A kind of cross-linked gel polymer electrolyte and preparation method thereof

A cross-linked gel and polymer technology, which is applied in the field of lithium-ion batteries, can solve the problems of affecting the performance of polymer electrolytes, low porosity and liquid absorption, and hindering battery performance. The effect of high rate and liquid absorption and reduced crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

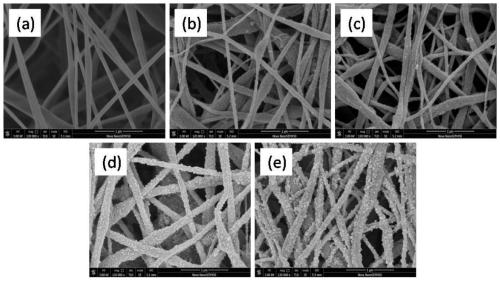

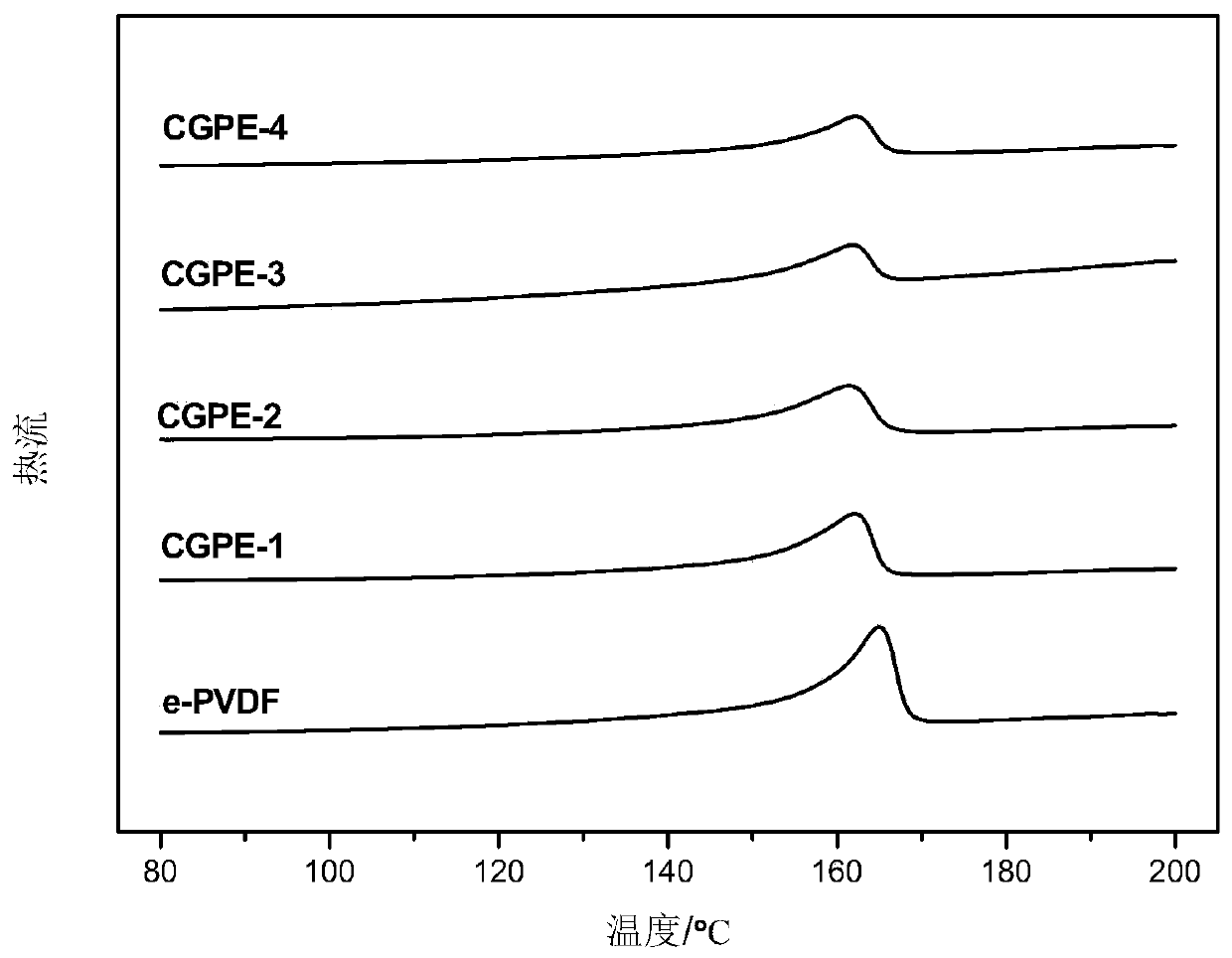

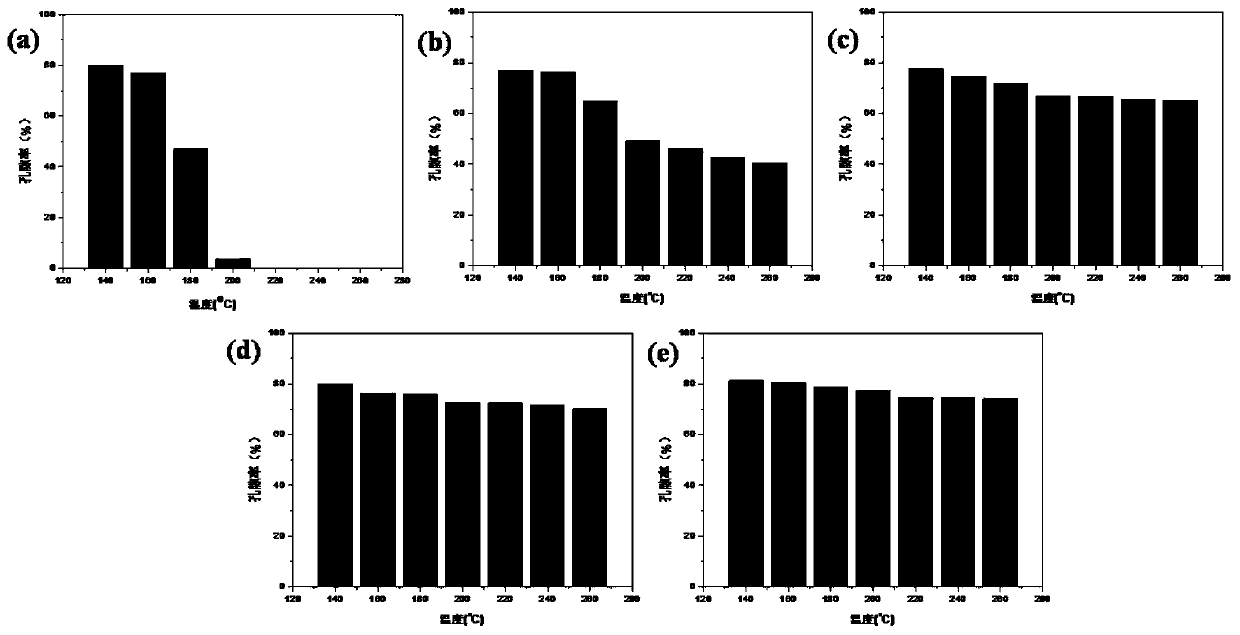

Method used

Image

Examples

Embodiment 1

[0045] P.S. 25 -PEO-PS 25 Addition is the preparation of the cross-linked gel polymer electrolyte of 20%, comprises the steps:

[0046] 1) Preparation of Br-PEO-Br macroinitiator:

[0047] Dissolve 8.8g of PEO in 130mL of dichloromethane, stir to dissolve and add 4.64mL of triethylamine (TEA); add 20mL of dichloromethane into another anhydrous and oxygen-free container, and dissolve 4.14mL of BIBB in it; Under the condition of about ℃, slowly add the dichloromethane solution of BIBB into the first container, then raise the temperature to 25~35℃, and stir for 15~20h; after the reaction, filter off the triethylamine bromate formed by triethylamine , and then use saturated sodium bicarbonate (NaHCO 3 ) and water were washed multiple times to remove unreacted BIBB in the system; then add a large amount of Na 2 SO 4 Dry to remove residual moisture in the system; filter out Na 2 SO 4 Finally, a large amount of DCM solvent was removed by evaporation, and then settled in ether ...

Embodiment 2

[0055] P.S. 50 -PEO-PS 50 Addition is the preparation of the cross-linked gel polymer electrolyte of 20%, comprises the steps:

[0056] 1) the preparation of Br-PEO-Br macroinitiator: concrete method is with the step 1) of embodiment 1);

