Preparation method of concentrated sugarcane juice

A technology of sugarcane juice and sugarcane raw juice, which is applied in food science, food preservation, food ingredients as taste improvers, etc. It can solve the problems of product residue graininess, complicated preparation process, and insufficient sterilization intensity, etc., and achieve sterilization Good effect, simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

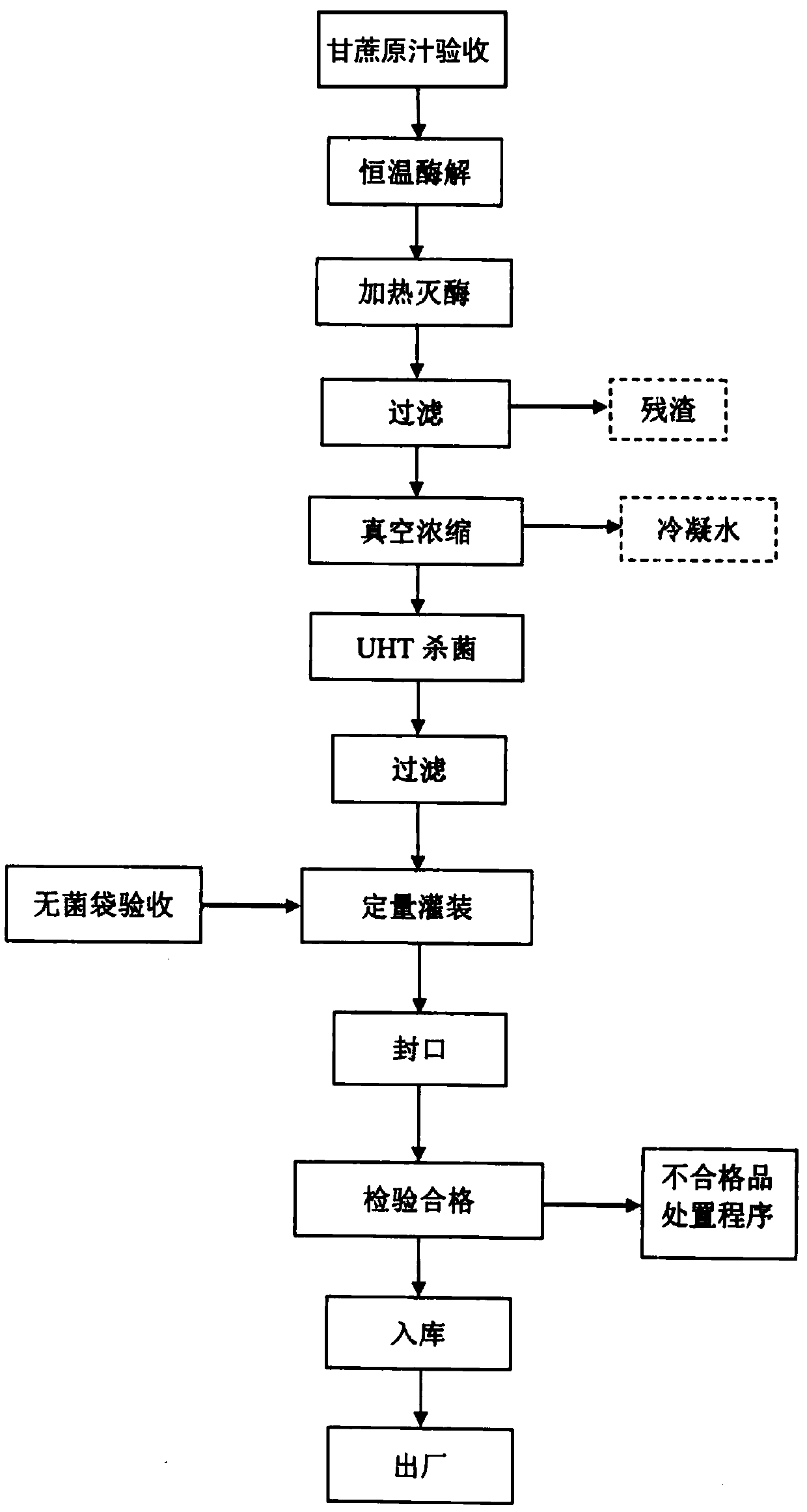

[0035] Such as figure 1 Shown, a kind of preparation method of concentrated sugarcane juice comprises:

[0036] Acceptance steps of sugarcane raw juice: acceptance of sugarcane raw juice with a pH of 4.0-6.0 and a sugar content of ≥30;

[0037] Constant-temperature enzymatic hydrolysis step: take qualified sugarcane raw juice, heat the sugarcane raw juice to 50-55°C, then add enzyme preparation, keep the temperature at constant temperature for 85-95min, and obtain the first sugarcane juice;

[0038] Heating enzyme inactivation step: heating the first sugarcane juice to 90-95°C to obtain the second sugarcane juice;

[0039] A filtering step: filtering the second sugarcane juice to obtain the third sugarcane juice;

[0040] Vacuum concentration step: vacuum concentrate the third sugarcane juice, then cool to below 30°C to obtain the fourth sugarcane juice;

[0041] UHT sterilization step: pump the fourth sugarcane juice into the UHT sterilizer, and obtain the fifth sugarcane ...

