Method for high-depth purification of heavy metals in water by utilizing titanium phosphate nano flower material

A technology of coating materials and nanoflowers, applied in chemical instruments and methods, coatings, cation exchange materials, etc., can solve the problems of mass transfer and utilization, and achieve the effect of high selectivity and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Measure 1.2 mL of butyl titanate and dissolve 50 mL of ethanol to prepare a 3% butyl titanate-ethanol solution, and add 10 g of D001 type cation exchange resin (manufactured by Hangzhou Zhengguang Industrial Co., Ltd.) into the butyl titanate-ethanol solution , at 40° C., fully stirred and reacted for 5 hours, then added 100 mL of phosphoric acid solution with a mass concentration of 70%, and reacted for 5 hours to form a titanium phosphate nanoflower coating material with a nano-titanium phosphate loading of 5.8%.

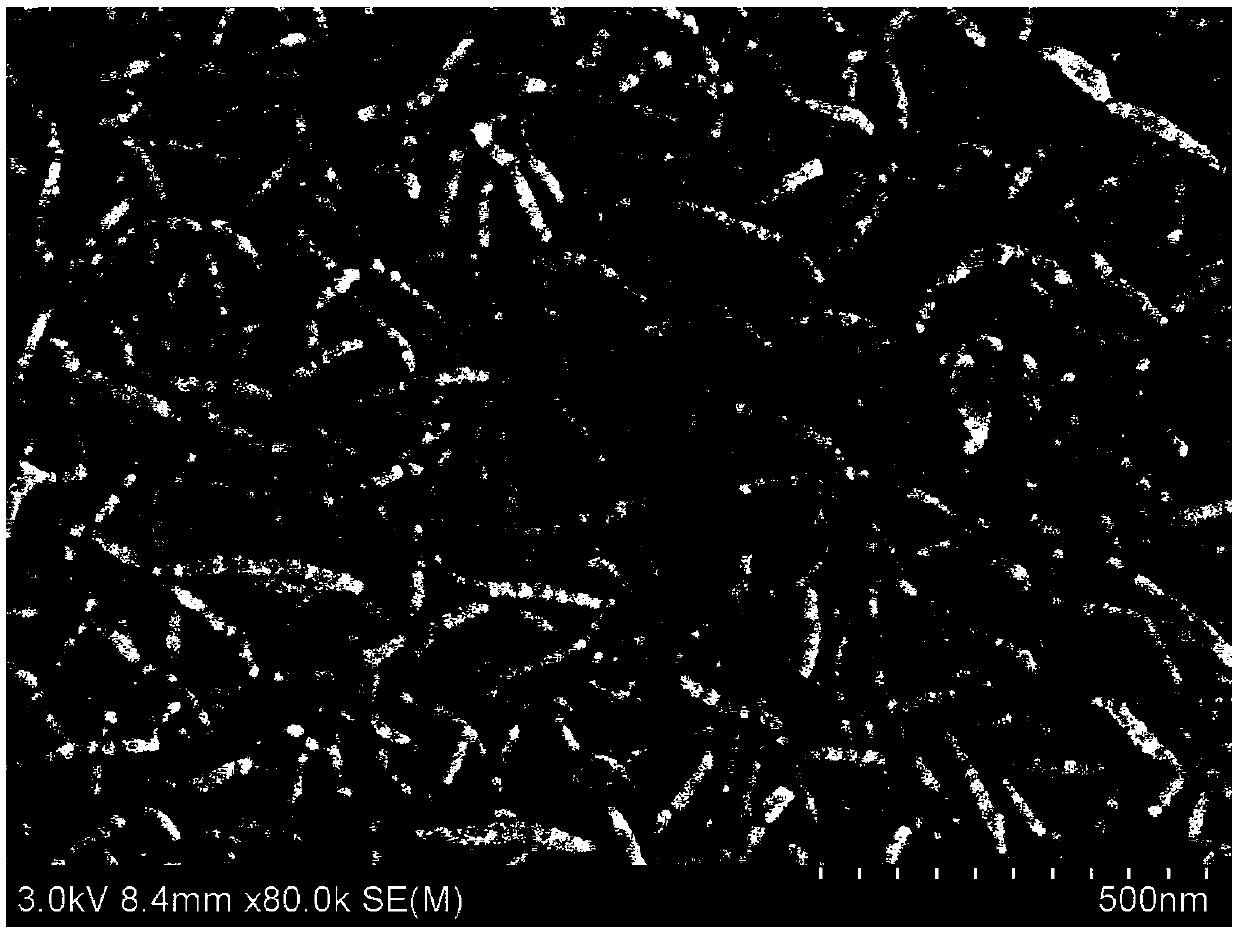

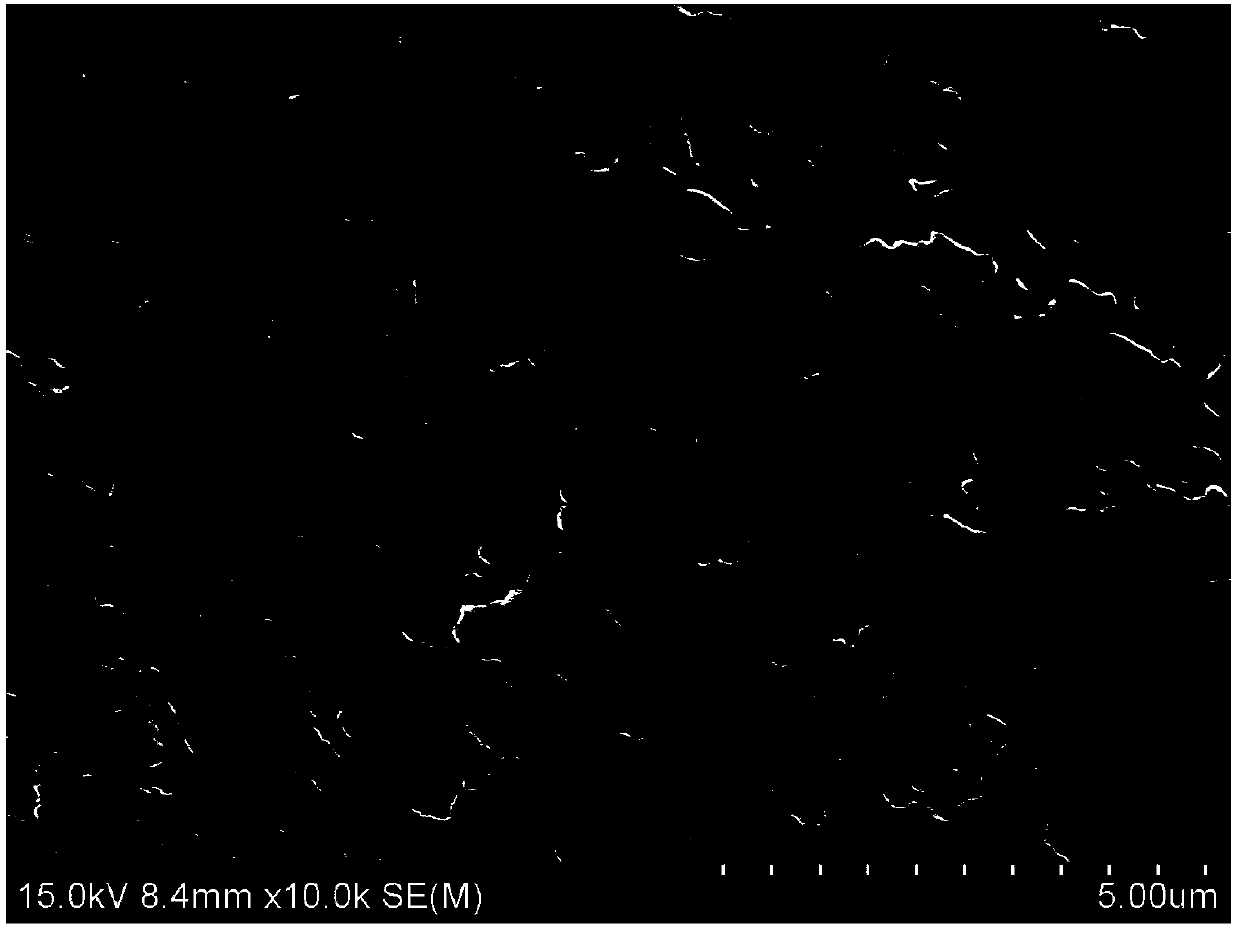

[0021] Such as figure 1 As shown, compared with its parent D001 (such as figure 2 As shown), the surface of the resin is coated with a rich nano-titanium phosphate flower-like coating, which fully proves that the preparation is successful.

[0022] Put 15mL of the above-mentioned composite material in a glass adsorption column (ф12×220mm) and put heavy metal-containing water (Pb=0.1mg / L and Ca(II)=200mg / L, Mg(II)=300mg / L, Na(I) =260mg / L, pH=3) flow throu...

Embodiment 2

[0024] Measure 36 mL of butyl titanate and dissolve 150 mL of ethanol to prepare a 30% butyl titanate-ethanol solution, add 20 g of 001x7 type cation exchange resin (manufactured by Hangzhou Zhengguang Industrial Co., Ltd.) to the butyl titanate-ethanol solution, At 60° C., fully stirred and reacted for 12 hours, then added 200 mL of phosphoric acid solution with a mass concentration of 85%, reacted for 20 hours, and formed a titanium phosphate nanoflower coating material with a nano-titanium phosphate loading of 26.3%.

