Preparation method of dry nano-fiber facial mask

A nanofiber and mask technology, applied in the field of mask manufacturing, can solve the problem of high waste of nutrient solution and achieve the effects of convenient transportation and storage, prolonging shelf life and increasing comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

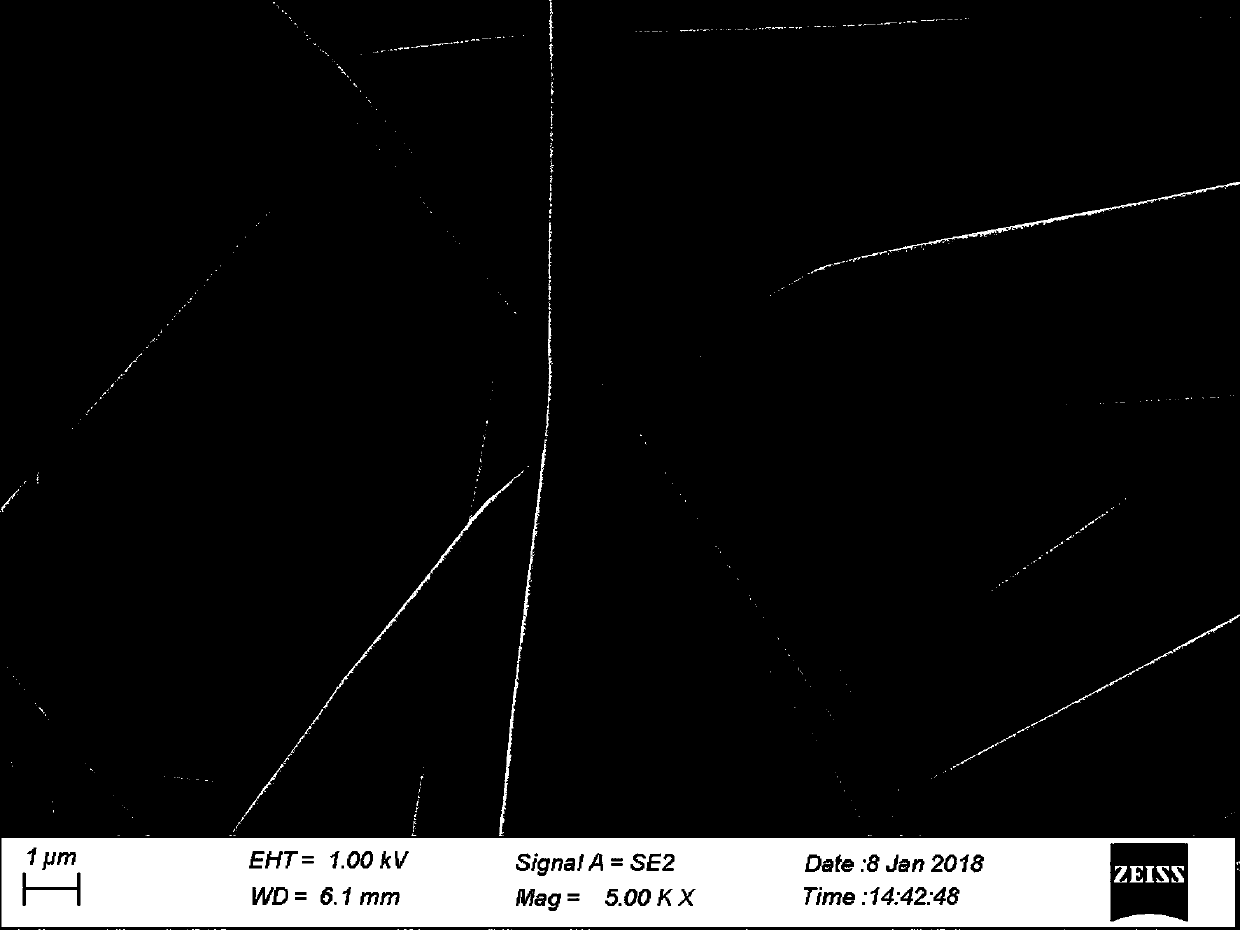

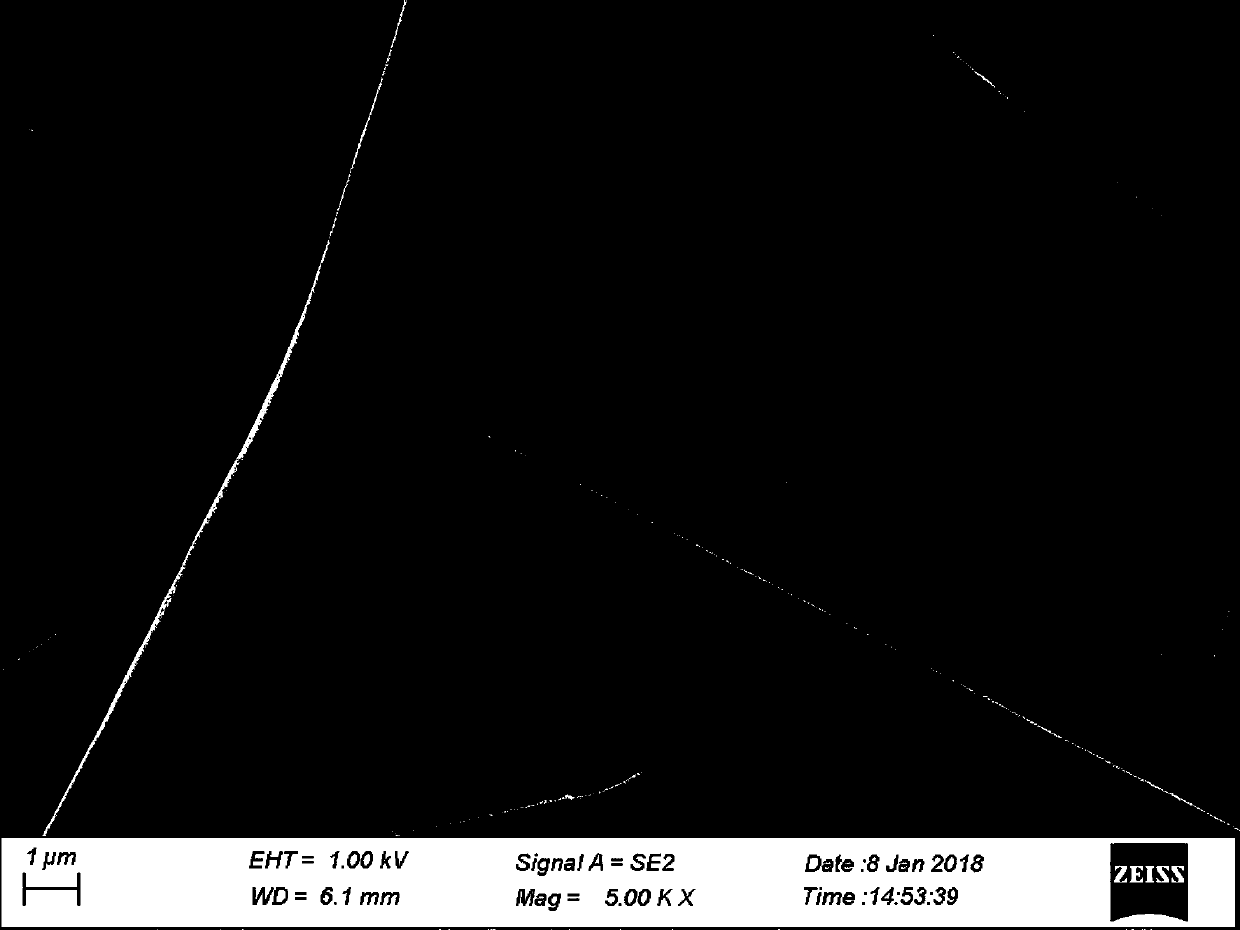

Image

Examples

Embodiment 1

[0029] A preparation method based on nanofiber dry mask, comprising the following steps:

[0030] 1) Put polyvinyl alcohol slices with a degree of polymerization of 500 and a degree of alcoholysis of less than 90% into deionized water, stir at room temperature for 0.5 hours to fully swell the sample, and then quickly heat to above 60°C and stir for 1 hour to obtain 10% polyvinyl alcohol Polyvinyl alcohol aqueous solution;

[0031] 2) Carboxymethyl chitosan was dissolved in deionized water at room temperature to obtain a chitosan aqueous solution with a mass fraction of 1%; the carboxymethyl chitosan had a carboxylation degree of 83.58% and a relative molecular weight greater than 5000 chitosan;

[0032] 3) Sodium hyaluronate was dissolved in acetic acid aqueous solution with a mass fraction of 10% and stirred at room temperature for 5 hours to obtain a sodium hyaluronate solution with a mass fraction of 0.1%;

[0033] 4) dissolving sericin in water to prepare a nutrient solu...

Embodiment 2

[0039] A preparation method based on nanofiber dry mask, comprising the following steps:

[0040] 1) Put polyvinyl alcohol slices with a degree of polymerization of 2500 and a degree of alcoholysis of less than 90% into deionized water, stir at room temperature for 1 hour to fully swell the sample, then quickly heat to above 60°C and stir for 3 hours to obtain 20% polyvinyl alcohol Polyvinyl alcohol aqueous solution;

