Method for performing ultrasonic alkaline leaching and microwave digestion combined treatment on electrolytic aluminum waste cathode carbon block

A waste cathode carbon block and microwave digestion technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problem that the environmental pollution of electrolytic aluminum waste cathode carbon block has not been effectively solved, the product added value is low, and the processing cost is high. problems, to achieve significant environmental benefits and economic benefits, improve microwave digestion efficiency, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

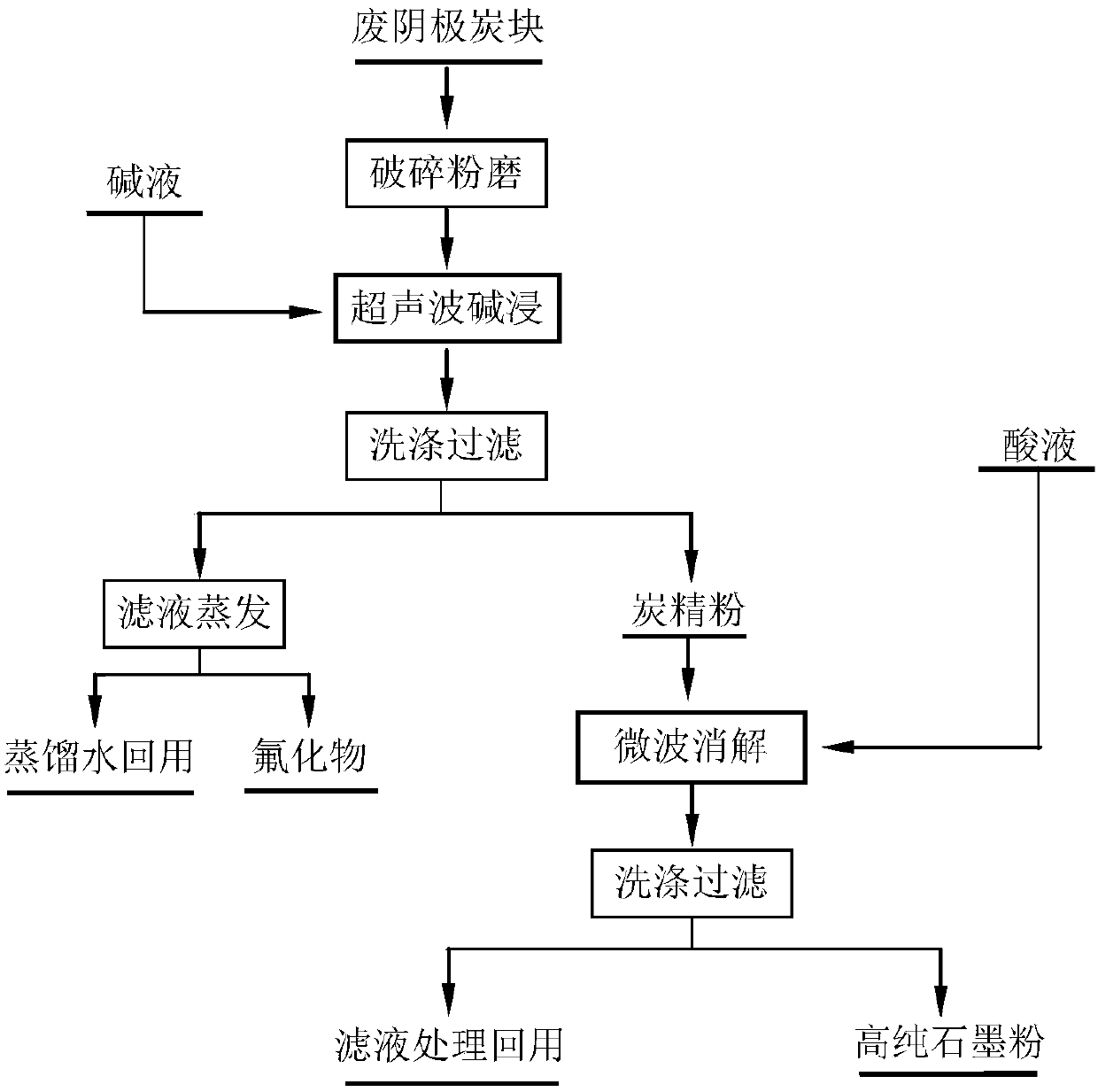

[0034] A method for combined treatment of electrolytic aluminum waste cathode carbon blocks by ultrasonic alkaline leaching and microwave digestion, the process flow of the method is as follows figure 1 As shown, the details are as follows:

[0035] (1) Crushing and grinding: First, the electrolytic aluminum waste cathode carbon block is crushed to a particle size of 2 cm, and then the electrolytic aluminum waste cathode carbon block with a particle size of 2 cm is ground into waste cathode carbon powder, waste cathode carbon The particle size in the powder is 0.075mm and accounts for 80wt%;

[0036] (2) Ultrasonic alkaline leaching: first add the waste cathode carbon powder obtained in step (1) into a sodium hydroxide solution with a mass fraction of 5% according to the mass volume ratio of 1:5 to obtain an alkaline slurry, and then the alkaline The slurry was ultrasonically treated at an ultrasonic frequency of 80kHz, a power of 400W, and a temperature of 30°C for 60 minute...

Embodiment 2

[0041] A method for combined treatment of electrolytic aluminum waste cathode carbon blocks by ultrasonic alkaline leaching and microwave digestion, the process flow of the method is as follows figure 1 As shown, the details are as follows:

[0042] (1) Crushing and grinding: First, the electrolytic aluminum waste cathode carbon block is crushed to a particle size of 2 cm, and then the electrolytic aluminum waste cathode carbon block with a particle size of 2 cm is ground into waste cathode carbon powder, waste cathode carbon The particle size in the powder is 0.075mm and accounts for 90wt%;

[0043] (2) Ultrasonic alkaline leaching: first add the spent cathode carbon powder obtained in step (1) into a sodium hydroxide solution with a mass fraction of 10% according to the mass-volume ratio of 1:5 to obtain an alkaline slurry, and then the alkaline The slurry was ultrasonically treated at an ultrasonic frequency of 40kHz, a power of 300W, and a temperature of 60°C for 30 minut...

Embodiment 3

[0048] A method for combined treatment of electrolytic aluminum waste cathode carbon blocks by ultrasonic alkaline leaching and microwave digestion, the process flow of the method is as follows figure 1 As shown, the details are as follows:

[0049] (1) Crushing and grinding: First, the electrolytic aluminum waste cathode carbon block is crushed to a particle size of 2 cm, and then the electrolytic aluminum waste cathode carbon block with a particle size of 2 cm is ground into waste cathode carbon powder, waste cathode carbon The particle size in the powder is 0.15mm and accounts for 80wt%;

[0050] (2) Ultrasonic alkaline leaching: first add the spent cathode carbon powder obtained in step (1) into a sodium hydroxide solution with a mass fraction of 10% according to the mass-volume ratio of 1:5 to obtain an alkaline slurry, and then the alkaline The slurry was ultrasonically treated at an ultrasonic frequency of 27kHz, a power of 500W, and a temperature of 80°C for 120 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com