A kind of direct spinning preparation method of bright ultra-high strength polyester high tenacity polyester staple fiber

A high-toughness, light polyester technology, applied in the direction of fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of increasing energy consumption, increasing production costs, orifice expansion, etc., to increase fiber strength and reduce production Cost, improve the effect of compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

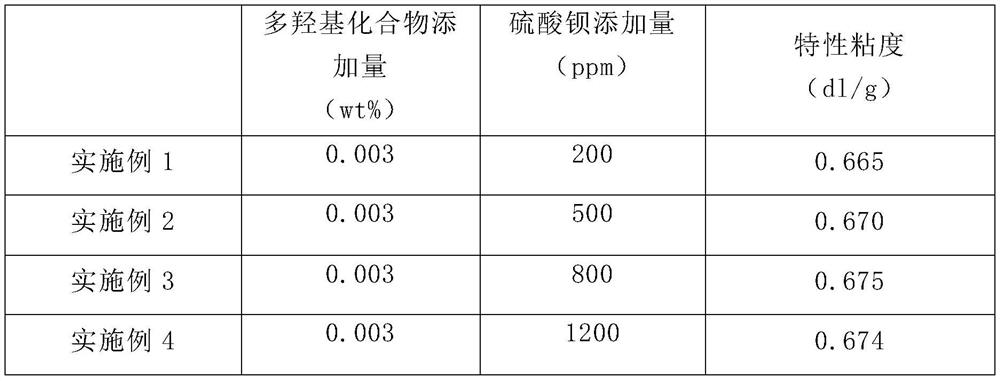

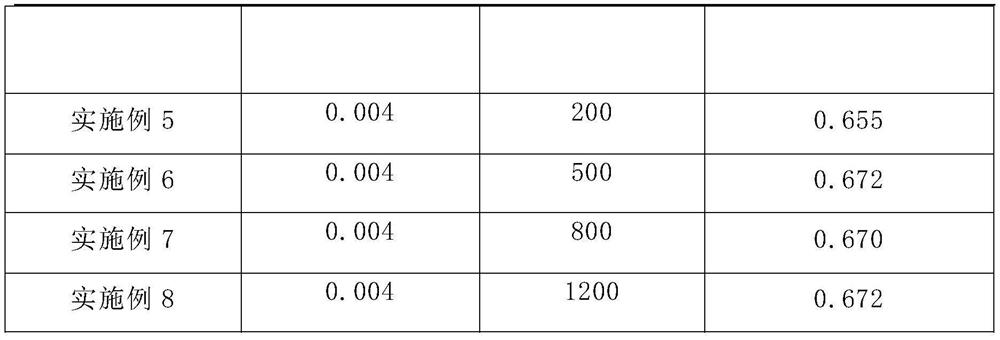

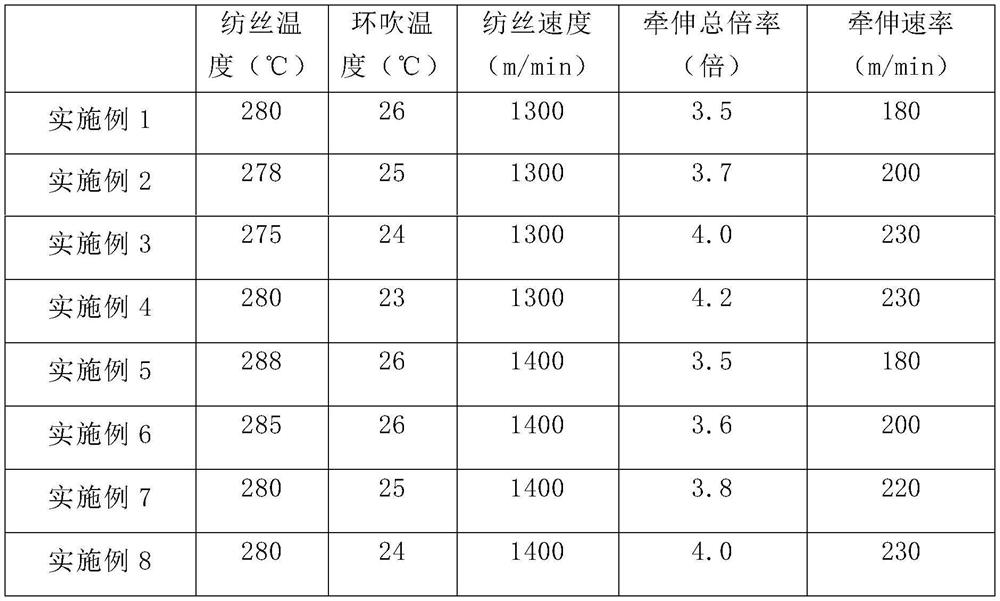

[0023] The raw materials terephthalic acid and ethylene glycol are beaten according to the mass ratio of 1:1.8; and the tetrabutyl titanate catalyst ethylene glycol solution diluted to 0.04wt% and 0.003-0.005wt% pentaerythritol are added to participate in the preparation of the slurry.

[0024] The prepared slurry is sent to the esterification reaction kettle, and the esterification reaction is carried out at a gauge pressure of 0.08MPa and a temperature of 260°C to generate an intermediate bishydroxyethyl terephthalate, and the reaction is carried out until the esterification rate is at least 92%. The water generated in the chemical process is distilled out with the ethylene glycol, and after the water is separated by the fractionating tower, 99wt% of the ethylene glycol is refluxed in the kettle. Bishydroxyethyl terephthalate enters the pre-condensation reactor through the intermediate pipeline.

[0025] Barium sulfate is transported to the intermediate pipeline according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com