[0041] 2) Carboxymethyl chitosan was dissolved in deionized water at room temperature to obtain a chitosan aqueous solution with a mass fraction of 10%; the carboxymethyl chitosan had a carboxylation degree of 83.58% and a relative molecular weight greater than 5000 chitosan;

[0042] 3) Sodium hyaluronate was dissolved in acetic acid aqueous solution with a mass fraction of 10% and stirred at room temperature for 24 hours to obtain a sodium hyaluronate solution with a mass fraction of 1%;

[0043] 4) Dissolving silk fibroin peptide in water to prepare a nutri...

Embodiment 3

[0049] A preparation method based on nanofiber dry mask, comprising the following steps:

[0050] 1) Put polyvinyl alcohol slices with a degree of polymerization of 1500 and an alcoholysis degree of less than 90% into deionized water, stir at room temperature for 0.7 hours to fully swell the sample, and then quickly heat to above 60°C and stir for 2 hours to obtain 15% polyvinyl alcohol Polyvinyl alcohol aqueous solution;

[0051] 2) Carboxymethyl chitosan was dissolved in deionized water at room temperature to obtain a chitosan aqueous solution with a mass fraction of 5%; the carboxymethyl chitosan had a carboxylation degree of 83.58% and a relative molecular weight greater than 5000 chitosan;

[0052]3) Sodium hyaluronate was dissolved in acetic acid aqueous solution with a mass fraction of 10% and stirred at room temperature for 15 hours to obtain a sodium hyaluronate solution with a mass fraction of 0.5%;

[0053] 4) Dissolving the extract of Chinese herbal medicine raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com