Carbon sphere-carbon nitride (C3N4) nanomaterial and preparation and application thereof

A nanomaterial, carbon nitride technology, applied in the field of environmental catalysis and nanomaterials, can solve the problems of narrow-band semiconductors prone to photocorrosion, unstable organic dye photosensitization, low absorption coefficient, etc. The effect of improved utilization and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) Weigh 20 g of urea, place it in an alumina crucible, and cover it for calcination in an air atmosphere. Raise the temperature from room temperature to 550 °C at a heating rate of 4 °C / min, maintain at 550 °C for 2 hours, and cool down to room temperature naturally.

[0060] (2) Grinding and dissolving the cooled sample in 100 ml of water, and putting it into an ultrasonic pool for 12 hours of ultrasonication.

[0061] (3) Place the sample in a centrifuge with a rotating speed of 10000r / min, centrifuge for 5 minutes, and separate the supernatant.

[0062] (4) Repeat this step until the supernatant appears colorless (or slightly yellow), and repeat the centrifugation for a total of 4 times in this experiment.

[0063] (5) Preserve the precipitate for later use, freeze-dry for 13 hours to obtain sample C3N4.

[0064] (6) Dissolve 2g of C3N4 in 10ml of ethylenediamine, mix and stir evenly, and number it as solution 1.

[0065] (7) Dissolve 50mg of citric acid in 2ml ...

Embodiment 2

[0079] Slowly add 0.05g of glucose into 2ml of ethylene glycol solution, stir at room temperature and ultrasonically make it fully mixed; 3 N 4 Slowly add 10ml of ethylene glycol, stir at room temperature and sonicate to make it evenly mixed. The two mixed solutions were stirred at room temperature to fully mix to form a homogeneous solution. Add the mixed solution into a hydrothermal kettle, heat it to 200°C for 30min, and keep it at 200°C for 24h. After the reaction is completed, cool, centrifuge, and dry to obtain a powder sample.

