Composition, tablet and application thereof containing fucoidan sulfate

A fucoidan and sulfate technology is applied in the directions of medical preparations containing active ingredients, drug combinations, medical preparations without active ingredients, etc., to achieve the effects of improving immunity, stable dosage form quality, and complete and smooth surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

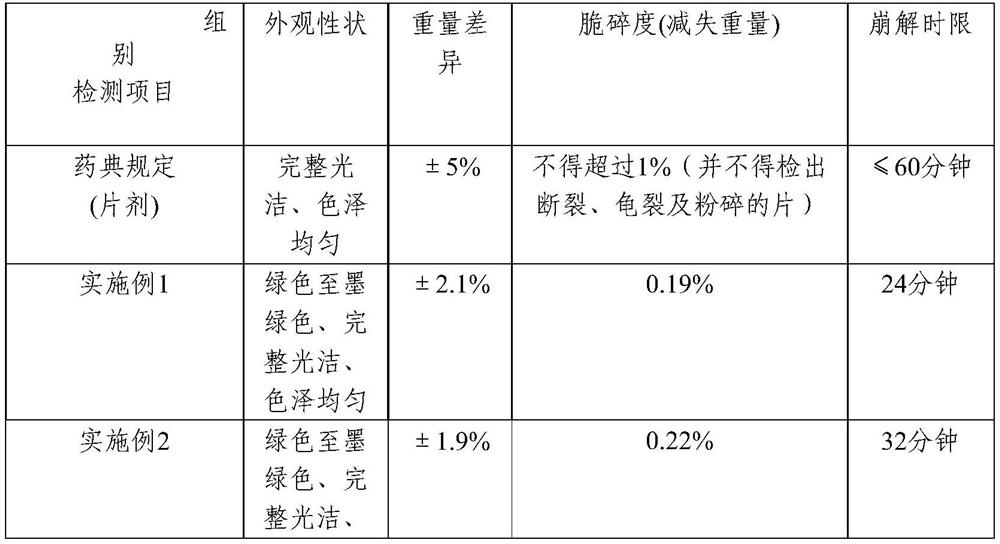

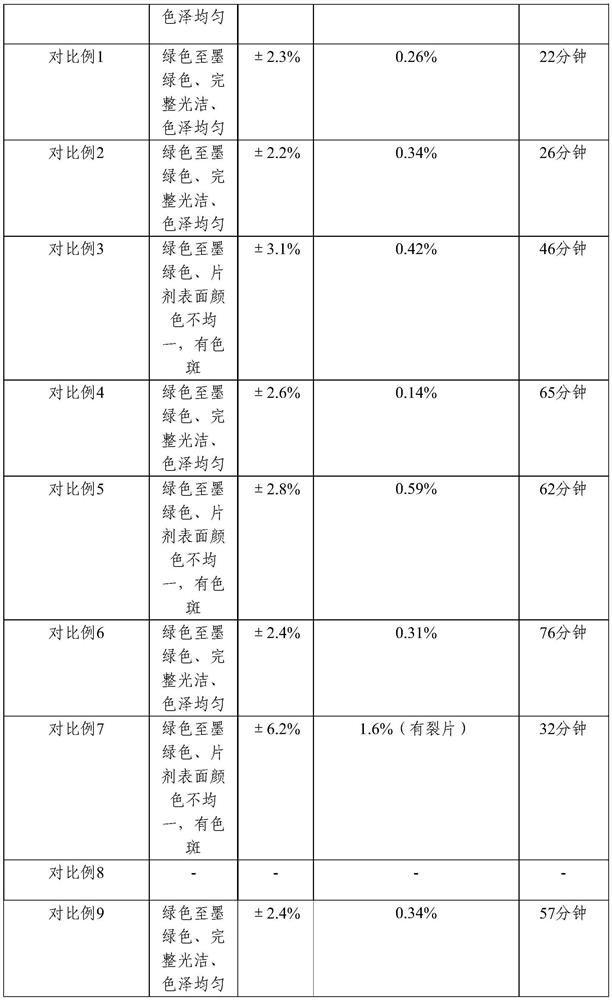

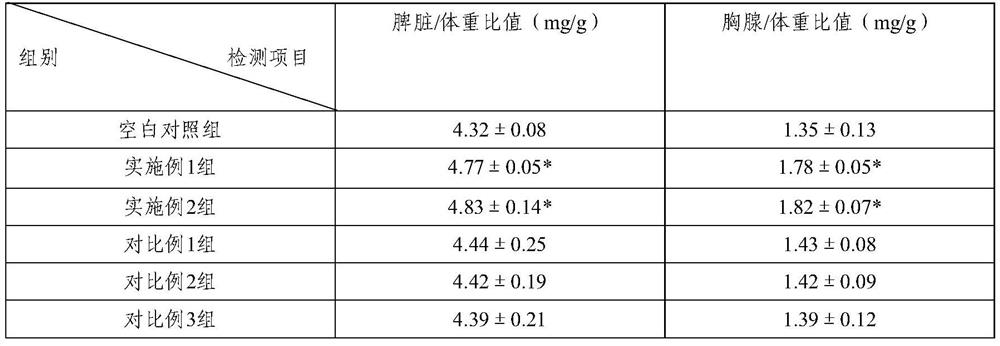

Examples

Embodiment 1

[0040] Embodiment 1 A kind of composition containing fucoidan sulfate ester

[0041] This embodiment provides a tablet containing fucoidan sulfate, which is prepared by the following steps:

[0042] (1) Take 996g of fucoidan sulfate (average molecular weight: 40KDa), 900g of phycocyanin, 2904g of kelp powder, 60g of sodium alginate, 480g of sodium carboxymethyl starch, and 600g of microcrystalline cellulose, and dry at 60°C for 4 hours , over 120 mesh particles, spare.

[0043](2) Mix the dried fucoidan sulfate (the average molecular weight is 40KDa), phycocyanin and microcrystalline cellulose evenly. After the sodium carboxymethyl starch and sodium alginate are evenly mixed, they are evenly mixed with kelp powder in a dry state. Then continue to mix the two groups of mixed granules evenly, add 1200g of water as a binder, make soft materials, sieve and granulate the soft materials, dry the wet granules at 50°C, pass the dry granules through a 18-mesh sieve, and add magnesium...

Embodiment 2

[0044] Embodiment 2 A kind of composition containing fucoidan sulfate ester

[0045] This embodiment provides a tablet containing fucoidan sulfate, which is prepared by the following steps:

