Garnet-form aluminosilicate fluorescent powder, preparation method thereof and light-emitting device including same

A garnet type, aluminosilicate technology, applied in the direction of luminescent materials, semiconductor devices, chemical instruments and methods, etc., can solve the problems of low quantum efficiency of phosphor powder, low quantum efficiency, high color temperature of white light, etc., and achieve excellent thermal quenching The effects of extinction performance, improved color rendering index, and high quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

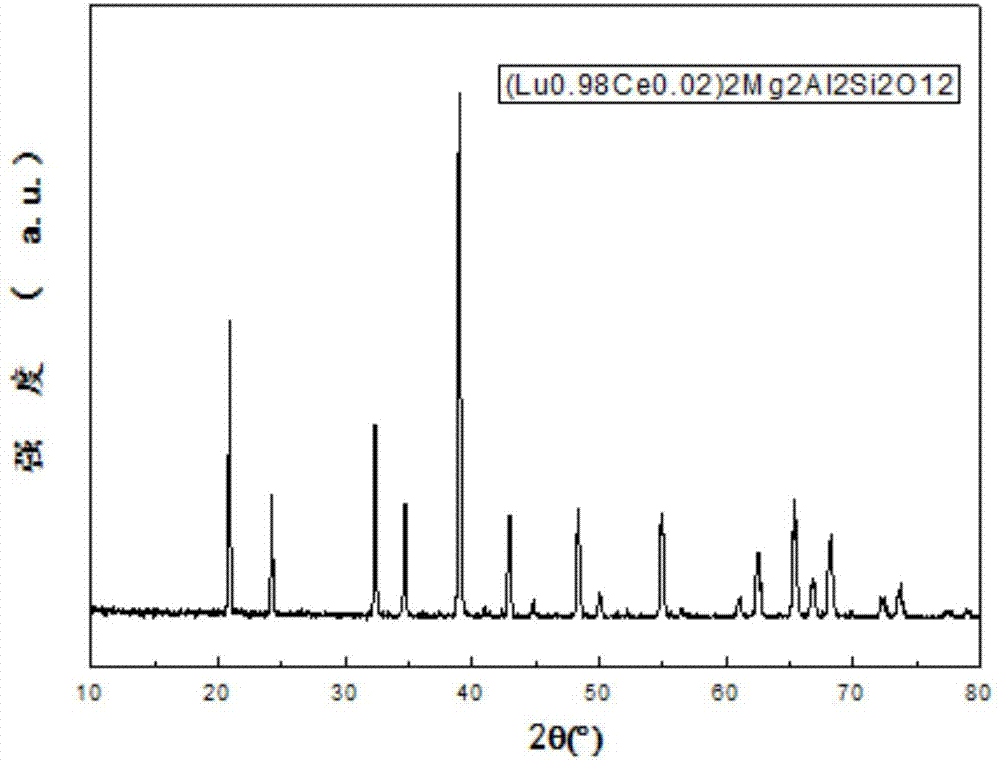

[0043] Embodiment 1: (Lu 0.98 Ce 0.02 ) 2 Mg 2 al 2 Si 2 o 12 Phosphor powder preparation