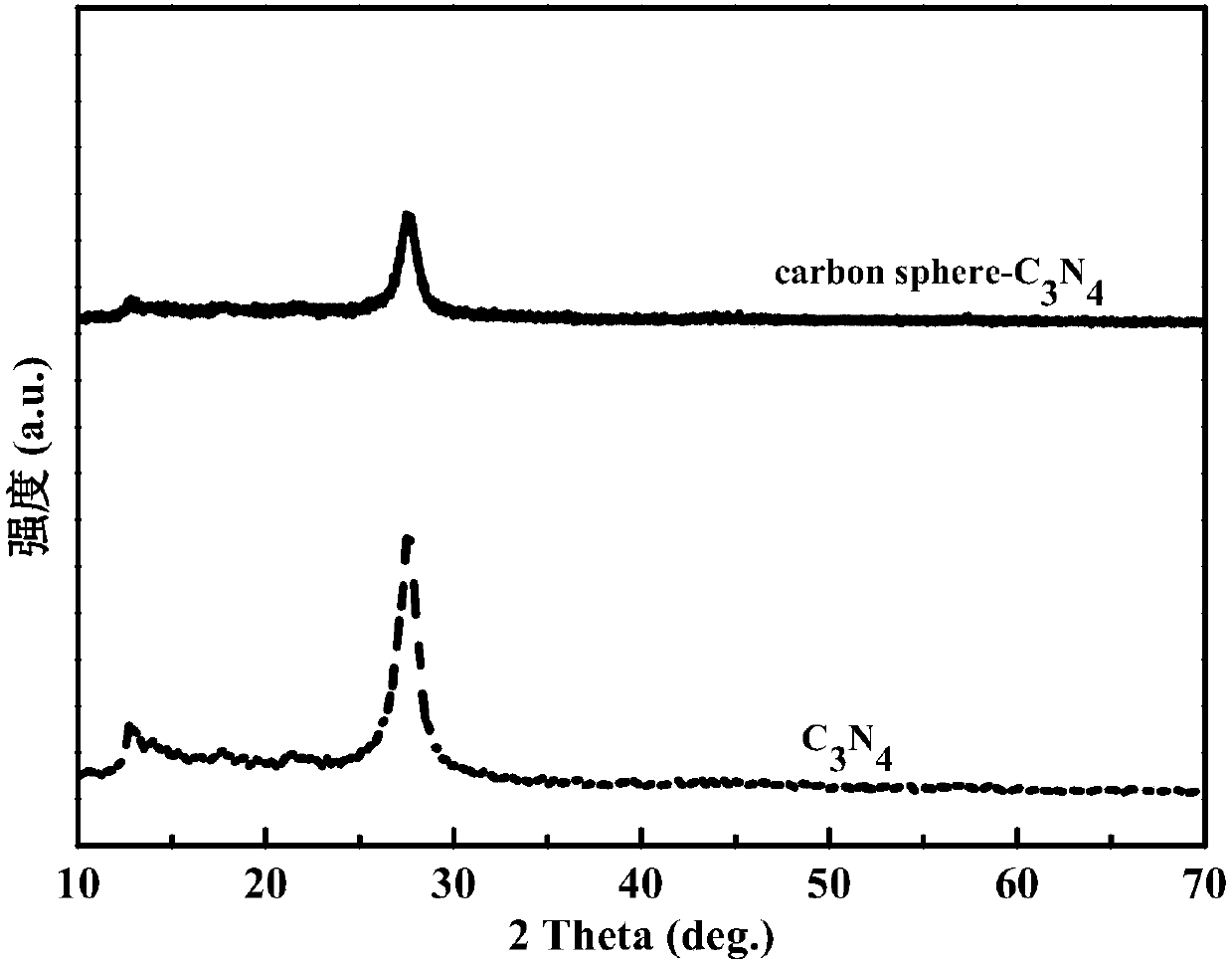

[0080] figure 1 Pure C prepared for Example 1 3 N 4 and carbon sphere-C 3 N 4 The X-ray powder diffraction pattern; due to the carbon sphere loading in C 3 N 4 Surface, carbon sphere modified C 3 N 4 Due to the low carbon sphere content and high dispersion, no diffraction peak changes can be seen, indicating that the introduction of carbon photons will not change the C 3 N 4 chemical structure.

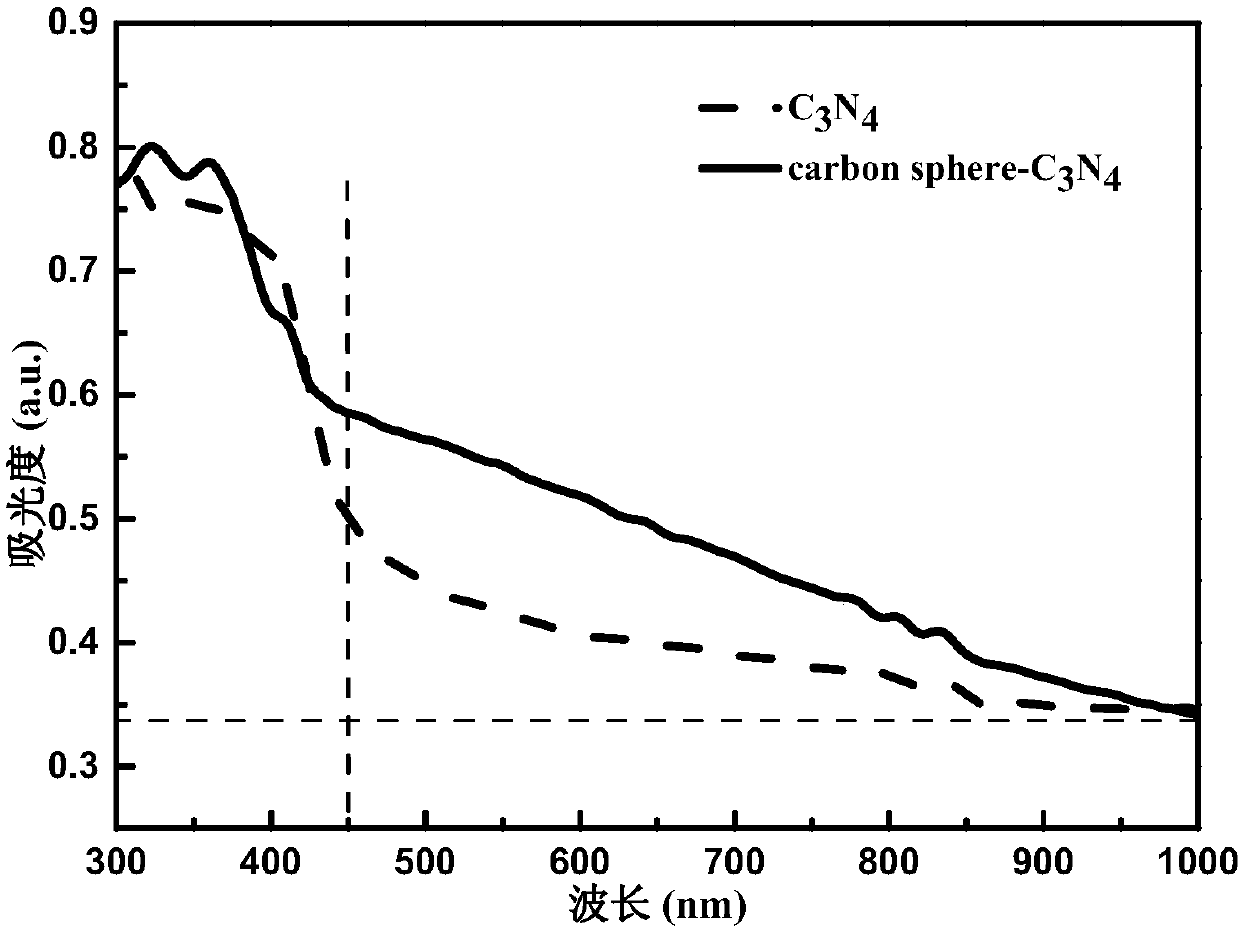

[0081] figure 2 Pure C prepared for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com