Preparation method of porous silicon carbon negative electrode applicable to lithium ion battery

A technology for carbon negative electrode materials and lithium-ion batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of large specific surface area of porous silicon, reduced battery reversible capacity, low Coulombic efficiency, etc., to achieve lower specific surface area, better Market potential, the effect of simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

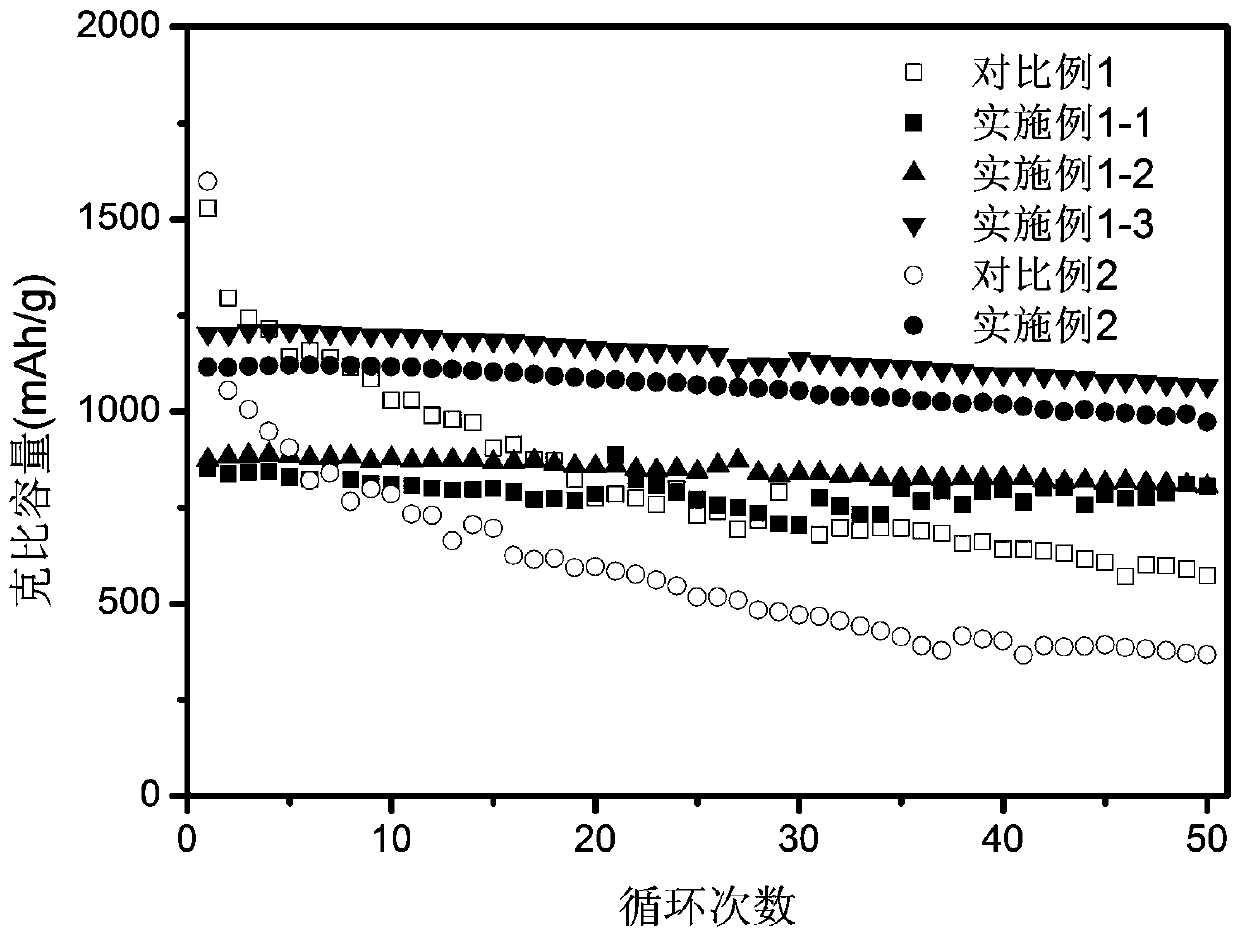

[0046] Weigh 30 g of porous silicon with a medium particle size of about 3 microns and a porosity of about 85%, add it to 400 g of a 30% starch solution, and stir evenly. The material was pulverized after vacuum drying at 70°C for 12 hours. After mixing 150 g of the pulverized material with 30 g of pitch, it was heated to 300° C. while stirring under a nitrogen atmosphere and kept for 1.5 hours. The heat-treated material was pulverized and carbonized by heating to 1000° C. for 6 hours under a nitrogen atmosphere. The material obtained after carbonization is pulverized and passed through a 325-mesh sieve to obtain the final material.

[0047] The material was prepared into a 2032 button battery, and the electrochemical performance was tested by a constant current on a charge-discharge tester. The charge-discharge current was set to 150mA / g, and the voltage range was 0.01-2V. The first coulombic efficiency of the corresponding lithium-ion battery was determined to be 80.6%, an...

Embodiment 1-2

[0049] Weigh 30 g of porous silicon with a medium particle size of about 3 microns and a porosity of about 85%, add it to 300 g of 30% starch solution, and stir evenly. The material was pulverized after vacuum drying at 70°C for 12 hours. After mixing 150 g of the pulverized material with 40 g of pitch, it was heated to 300° C. while stirring under a nitrogen atmosphere and kept for 1.5 hours. The heat-treated material was pulverized and carbonized by heating to 1000° C. for 6 hours under a nitrogen atmosphere. The material obtained after carbonization is pulverized and passed through a 325-mesh sieve to obtain the final material.

[0050] The material was prepared into a 2032 button battery, and the electrochemical performance was tested by a constant current on a charge-discharge tester. The charge-discharge current was set to 150mA / g, and the voltage range was 0.01-2V. The first coulombic efficiency of the corresponding lithium-ion battery was determined to be 83.2%, and ...

Embodiment 1-3

[0052] Weigh 30 g of porous silicon with a medium particle size of about 3 microns and a porosity of about 85% and add it to 400 g of 30% sucrose solution and stir evenly. The material was pulverized after vacuum drying at 70°C for 12 hours. After mixing 150 g of the pulverized material with 30 g of pitch, it was heated to 300° C. while stirring under a nitrogen atmosphere and kept for 1.5 hours. The heat-treated material was pulverized and carbonized by heating to 1000° C. for 6 hours under a nitrogen atmosphere. The material obtained after carbonization is pulverized and passed through a 325-mesh sieve to obtain the final material.

[0053] The material was prepared into a 2032 button battery, and the electrochemical performance was tested by a constant current on a charge-discharge tester. The charge-discharge current was set to 150mA / g, and the voltage range was 0.01-2V. The first coulombic efficiency of the corresponding lithium-ion battery was determined to be 76.9%, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com