Decontaminable water-permeable concrete and preparation method thereof

A technology of permeable concrete and cement, applied in the field of porous concrete, can solve the problems of large pores, low strength of ceramsite, and insufficient decontamination ability of permeable concrete, and achieve strong decontamination ability, high mechanical strength, and enhanced purification of runoff rainwater effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of decontamination permeable concrete of the present invention comprises the steps:

[0042] (10) Aggregate wetting: add all the aggregates including ceramsite and 50% water in the mixing device, stir for 30s, and make the surface of the aggregate wet;

[0043] (20) Mixing: Add all the cement, fly ash, reinforcing agent and water reducer to the aggregate with wet surface, and stir for 60 seconds to make it fully and evenly stirred;

[0044] (30) Discharging: add the remaining amount of water into the stirring device, stir evenly, charge in layers, insert and pound into shape, and cure to obtain decontamination and permeable concrete.

[0045] Preferably, in the (30) discharging step, each layer is inserted and rammed 30 times when the layered material is charged and rammed to form, and the spacing and strength are guaranteed to be uniform, and finally smoothed by hand.

[0046] Preferably, in the (30) discharging step, the maintenance is specific...

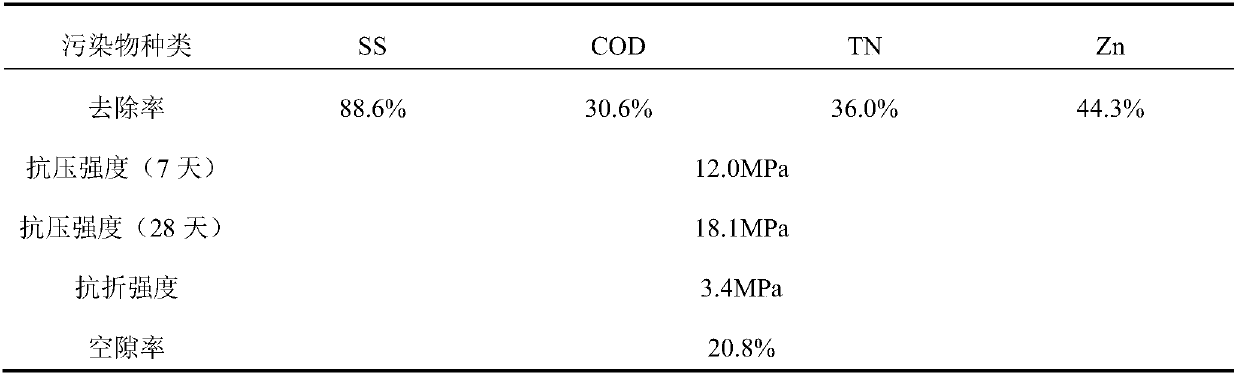

Embodiment 1

[0051] (1) Raw materials: aggregate 75%-80% (ceramsite replaces part of aggregate, aggregate replacement rate is 10%), cement 13%-17%, water 3%-6%, fly ash 1%-2 %, strengthening agent 0.34%-0.73%, superplasticizer 0.05%-0.09%. The cement used is ordinary Portland cement with P.O 42.5, and its property index meets the standard requirements; the aggregate is selected from Anhui basalt, and the apparent relative density is 2.870g / cm 3 , the particle size is 4.75mm-9.50mm; the water reducing agent is selected from Sika brand polycarboxylate high-efficiency water reducing agent of Jiangsu Temisi Concrete Admixture Co., Ltd.; the reinforcing agent is selected from Beijing Dechang Weiye special reinforcing agent for permeable concrete; Clay ceramsite with a particle size of 5-10mm produced by Zhejiang Huzhou Xinxiang Ceramic Products Co., Ltd. was selected.

[0052] (2) Preparation of decontamination and permeable concrete: ① Add all aggregates (including ceramsite instead of aggreg...

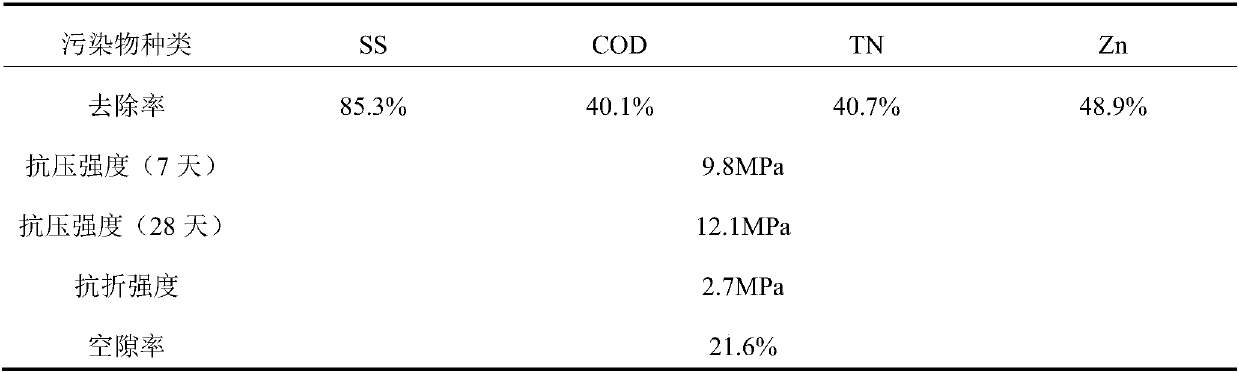

Embodiment 2

[0057] (1) Raw materials: aggregate 75%-80% (ceramsite replaces part of aggregate, aggregate replacement rate is 20%), cement 13%-17%, water 3%-6%, fly ash 1%-2 %, strengthening agent 0.34%-0.73%, superplasticizer 0.05%-0.09%. The materials used, the preparation, and the purification effect test are the same as in Example 1.

[0058] (2) The test results are shown in the table below:

[0059]

[0060]It can be seen from the test results of each embodiment that the present invention can reduce the amount of rainwater runoff, slow down the runoff velocity, and reduce the peak runoff coefficient of rainwater based on a large number of voids in pervious concrete, while the relationship between compressive strength, flexural strength and porosity of pervious concrete There is a relationship between compressive and flexural strengths that gradually decrease with the increase of porosity, and reinforcing agents are used in the preparation to ensure the strength of its performance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com