Preparation method of gamma-lactam bridging dipeptide compound

A technology of lactam bridge and compound, which is applied in the field of preparation of γ-lactam bridged dipeptide compounds, can solve the problems of reduced total yield of route, low yield of cyclization step, etc., and achieves avoiding the use of sulfide, The effect of high product yield and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

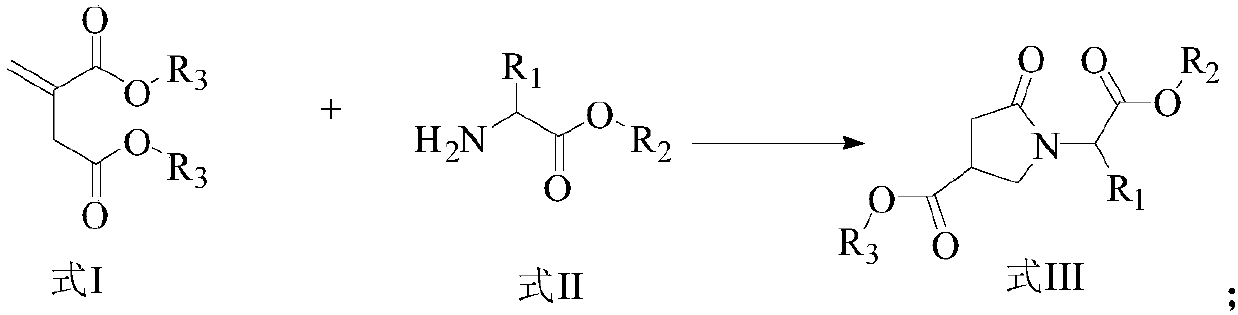

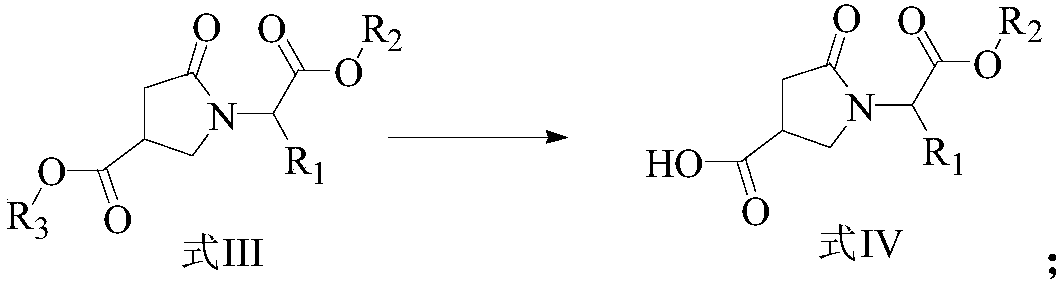

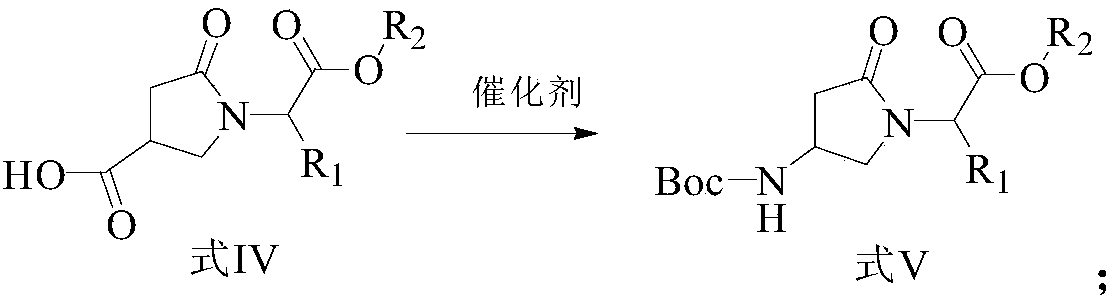

Method used

Image

Examples

Embodiment 1

[0056] In this example, the preparation process of 2-{4-[(tert-butoxy)carbonylamino]-2-oxopyrrolidinyl}acetic acid is as follows:

