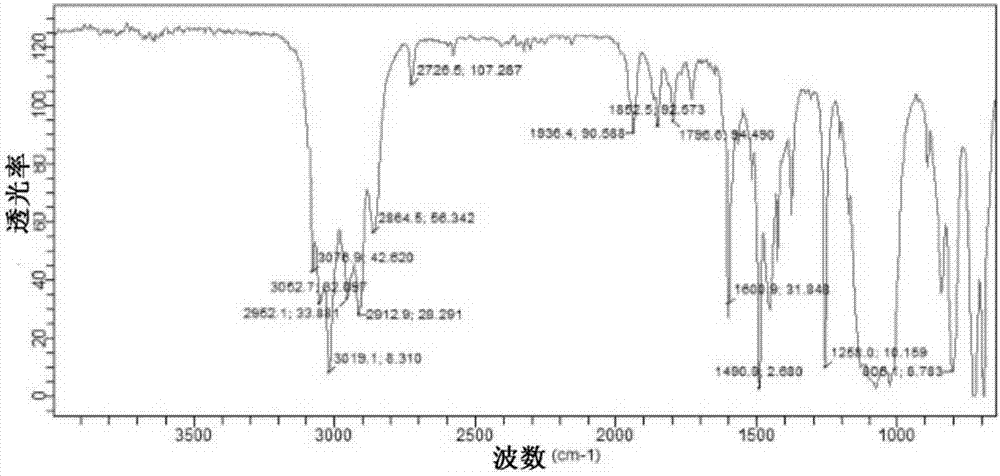

[0155] Example 1: Ph 2 -I-Ph-SLPS synthesis

[0156] A siloxane bridging silane terminated siloxane bridging ladder polysiloxane was prepared from phenyltrimethoxysilane, diphenyldimethoxysilane and diphenylsilanediol.

[0157] Under the protection of dry nitrogen, 39.6 grams of phenyltrimethoxysilane (0.20mol), 21.6 grams of diphenylsilanediol (0.01mol) and 15 grams of ethyl acetate were placed in a constant pressure dropping funnel equipped with mechanical stirring and a three-necked flask with a reflux condenser, stirred evenly at room temperature, added 0.02 g of triethanolamine at 0°C, and reacted for 8 hours to obtain intermediate 1; at the same time, in another protected by dry nitrogen, equipped with mechanical stirring, constant pressure drop Add 41.9 grams of diphenyldimethoxysilane (0.17mol), 10 grams of ethyl acetate, and 18.6 grams of diphenylsilanediol (0.09mol) into the three-necked flask of the funnel and the reflux condenser, and stir evenly. Add 0.04 g of t...

Embodiment 2

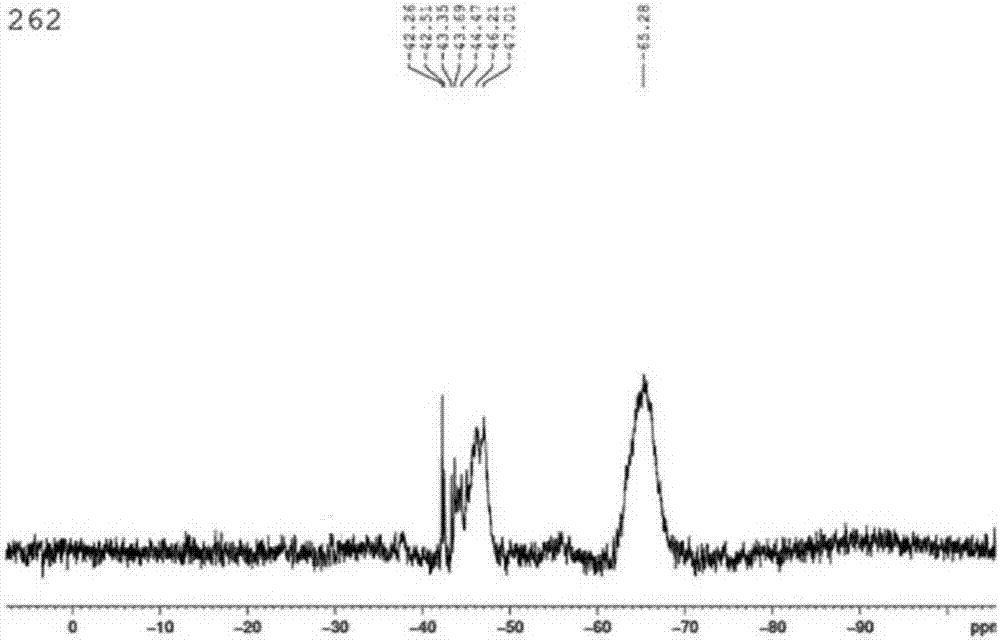

[0159] Embodiment 2: Synthesis of PhMe-I-Ph-SLPS

[0160] A siloxane bridging silane terminated siloxane bridging ladder polysiloxane was prepared from phenyltrimethoxysilane, methylphenyldimethoxysilane and diphenylsilanediol.

[0161] Under the protection of dry nitrogen, 39.6 grams of phenyltrimethoxysilane (0.20mol), 21.6 grams of diphenylsilanediol (0.10mol) and 10 grams of N,N-dimethylacetamide were placed in a mechanically stirred , a constant pressure dropping funnel and a three-necked flask with a reflux condenser, stir evenly at room temperature, add 0.10 g of liquid ammonia at -5°C, and react for 12 hours to obtain Intermediate 1; Add 3.65 grams of methylphenyldimethoxysilane (0.02mol), 10 grams of N,N-dimethylacetamide, 2.16 grams of diphenylsilane into the three-necked flask with stirring, constant pressure dropping funnel and reflux condenser Diol (0.01mol) was stirred evenly, and 0.02 gram of liquid ammonia was added at 0° C., and reacted for 18 hours to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com