Production method of a sludge biomass mixed fuel

A production method and mixed fuel technology, applied to biofuels, waste fuels, fuels, etc., can solve the problems of high energy consumption for drying, non-uniform fuel properties, unfavorable mixing, etc., to reduce SO2 emissions, reduce types and consumption , Improve the effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

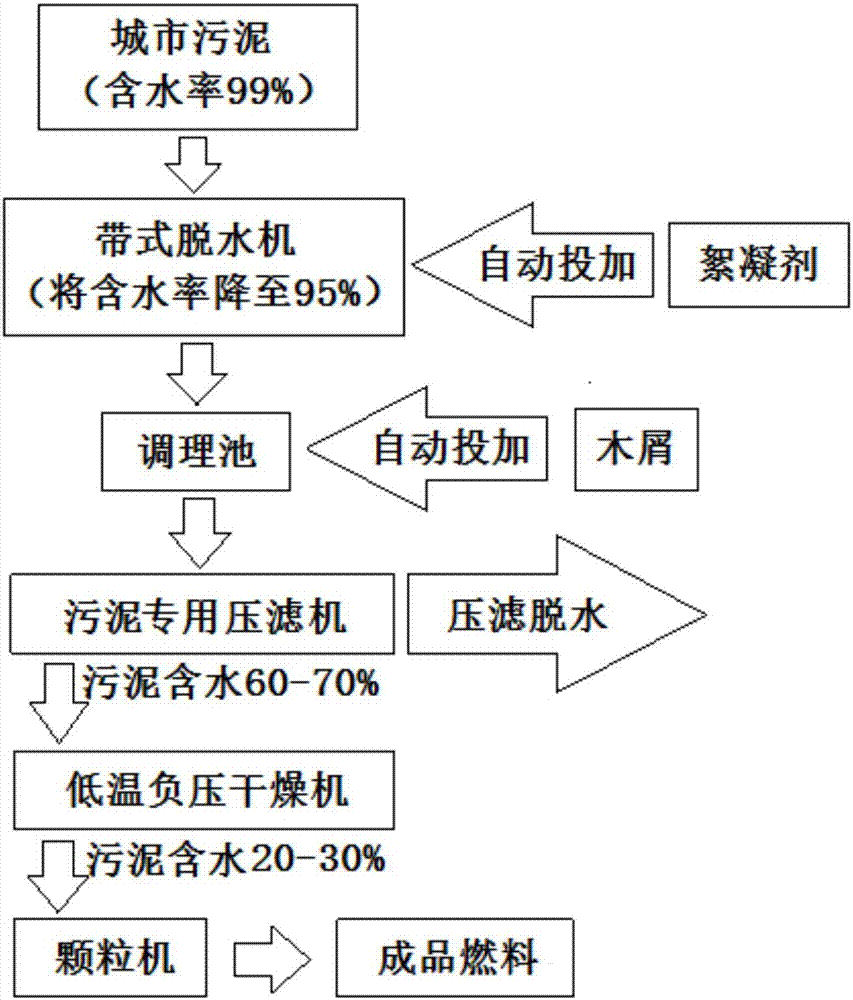

[0060] Embodiment 1: a kind of production method of sludge biomass mixed fuel, comprises the following steps:

[0061] (1) 45 tons of urban sludge with a water content of 97.35% in the sewage treatment plant is transported into the belt dehydrator by a screw pump, and at the same time, a flocculant is added quantitatively to reduce the water content of the urban sludge to about 96.22%. After 4 hours of concentration, it is obtained 31.7 tons of sludge;