[0046] (1) Take 1200g of fucoidan sulfate (average molecular weight: 60KDa), 1080g of phycocyanin, 2640g of wakame powder, 60g of sodium alginate, 360g of corn starch, and 600g of microcrystalline cellulose, and dry them at 60°C for 4 hours. 120 mesh particles, spare.

[0047] (2) Mix the dried fucoidan sulfate (average molecular weight: 60KDa), phycocyanin and microcrystalline cellulose evenly. After the cornstarch and the sodium alginate are mixed evenly, they are evenly mixed with the wakame powder in a dry state. Continue to mix the two groups of mixed granules evenly, add 1200g of water as a binder, make soft materials, sieve and granulate the soft materials, dry the wet granules at 50°C, pass the dry granules through a 18-mesh sieve, and add calcium stearate 30g, 30g of magnesium...

Embodiment 3

[0048] Embodiment 3 A composition containing fucoidan sulfate

[0049] This example provides a chewable tablet containing fucoidan sulfate, which is prepared by the following steps:

[0050] (1) Take 996g of fucoidan sulfate (average molecular weight: 40KDa), 900g of phycocyanin, 2874g of kelp powder, 60g of sodium alginate, 480g of sodium carboxymethyl starch, and 600g of microcrystalline cellulose, and dry at 60°C for 4 hours , over 120 mesh particles, spare.

[0051] (2) Mix the dried fucoidan sulfate (the average molecular weight is 40KDa), phycocyanin and microcrystalline cellulose evenly. After the sodium carboxymethyl starch and sodium alginate are mixed evenly, they are evenly mixed with kelp powder and 30 g of mannitol in a dry state. Then continue to mix the two groups of mixed granules evenly, add 1200g of water as a binder, make soft materials, sieve and granulate the soft materials, dry the wet granules at 50°C, pass the dry granules through a 18-mesh sieve, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com