A high-efficiency green pretreatment method and application for improving lignocellulose enzymatic hydrolysis and saccharification efficiency

A lignocellulosic and pretreatment technology, applied in the direction of biofuel, fermentation, etc., to achieve the effect of improving the efficiency of enzymatic hydrolysis and saccharification, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

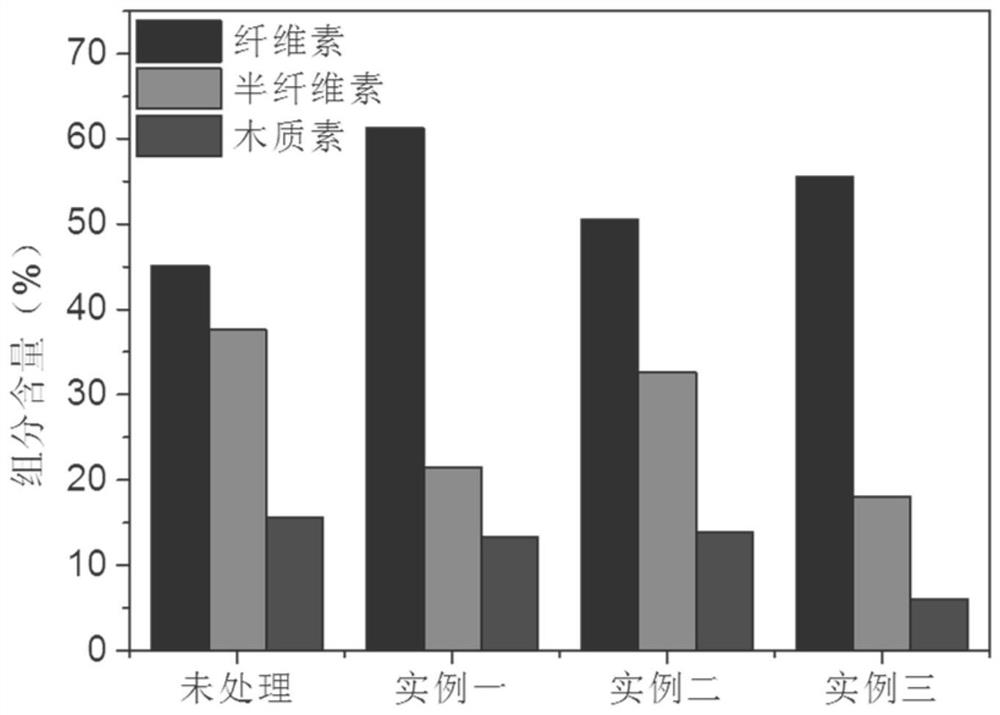

Embodiment 1

[0020] ( ) The rice straw is dried and crushed, and the particle size is controlled to be 180-425 μm;

[0021] ( ) Mix citric acid, choline chloride, and glycerol at a molar ratio of 0.5:1:1.5, put them in a shaker at 100 ℃, and wait until a completely fused colorless and transparent liquid is formed, take it out for use;

[0022] ( ) into rice straw at a content of 10% (W / W), adding the above ( ) in eutectic solvent, add 5% (W / W) distilled water and vibrate and mix in a shaker at 130 ℃ for 4 hours after pretreatment, filter and wash the filter residue with distilled water until the pH of the cleaning solution is neutral. The filtered residue was dried at 55°C to obtain NADES-treated rice straw samples;