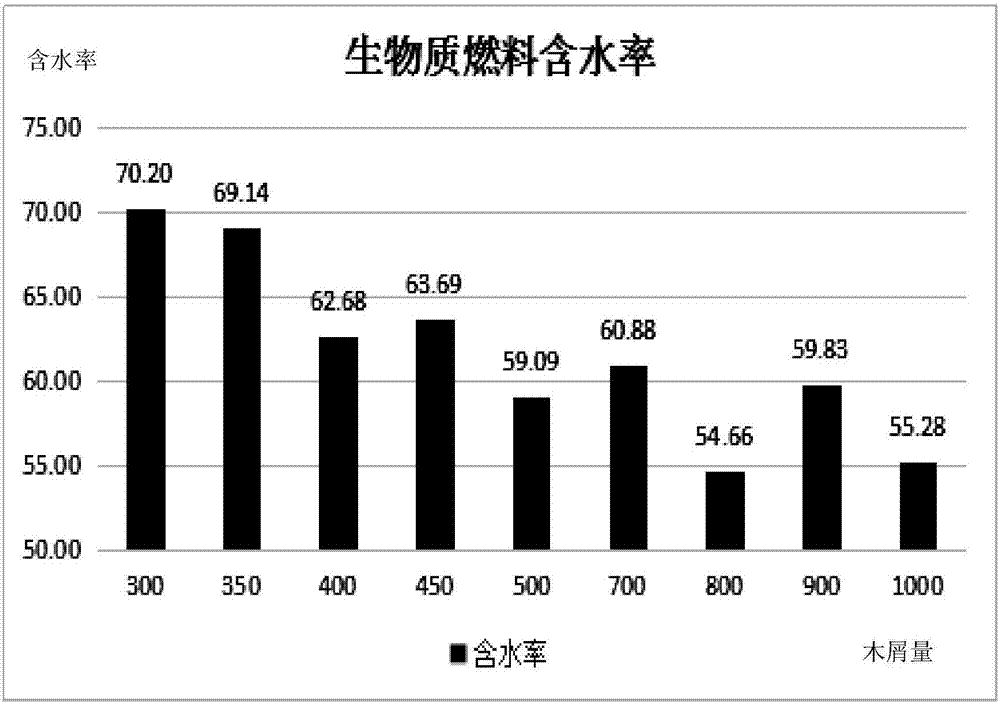

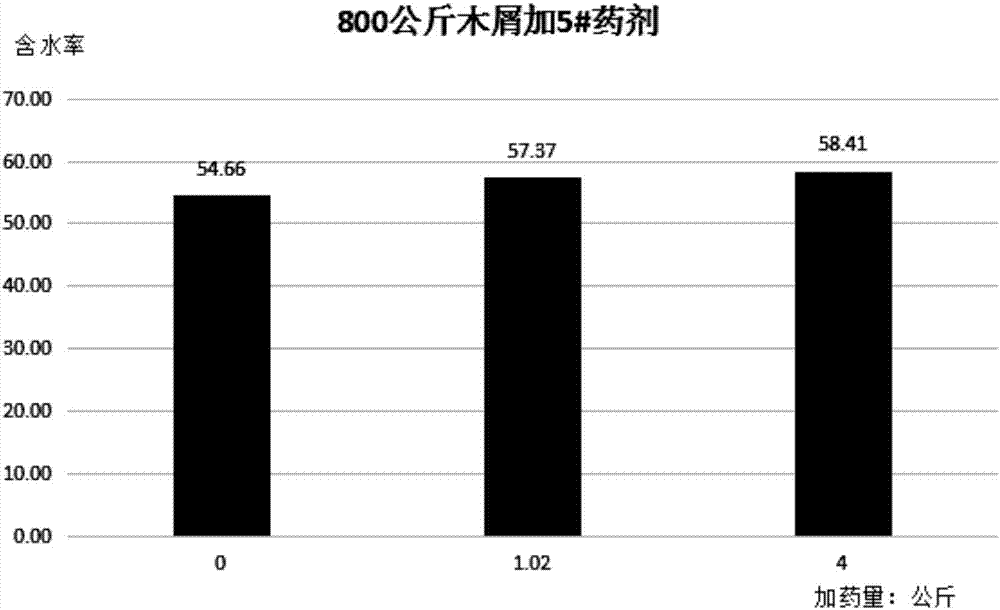

[0062] (2) 31.7 tons of urban sludge with a moisture content of 96.22% is transported into the conditioning tank of the treatment system through a screw pump, and at the same time, the mixer is turned on for stirring, and then wood chips are automatically added according to the proportion for stirring and mixing;

[0063] (3) Continue to stir for 10 minutes after the sawdust is added, and then use a high-pressure plunger pump to transport the uniformly mixed urban sludge and sawdust into a plate-and-frame filter press, which i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com