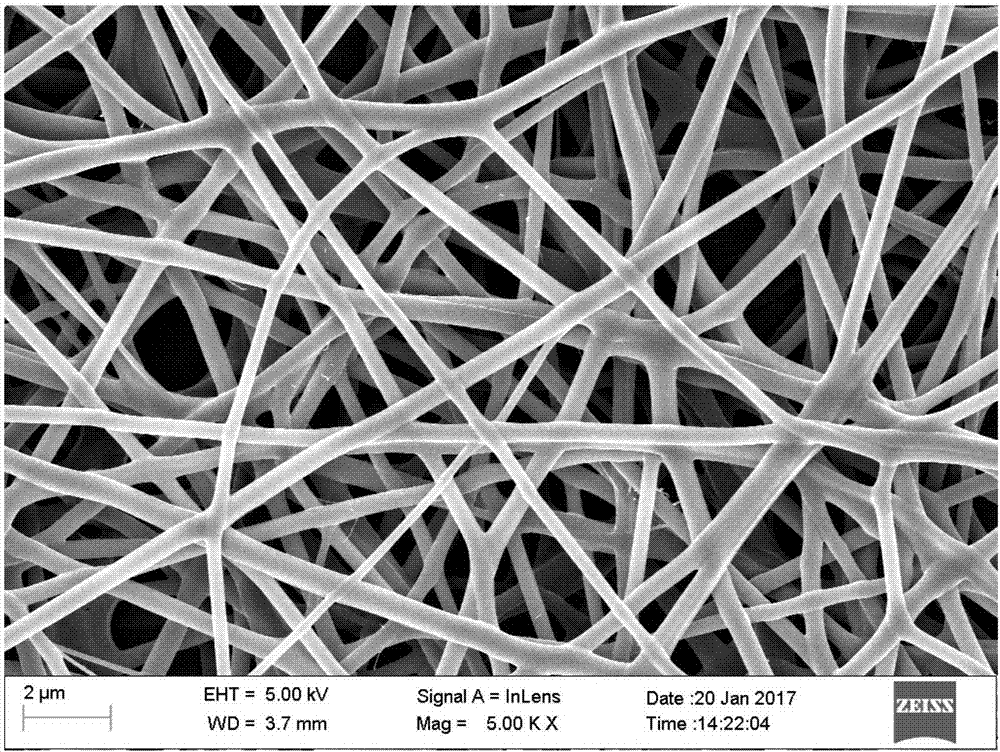

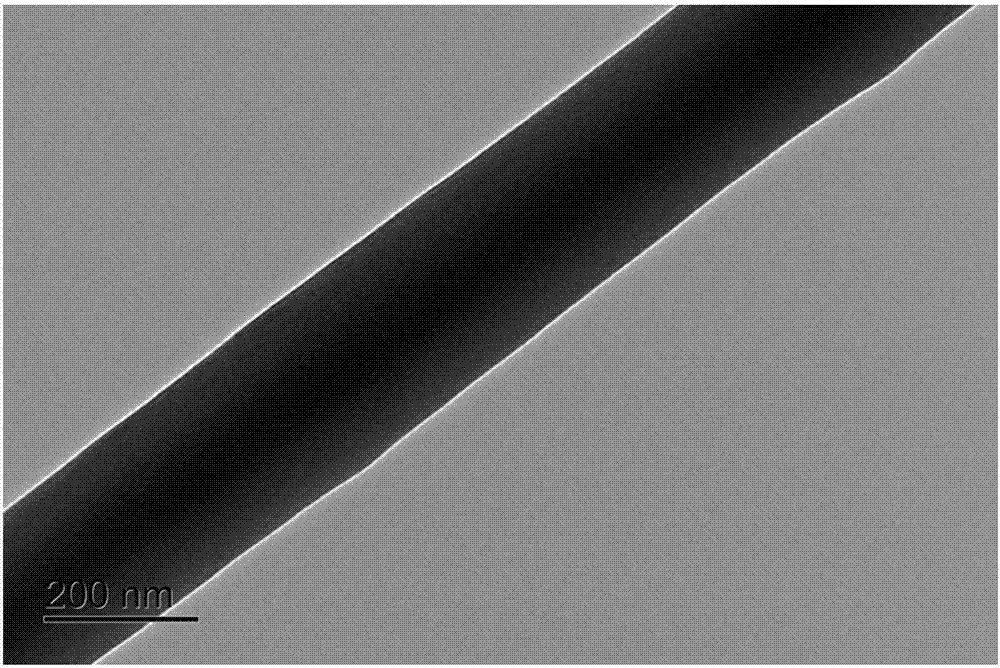

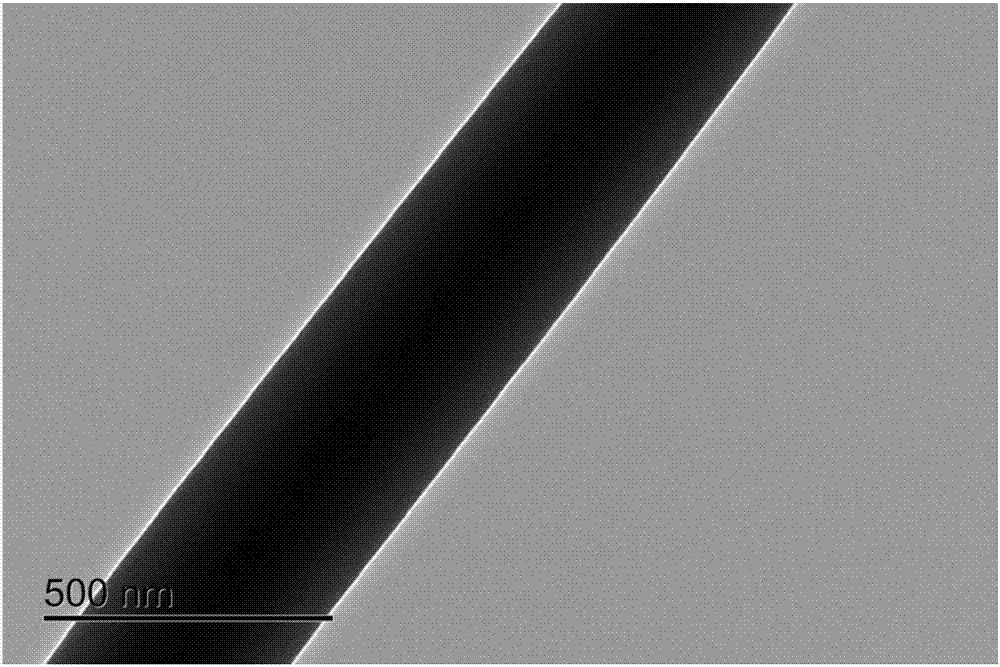

Method for preparing nanofiber membrane with core/shell wrapping structure through coaxial dual-layer electrostatic spinning and application thereof

A nanofiber membrane and electrospinning technology, applied in the field of biomedical composite materials, can solve the problems of bionic wound dressing function, bionic skin extracellular matrix, etc., achieve good biocompatibility and biodegradability, raw materials Rich in resources, beneficial to the effect of gas exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take by weighing 0.2g PCL and 0.2g type I collagen (the mass ratio of PCL and type I collagen is 1:1) with electronic balance, be dissolved in 5ml hexafluoroisopropanol, obtain mass volume ratio concentration and be 8% (m / v ) core layer solution; Weigh 1.425g PLGA and 0.075g fibrinogen (PLGA and fibrinogen mass ratio is 19:1), dissolve in 5ml mixed solution (chloroform: PBS=9:1), get Shell solution with mass volume ratio concentration of 30% (m / v). The solution was magnetically stirred at room temperature for 12 hours to dissolve completely, and then coaxial electrospinning was started after standing for 5 minutes; the parameters of electrospinning were: electrostatic voltage 30kV, receiving distance 12cm, core layer solution propulsion rate 0.05ml / h, shell layer solution The propulsion rate is 0.1ml / h, and the relative humidity is 50%.

Embodiment 2

