Wheat bran cellulose/wheat gluten protein compound film and preparing method thereof

A technology of wheat bran and cellulose, which is applied in the field of film preparation and food packaging materials, can solve the problems of environmental pollution, high production cost, white pollution, etc., and achieve the effects of improved mechanical properties, uniform distribution, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

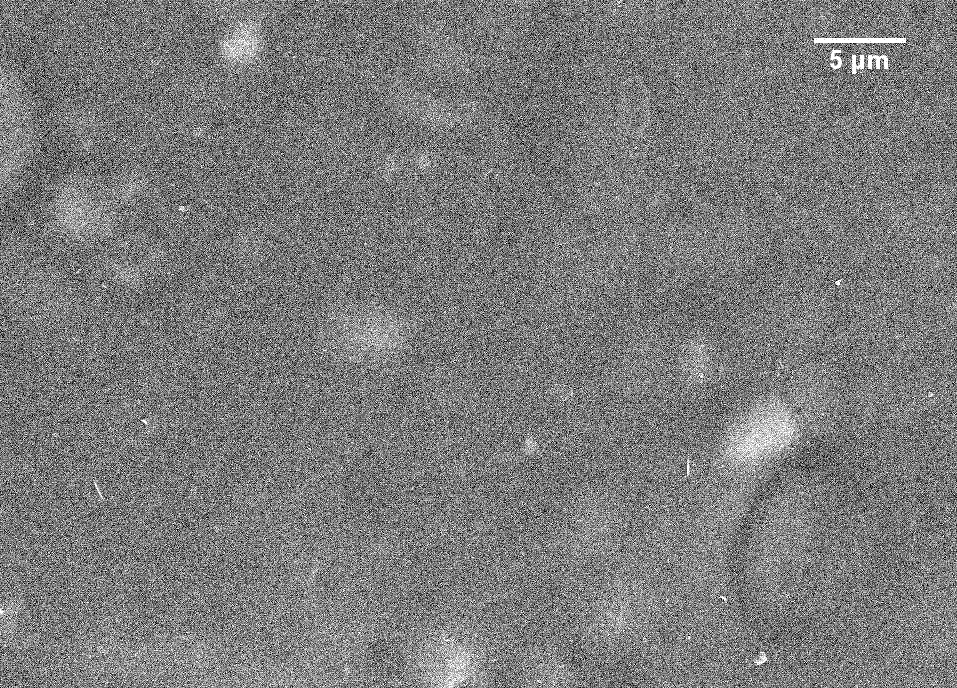

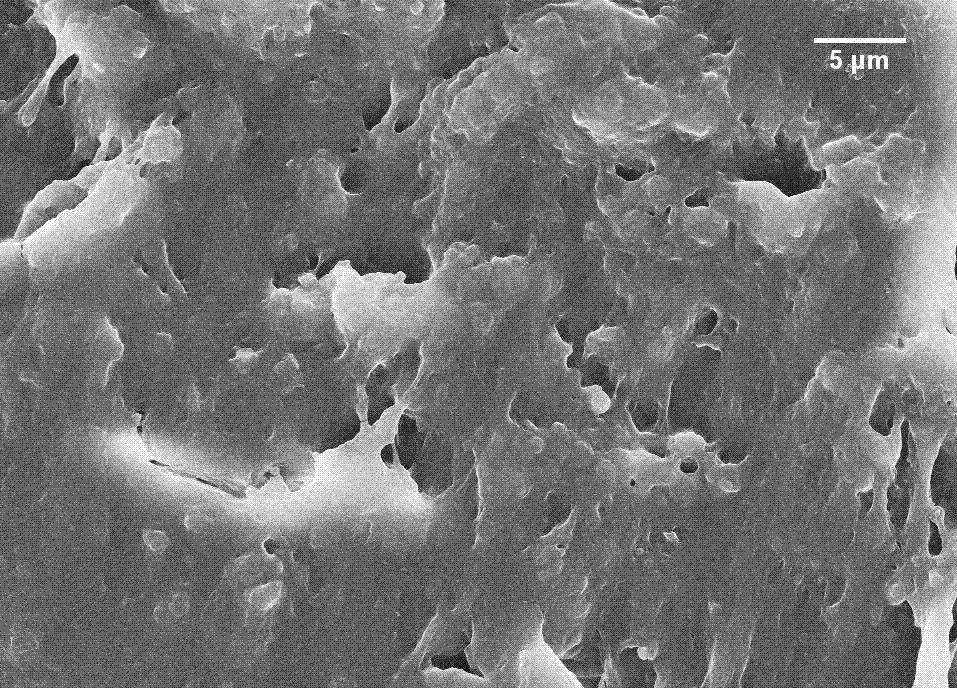

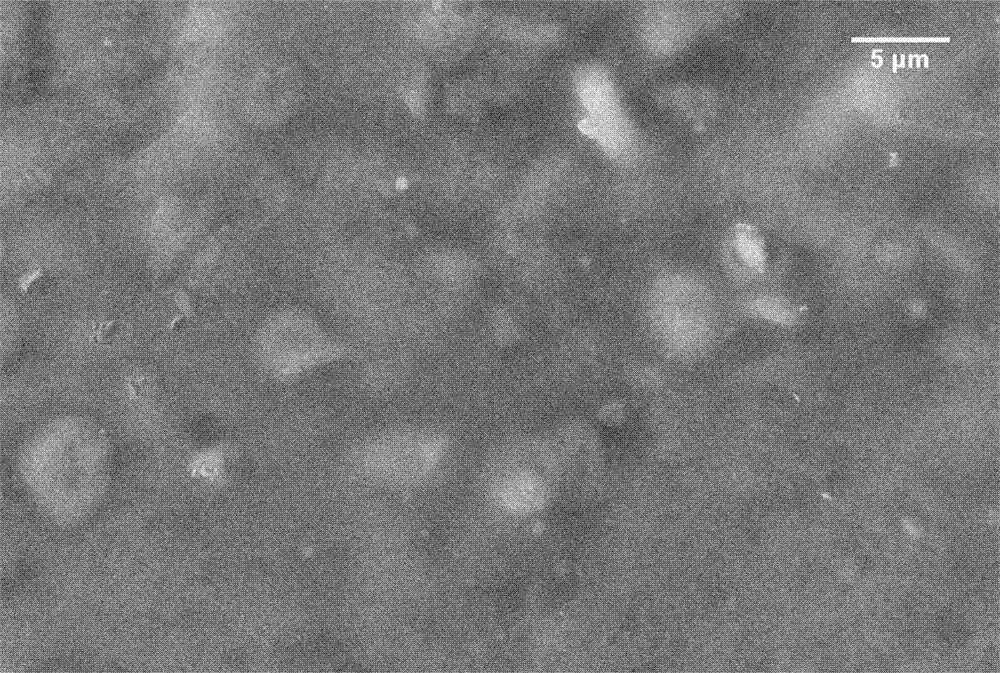

Image

Examples

Embodiment 1

[0057] The preparation method of the wheat gluten protein / wheat bran fiber composite film in this example is as follows.

[0058] (1) Weigh 500g of washed and dried wheat bran mixed with 5L of distilled water, boil for 10min, adjust the pH value to 12-13 with 2mol / L sodium hydroxide solution, and then place it in an 80°C water bath for leaching for 4- After 5 hours, centrifuge to obtain a precipitate, which is washed three times with water. Add 2mol / L hydrochloric acid to the washed precipitate, adjust its pH value to 1-2, then place it in a water bath at 60°C for 2-3 hours, filter it with filter cloth while it is hot, and wash the filter residue with water until neutral. Then, the washed filter residue is dehydrated with 75% ethanol solution, dried at 50-55 DEG C, ultrafinely pulverized to obtain wheat bran cellulose, and passed through a 120-mesh sieve for future use.

[0059] (2) Take 24g of wheat gluten protein and dissolve it in 144mL of 30% volume fraction hot ethanol s...

Embodiment 2

[0065] (1) Dissolve 32 g of wheat gluten protein in 192 mL of 20% volume fraction hot ethanol solution, adjust the pH value to 11 with 2 mol / L NaOH and 1 mol / L HCl, and then heat it in a water bath at 80°C for 15 min. Modified to obtain protein film solution. The obtained protein film solution was kept warm in a water bath at 40-45°C, and set aside.

