Compound cycloidal reducer

A cycloidal reducer, compound technology, applied in the direction of transmission, gear transmission, belt/chain/gear, etc., can solve the problems of difficult complete balance, poor assembly performance of the whole machine, poor axial bending rigidity, etc., and achieve improvement The effect of transmission rigidity and load-carrying capacity, reduction of structural size, and guarantee of machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

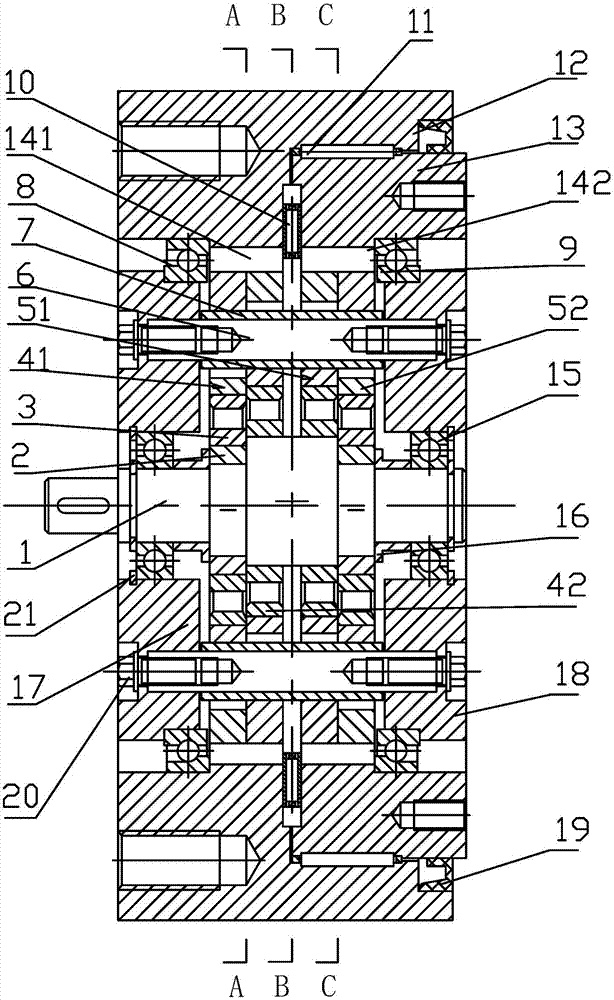

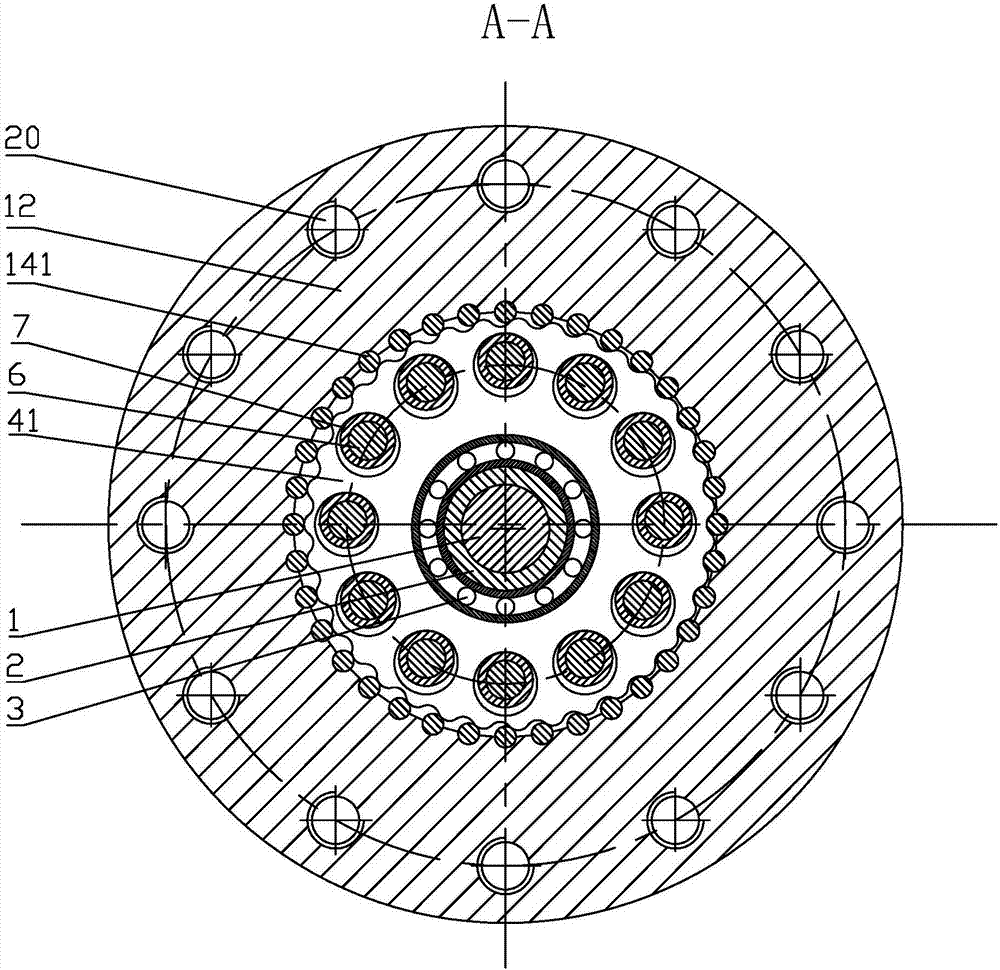

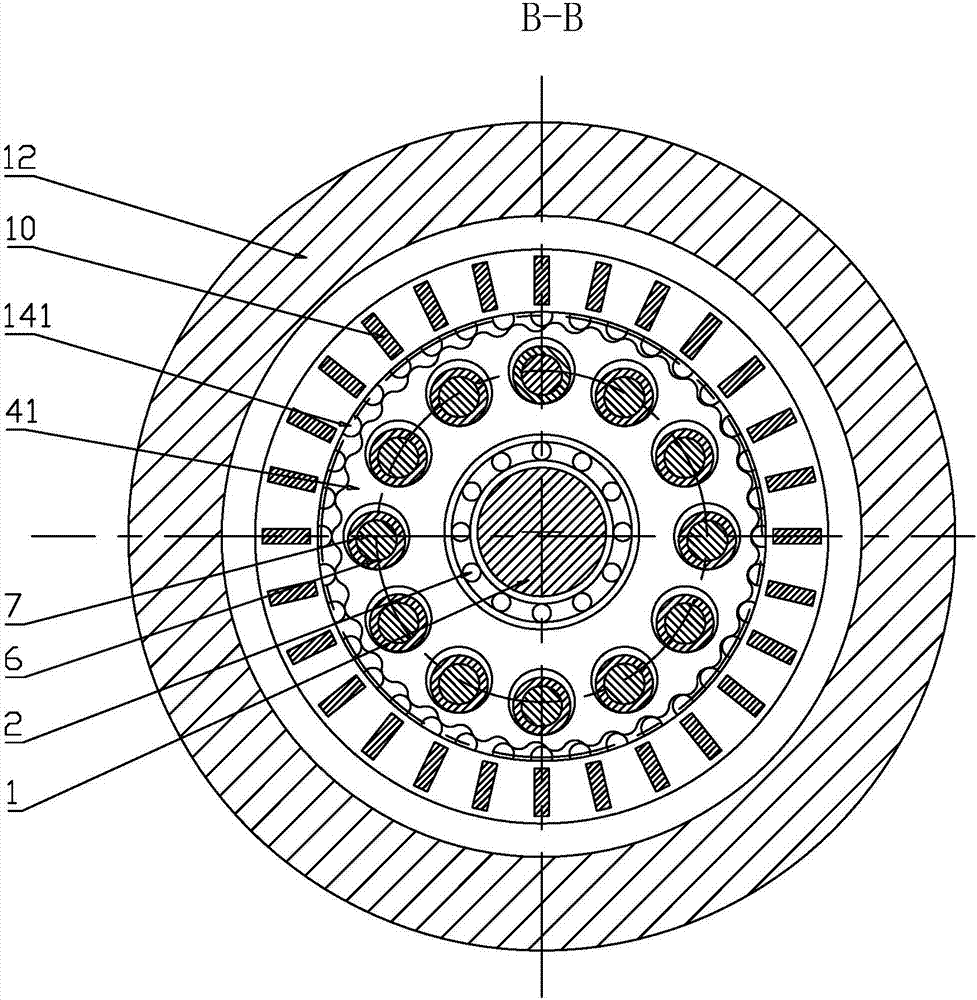

[0017] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

[0018] A compound cycloid reducer proposed by the present invention, such as figure 1 As shown, it includes an input shaft 1 , a fixed pinion housing 12 and an output pinion housing 13 .

[0019] The input shaft 1 is an eccentric shaft with three eccentric positions, including an eccentric section in the middle and eccentric sections on both sides. Among the eccentric sections on both sides, the left side is the eccentric section on the input side, and the right side is the eccentric section on the output side. The eccentric section is equipped with a first-stage left-set cycloidal wheel 41, and the middle eccentric section is equipped with a first-stage right-set cycloida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com