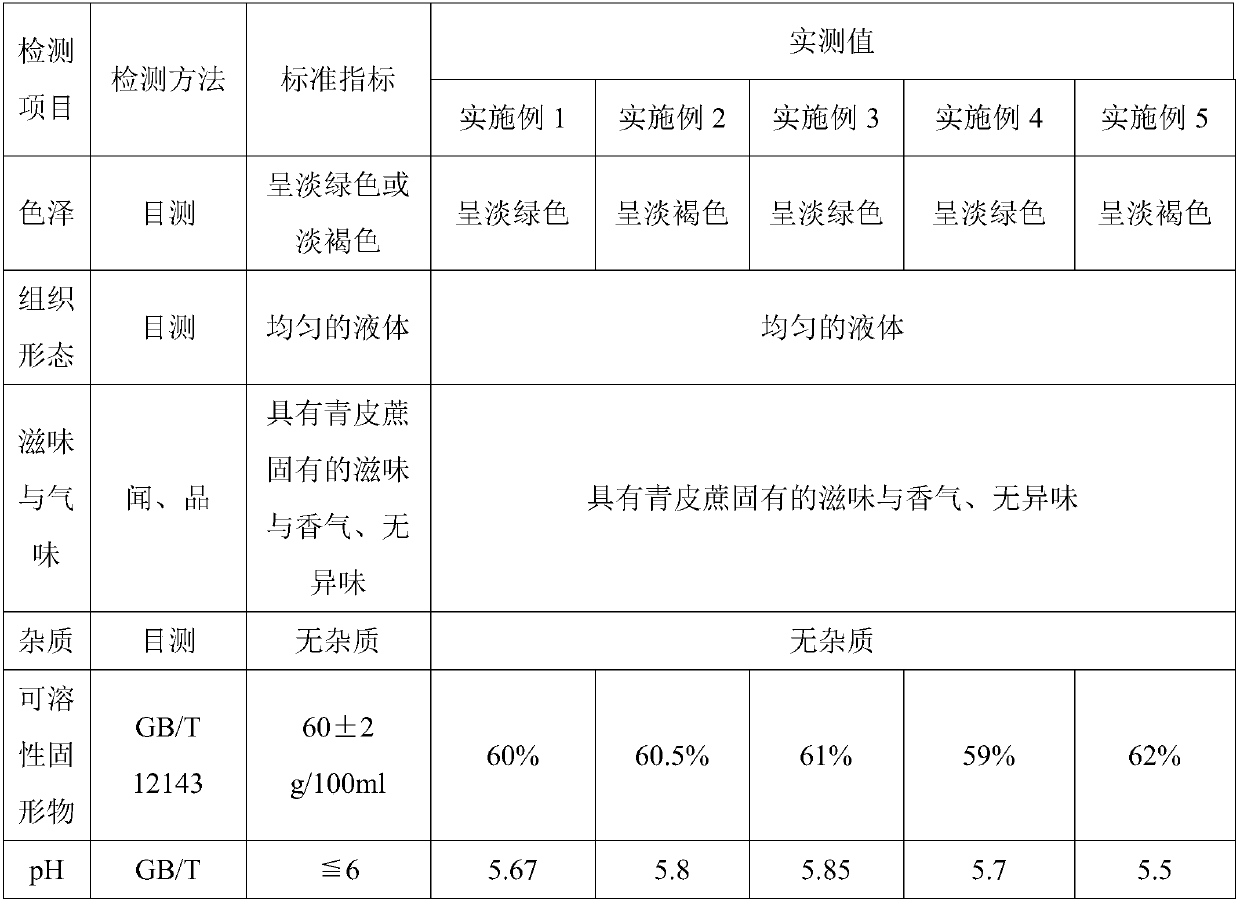

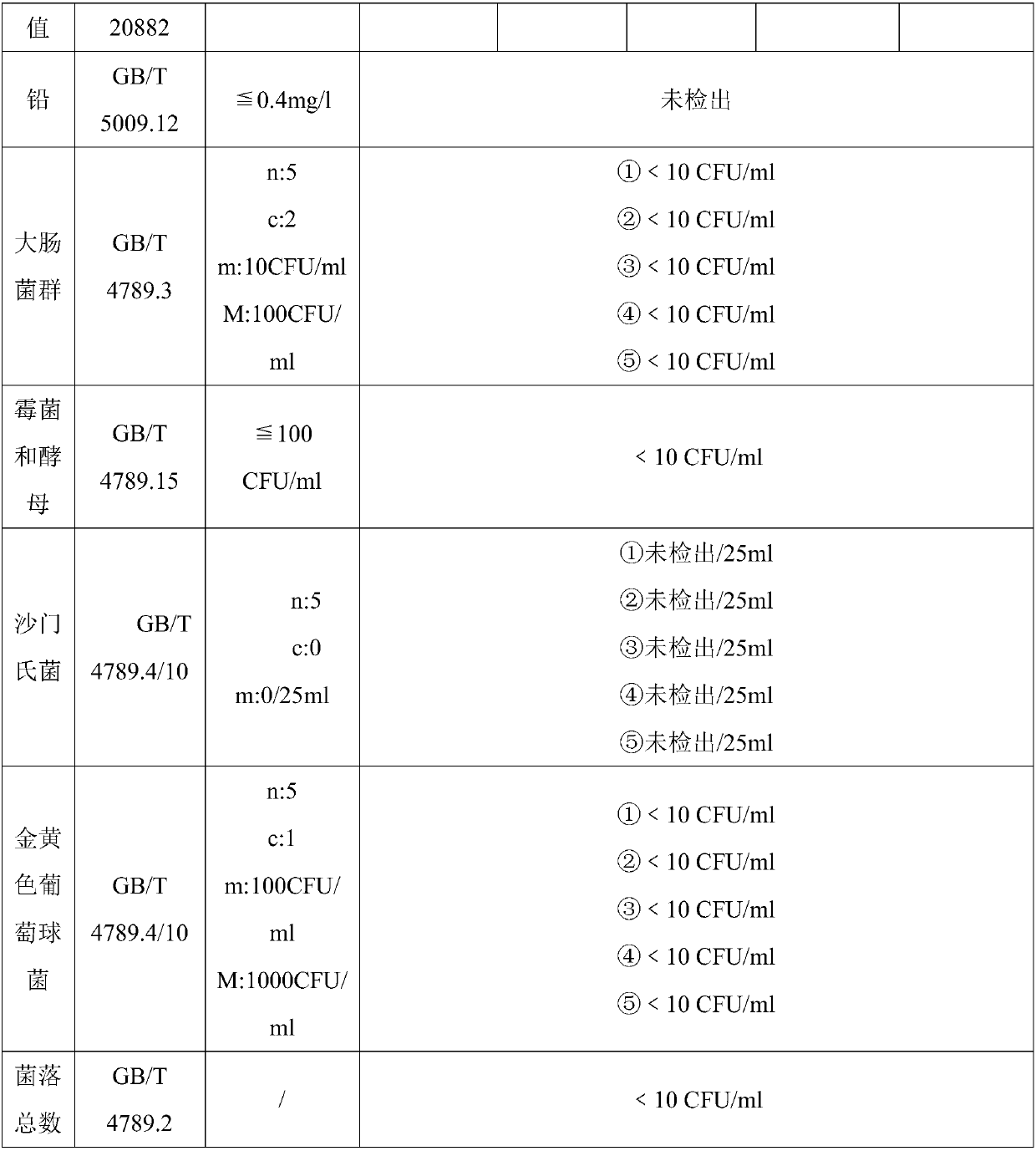

Embodiment 1

[0060] A preparation method of concentrated sugarcane juice, comprising:

[0061] Acceptance steps of sugarcane raw juice: acceptance of sugarcane raw juice with a pH of 4.0-6.0 and a sugar content of ≥30;

[0062] Constant temperature enzymatic hydrolysis step: Put the raw sugarcane juice into a stainless steel storage tank, open the steam valve, automatically adjust the steam volume through the temperature and pressure reduction device, heat the raw sugarcane juice to 55°C through a heat exchanger, and then add neutral protease and The total amount of pectinase, neutral protease and pectinase added is 0.2% of the sugarcane raw juice mass, and the temperature is maintained for 90min to obtain the first sugarcane juice;

[0063] Heating enzyme deactivation step: open the steam valve, adjust the steam volume through the temperature and pressure reduction device, and heat the first sugarcane juice to 95°C through a heat exchanger to obtain the second sugarcane juice;

[0064] P...

Embodiment 2

[0070] The difference between embodiment 2 and embodiment 1 is:

[0071] In the constant temperature enzymatic hydrolysis step, the raw sugarcane juice is heated to 50° C., and then neutral protease is added. The amount of neutral protease added is 0.2% of the mass of the raw sugarcane juice, and the temperature is maintained for 95 minutes to obtain the first sugarcane juice;

[0072] In the step of heating to kill enzymes, heating the first sugarcane juice to 90°C to obtain the second sugarcane juice;

[0073] In the vacuum concentration step, set the vacuum degree to be-100Kpa;

[0074] In the UHT sterilization step, the sterilization temperature is 121°C, and the sterilization time is 35s.

[0075] Others are identical with specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com