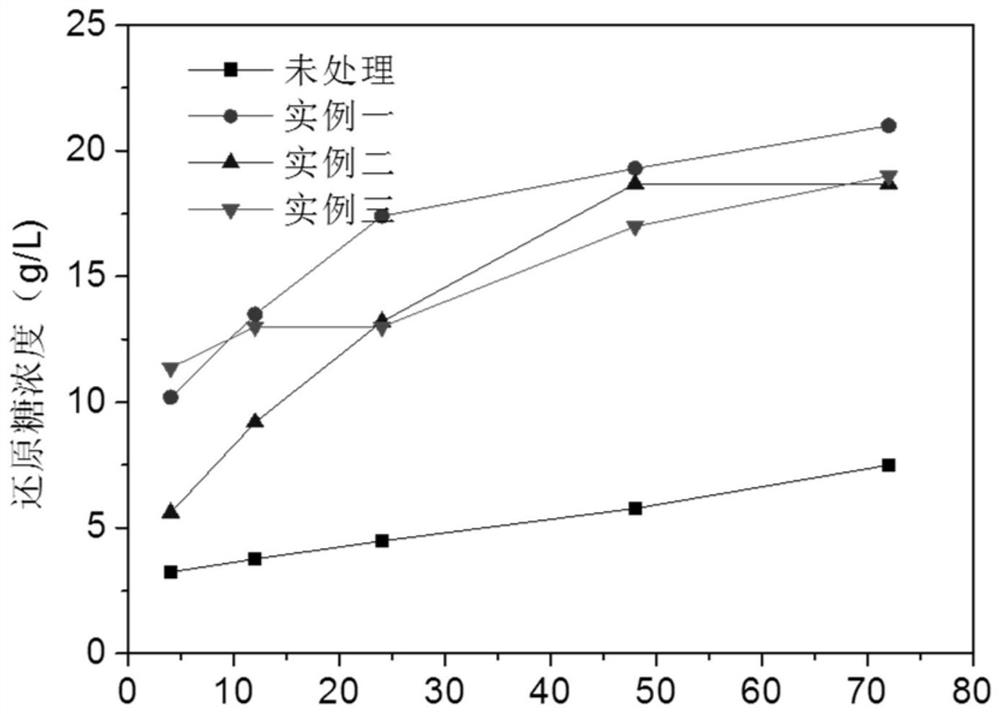

[0023] ( ) The rice straw sample pretreated by NADES was mixed with citrate buffer (0.1 mol / L, pH 4.8) at a concentration of 25 mg / mL, and then 12 FPU / g substrate cellulase was added, at 50 After enzymatic hydrolysis for 72 h under the conditions of ℃ and 100 rpm / m...

Embodiment 2

[0026] ( ) The rice straw is dried and crushed, and the particle size is controlled to be 180-425 μm;

[0027] ( ) Mix citric acid, choline chloride, and glycerol at a molar ratio of 1:1:1, place in a shaker at 100 °C, and wait until a completely fused colorless and transparent liquid is formed, take it out for use;

[0028] ( ) into rice straw at a content of 10% (W / W), adding the above ( ) in eutectic solvent, add 5% (W / W) distilled water and vibrate and mix in a shaker at 130 ℃ for 4 hours after pretreatment, filter and wash the filter residue with distilled water until the pH of the cleaning solution is neutral. The filtered residue was dried at 55°C to obtain NADES-treated rice straw samples;

[0029] ( ) The rice straw sample pretreated by NADES was mixed with citrate buffer (0.1 mol / L, pH 4.8) at a concentration of 25 mg / mL, and then 12 FPU / g substrate cellulase was added, at 50 After enzymatic hydrolysis for 72 h under the conditions of ℃ and 100 rpm / min, the ...

Embodiment 3

[0032] (a) Rice straw is dried and crushed, and the particle size is controlled to be 180-425 μm;

[0033] ( ) Mix citric acid, choline chloride, and glycerol at a molar ratio of 0.5:1:1.5, put them in a shaker at 100 ℃, and wait until a completely fused colorless and transparent liquid is formed, take it out for use;

[0034] (c) Add rice straw at a content of 10% (W / W), add the above ( ) in eutectic solvent, add 5% (W / W) distilled water and vibrate and mix in a shaker at 130 ℃ for 3 hours after pretreatment, filter and wash the filter residue with distilled water until the pH of the cleaning solution is neutral. The filtered residue was dried at 55°C to obtain NADES-treated rice straw samples;

[0035] ( ) The rice straw sample pretreated by NADES was mixed with citrate buffer (0.1 mol / L, pH 4.8) at a concentration of 25 mg / mL, and then 12 FPU / g substrate cellulase was added, at 50 After enzymatic hydrolysis for 72 h under the conditions of ℃ and 100 rpm / min, the enzy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com