Layered high niobium-titanium-aluminum alloy composite plate and preparation method thereof

A composite material plate, titanium-aluminum alloy technology, applied in the field of metal-based composite materials and its preparation, composite materials and its preparation, can solve the problem that the performance of a single component material is difficult to meet, and achieve improved material performance and excellent mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

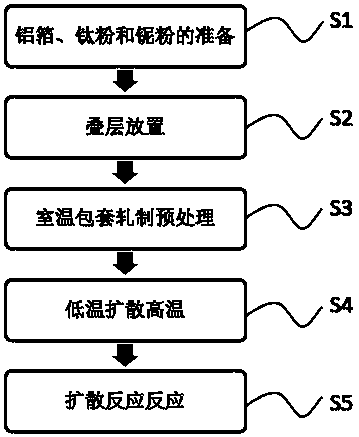

[0032] Specific implementation mode 1: The preparation method of a layered high-niobium titanium-aluminum alloy composite material plate according to this implementation mode is carried out according to the following steps:

[0033] S1: Preparation of aluminum foil, titanium powder and niobium powder: the surface of the aluminum foil is cleaned by a common surface treatment method; at the same time, the titanium powder and niobium powder are mixed evenly;

[0034] S2: Stacked placement: Alternately stack the surface-treated aluminum foil and the mixed powder to form a "sandwich" structure;

[0035] S3: Pretreatment of wrapping and rolling at room temperature: cold-rolling the laminated materials covered with titanium foil at room temperature to make the powder distribution between the aluminum foils more uniform;

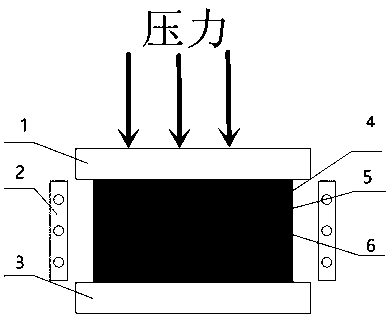

[0036] S4: Low-temperature diffusion reaction: place the laminated structure that has been cold-rolled without removing the sheath in a graphite mold whose surface ...

specific Embodiment approach 2

[0045] Embodiment 2: This embodiment differs from Embodiment 1 in that the thickness of the aluminum foil described in S1 is 0.1 mm, and the particle diameters of titanium powder and niobium powder are both 10-100 um. Others are the same as Embodiment 1.

specific Embodiment approach 3

[0046] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the niobium powder and titanium powder are mixed by ball milling as described in S1, the mixing time is 8h~16h, and the ball-to-material ratio is (15~20) : 1, the rotating speed of the ball mill is 100r / min~200r / min to obtain a uniformly mixed powder, wherein the volume fraction of pure titanium in the uniformly mixed powder is 85%~95%, and the volume fraction of niobium powder is 5% %~15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com