[0057] 2)PS 50 -PEO-PS 50 Preparation of tri-block copolymer: under anhydrous and oxygen-free conditions, add 4g Br-PEO-Br, 0.14g CuBr and 20mL dioxane, stir and dissolve, then add 5.71mL St, then add 0.31mL PMDETA, in Stir at a temperature of 100-120°C for 12-36 hours; after the reaction is completed, dilute the reaction solution with tetrahydrofuran, preferably use a short column of basic alumina to remove copper salts, evaporate a large amount of THF solvent, settle and precipitate in n-hexane, and bake dry get PS 50 -PEO-PS 50 triblock copolymer.

[0058] 3) Preparation of cross-linked gel polymer electrolyte 2:

[0059] Electrospinning: At room temperature, 0.4 g triblock copolymer PS 50 -PEO-PS 50 And 1.6g PVDF was dissolved ...

Embodiment 3

[0063] P.S. 100 -PEO-PS 100 20% PVDF / PS added 100 -PEO-PS 100 The preparation of cross-linked gel polymer electrolyte comprises the steps:

[0064] 1) the preparation of Br-PEO-Br macroinitiator: concrete method is with the step 1) of embodiment 1);

[0065] 2)PS 100 -PEO-PS 100 Preparation of tri-block copolymer: under anhydrous and oxygen-free conditions, add 4g Br-PEO-Br, 0.14g CuBr and 20mL dioxane, stir and dissolve, then add 11.4mL St, then add 0.31mLPMDETA, at 100 Stir at a temperature of ~120°C for 12-36 hours; after the reaction is completed, dilute the reaction solution with tetrahydrofuran, preferably use a short column of basic alumina to remove copper salts, evaporate a large amount of THF solvent, settle and precipitate in n-hexane, and dry get PS 100 -PEO-PS 100 triblock copolymer.

[0066] 3) Preparation of cross-linked gel polymer electrolyte 3:

[0067] Electrospinning: At room temperature, 0.4 g triblock copolymer PS 100 -PEO-PS 100 And 1.6g PVDF...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com