Layered hydrotalcite modified PLLA

A hydrotalcite, layered technology, applied in the field of barrier PLLA and its preparation, can solve the problem that it is difficult to improve the comprehensive performance of PLLA, thermal stability, barrier property, solvent resistance, and flame retardancy. Other properties of materials, etc., to achieve the effect of improving mechanical properties, improving barrier properties, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

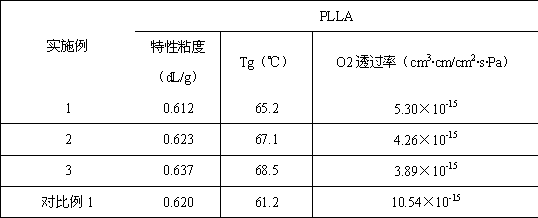

Examples

Embodiment 1

[0037] (1) Modify the layered hydrotalcite with an aminosilane coupling agent to obtain the modified layered hydrotalcite;

[0038] (2) Place the modified layered hydrotalcite in an organic solvent and ultrasonically disperse for 1-60 minutes to obtain a layered hydrotalcite suspension;

[0039] (3) Dissolve excess trimellitic anhydride in acetone to obtain a trimellitic anhydride acetone solution; then add it to the layered hydrotalcite suspension, stir, and react at a certain temperature for 5-30 minutes to obtain a trimellitic anhydride modified layered hydrotalcite solution ,spare;

[0040] (4) Replace the gas in the reactor with nitrogen, add 415.0g of terephthalic acid and ethylene glycol into the reactor, heat up, stir, and perform the esterification reaction at 200°C. When the degree of esterification is above 90%, add The layered hydrotalcite solution modified by the catalyst and trimellitic anhydride was heated to 280° C., while vacuuming and polycondensation for 1.5 hours...

Embodiment 2

[0044] (1) Modify the layered hydrotalcite with an aminosilane coupling agent to obtain the modified layered hydrotalcite;

[0045] (2) Place the modified layered hydrotalcite in an organic solvent and ultrasonically disperse for 1-60 minutes to obtain a layered hydrotalcite suspension;

[0046] (3) Dissolve trimellitic anhydride in acetone to obtain a trimellitic anhydride acetone solution; then add it to the layered hydrotalcite suspension, stir, and react at a certain temperature for 5-30 minutes to obtain a trimellitic anhydride-modified layered hydrotalcite solution for use. ;

[0047] (4) Replace the gas in the reactor with nitrogen, add 415.0g of terephthalic acid and 184.1g of ethylene glycol into the reactor, increase the temperature, stir, and carry out the esterification reaction at 200°C until the degree of esterification is over 90% Adding the catalyst and the layered hydrotalcite solution modified by trimellitic anhydride, raising the temperature to 280°C, vacuuming at...

Embodiment 3

[0051] (1) Modify the layered hydrotalcite with an aminosilane coupling agent to obtain the modified layered hydrotalcite;

[0052] (2) Place the modified layered hydrotalcite in an organic solvent and ultrasonically disperse for 1-60 minutes to obtain a layered hydrotalcite suspension;

[0053] (3) Dissolve trimellitic anhydride in acetone to obtain a trimellitic anhydride acetone solution; then add it to the layered hydrotalcite suspension, stir, and react at a certain temperature for 5-30 minutes to obtain a trimellitic anhydride-modified layered hydrotalcite solution, ready for use ;

[0054] (4) Replace the gas in the reactor with nitrogen, add 415.0g of terephthalic acid and 184.1g of ethylene glycol into the reactor, increase the temperature, stir, and carry out the esterification reaction at 200°C. When the degree of esterification is above 90% , Adding a catalyst and a layered hydrotalcite solution modified by trimellitic anhydride, raising the temperature to 280°C, vacuumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com