[0025] Put 20mL of the above composite material in a glass adsorption column (ф12×220mm) and put the heavy metal-containing water (Hg=200mg / L and Ca(II)=300mg / L, Mg(II)=120mg / L, Na(I)= 230mg / L, pH=7) flow through the adsorption column equipped with resin-based composite materials from top to bottom, the temperature is controlled at 55°C, the flow rate is 50BV / h, and the concentration of Hg(II) ions in the effluent is 10ppb after being treated by the adsorbent ...

Embodiment 3

[0027] Measure 13.6 mL of butyl titanate and dissolve 170 mL of ethanol to prepare a 10% butyl titanate-ethanol solution, and add 10 g of D113 cation exchange resin (manufactured by Hangzhou Zhengguang Industrial Co., Ltd.) to the butyl titanate-ethanol solution , at 50° C., fully stirred and reacted for 8 hours, then added 200 mL of phosphoric acid solution with a mass concentration of 75%, and reacted for 10 hours to form a titanium phosphate nanoflower coating material with a nano-titanium phosphate loading of 12.1%.

[0028] Put 30mL of the above composite material in a glass adsorption column (ф12×220mm) and put heavy metal-containing water (Cd=1mg / L and Ca(II)=400mg / L, Mg(II)=100mg / L, Na(I)= 360mg / L, pH=4.5) flow through the adsorption column equipped with resin-based composite material from top to bottom, the temperature is controlled at 25°C, the flow rate is 20BV / h, and the concentration of Pb(II) ions in the effluent after adsorbent treatment is 2ppb Below, the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com