[0066](2) Take 8 g of wheat bran cellulose obtained in the first step in Example 1, dissolve it in 166 mL of distilled water, and use a high-speed disperser to disperse at 10,000 r / min for 5 minutes at a high speed to obtain a dispersed wheat bran fiber liquid. Then, under constant stirring, slowly add the dispersed wheat bran fiber solution into the protein film solution prepared in step 2, and measure 42mL of absolute ethanol to make up the ethanol solution to the same volume fraction as step 2, and again use 2mol / L of NaOH and 1 mol / L of HCl were used to adjust the pH value to 11, and then 6 g of plasticizer glycerin and 0.0...

Embodiment 3

[0071] (1) Take 20 g of wheat gluten protein and dissolve it in 120 mL of 40% volume fraction hot ethanol solution, adjust the pH value to 10 with 2 mol / L NaOH and 1 mol / L HCl, then put it into a 85°C water bath and heat it for 15 min for heating Modified to obtain protein film solution. The obtained protein film solution was kept warm in a water bath at 40-45°C, and set aside.

[0072] (2) Take 20 g of wheat bran cellulose obtained in the first step in Example 1, dissolve it in 168 mL of distilled water, and disperse at 10,000 r / min for 5 minutes at high speed with a high-speed disperser to obtain a dispersed wheat bran fiber liquid. Then, under continuous stirring, slowly add the dispersed wheat bran fiber liquid into the protein film liquid prepared in step 2, and measure 112mL of absolute ethanol to make up the ethanol liquid to the same volume fraction as in step 2, and again use 2mol / L of NaOH and 1 mol / L of HCl were used to adjust the pH value to 10, and then 8 g of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com