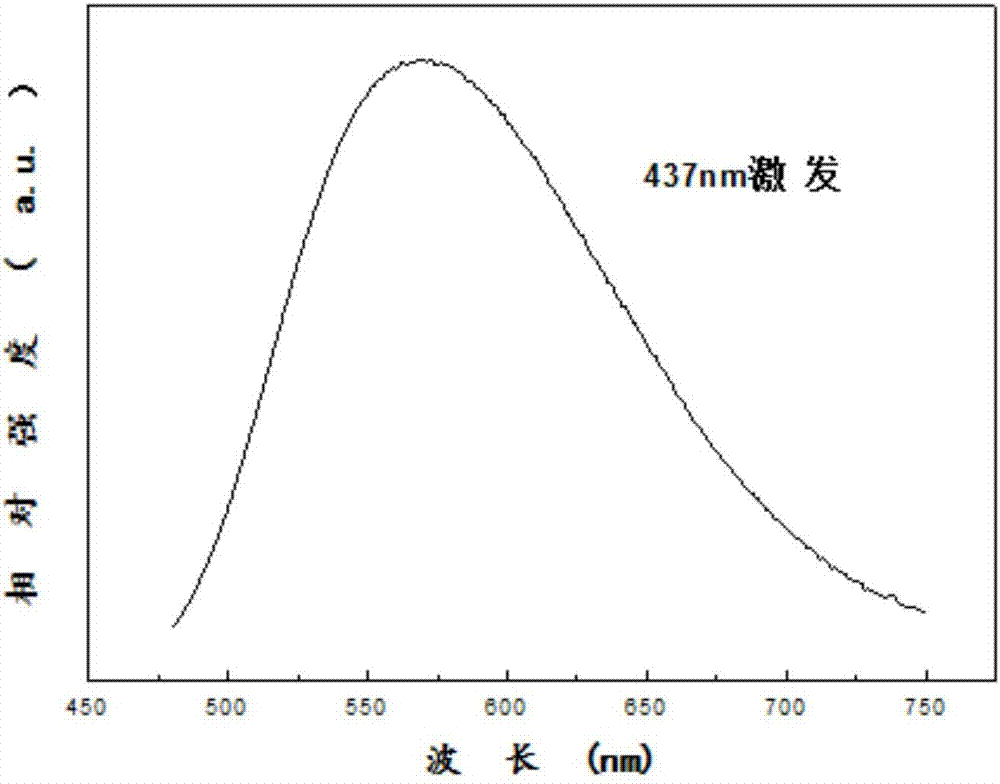

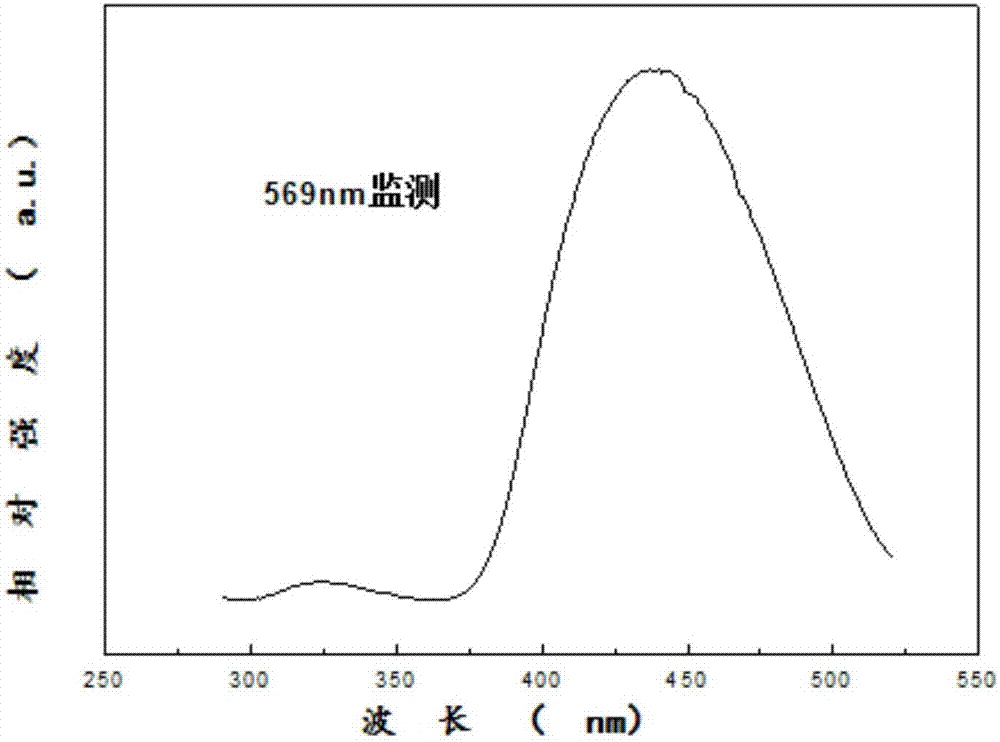

[0044] Weigh the raw material Lu according to the stoichiometric ratio 2 o 3 8.3602g, MgO1.7285g, Al 2 o 3 2.1865g, SiO 2 2.5772g, CeO 2 0.1476g, after the above-mentioned raw materials are thoroughly ground with an agate mortar, put into an alumina crucible, roast under a CO reducing atmosphere, and the roasting temperature is 1450 ° C for 2 hours. After natural cooling, post-processing such as crushing, ball milling, sieving, washing, drying, etc., can obtain phosphors of corresponding composition. The excitation spectrum wavelength coverage range is 310-520nm, the emission spectrum wavelength coverage range is 480-750nm, and the emission peak wavelength is 569nm.

Embodiment 2

[0045] Embodiment 2: (Lu 0.81 Gd 0.15 Ce 0.04 ) 2 Mg 2 al 1.9 Si 2.1 o 12.05 Phosphor powder preparation

[0046] Weigh the raw material Lu according to the stoichiometric ratio 2 o 3 6.9643g, Gd 2 o 3 1.1749g, MgO1.7421g, Al 2 o 3 2.0936g, SiO 2 2.7274g, CeO 2 0.2976g, after the above-mentioned raw materials are fully ground with agate mortar, put into alumina crucible, in N 2 / H 2 Calcining under reducing atmosphere, the calcining temperature is 1350 DEG C for 8 hours. After natural cooling, post-processing such as crushing, ball milling, sieving, washing, drying, etc., can obtain phosphors of corresponding composition. The excitation spectrum wavelength coverage range is 310-520nm, the emission spectrum wavelength coverage range is 480-750nm, and the emission peak wavelength is 585nm.

Embodiment 3

[0047] Embodiment 3: (Lu 0.91 La 0.08 Ce 0.01 ) 1.8 Mg 2.1 al 2.2 Si 2 o 12.1 Phosphor powder preparation

[0048] Weigh the raw material Lu according to the stoichiometric ratio 2 o 3 7. 3020g, La 2 o 3 0.5246g, MgO1.8968g, Al 2 o 3 2.5137g, SiO 2 2.6935g, CeO 2 0.0694g, after fully grinding the above raw materials with an agate mortar, put them into an alumina crucible, roast them in a CO reducing atmosphere, roast twice, the first time at a temperature of 1400°C for 2 hours; after natural cooling, crush Carry out the second roasting after grinding, keep the temperature at 1350°C for 7 hours. After natural cooling, post-processing such as crushing, ball milling, sieving, washing, drying, etc., can obtain phosphors of corresponding composition. The wavelength coverage range of the excitation spectrum is 310-520nm, the wavelength coverage range of the emission spectrum is 480-750nm, and the main emission peak is 573nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com