[0057]

[0058] The preparation method comprises the following steps:

[0059] Synthesis of tert-butyl 2-[4-(methoxycarbonyl)-2-oxopyrrolidinyl]acetate (3'):

[0060] Add 100ml of methanol, compound 1' (25g, 0.16mol, 1.0eq) and compound 2' (25g, 0.19mol, 1.2eq) into a 250ml three-necked flask, and reflux for 16h under nitrogen protection. The reaction is basically complete by TLC, spin-dried, Low-boiling impurities were distilled off under reduced pressure, and the residue was distilled to obtain compound 3' (38 g, yield 93%). MS-EI = 257.1. 1 H NMR (300MHz, CDCl 3 ): δ4.09-3.83 (m, 2H), 3.75-3.66 (m, 5H), 3.36-3.25 (m, 1H), 2.84-2.64 (m, 2H), 1.47 (s, 9H).

[0061] Synthesis of 1-{[(tert-butyl)oxycarbonyl]methyl}-5-oxopyrrolidine-3-carboxylic acid (4'):

[0062] Add 200ml of tetrahydrofuran and compound 3' (38g, 0.15mol, 1eq) into a 500ml...

Embodiment 2

[0068] In this example, the preparation process of (S)-2-methyl-2-{4-[(tert-butoxy)carbonylamino]-2-oxopyrrolidinyl}acetic acid is as follows:

[0069]

[0070] The preparation method comprises the following steps:

[0071] Synthesis of tert-butyl (S)-2-methyl-2-[4-(methoxycarbonyl)-2-oxopyrrolidinyl]acetate (8):

[0072] Add 100ml of methanol, compound 1' (22.7g, 0.14mol, 1.0eq) and compound 7 (24g, 0.168mol, 1.2eq) into a 250ml three-necked flask, and reflux for 16h under nitrogen protection. The reaction is basically complete by TLC, spin-dried, Low-boiling impurities were distilled under reduced pressure, and the residue was distilled to obtain compound 8 (28 g, yield 75%). MS-EI = 271.1. 1 H NMR (300MHz, CDCl3): δ4.82-4.72(m, 1H), 3.81-3.61(m, 5H), 3.36-3.19(m, 1H), 2.84-2.63(m, 2H), 1.46(s, 9H), 1.42-1.37 (m, 3H).

[0073] Synthesis of (S)-1-{1-[(tert-butyl)oxycarbonyl]ethyl}-5-oxopyrrolidine-3-carboxylic acid (9):

[0074] Add 200ml of tetrahydrofuran and compou...

Embodiment 3

[0080] In this example, the preparation process of (S)-2-(2-methylpropyl)-2-{4-[(tert-butoxy)carbonylamino]-2-oxopyrrolidinyl}acetic acid is as follows :

[0081]

[0082] The preparation method comprises the following steps:

[0083] Synthesis of tert-butyl (S)-2-(2-methylpropyl)-2-[4-(methoxycarbonyl)-2-oxopyrrolidinyl]acetate (13):

[0084] Add 100ml of methanol, compound 1' (16.8g, 0.11mol, 1.0eq), compound 12 (31.32g, 1.5eq, 0.165mol) into a 250ml three-necked flask, and reflux for 16h under nitrogen protection. The reaction is basically complete by TLC, and spin-dried , Low-boiling impurities were distilled off under reduced pressure, and the residue was distilled to obtain compound 13 (28.8 g, yield 82%). MS-EI=313. 1H NMR (300MHz, CDCl3): δ4.69(t, 1H), 3.83-3.67(m, 4H), 3.51(t, 1H), 3.24-3.12(m, 1H), 2.78-2.57(m, 2H) , 1.70-1.56 (m, 2H), 1.41 (s, 10H), 0.93-0.88 (m, 6H).

[0085] Synthesis of (S)-1-{1-[(tert-butyl)oxycarbonyl]-3-methylpropyl}-5-oxopyrrolidine-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com