[0031] Take by weighing 0.16g PVP and 0.04g type I collagen (the mass ratio of PVP and type I collagen is 4:1) with electronic balance, be dissolved in 5ml hexafluoroisopropanol, obtain mass volume ratio concentration and be 4% (m / v ) core solution; Weigh 0.375g PLLA and 0.375g fibrinogen (the mass ratio of PLLA and fibrinogen is 1:1), dissolve in 5ml mixed solution (DMF:DCM:MEM=2:7:1) , to obtain a shell solution with a mass volume ratio concentration of 15% (m / v). The solution was magnetically stirred at room temperature for 12 hours to dissolve completely, and after standing for 5 minutes, coaxial electrospinning was started; the parameters of electrospinning were: electrostatic voltage 23kV, receiving distance 18cm, core solution advancing rate 1ml / h, shell solution advancing Rate 2.7ml / h, relative humidity 70%.

Embodiment 3

[0033] Take by weighing 0.54g PGA and 0.06g type I collagen (the mass ratio of PGA and type I collagen is 9:1) with electronic balance, be dissolved in 5ml hexafluoroisopropanol, obtain mass volume ratio concentration and be 12% (m / v ) core layer solution; Weigh 1.035g PLA and 0.115g fibrinogen (PLA and fibrinogen mass ratio is 9:1), dissolve in 5ml mixed solution (THF: normal saline=9:1), get the mass A shell solution with a concentration of 23% (m / v) by volume. The solution was magnetically stirred at room temperature for 12 hours to dissolve completely, and after standing for 5 minutes, coaxial electrospinning was started; the parameters of electrospinning were: electrostatic voltage 16kV, receiving distance 8cm, core solution advancing rate 0.2ml / h, shell solution The propulsion rate is 0.5ml / h, and the relative humidity is 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com