Precious metal low-load catalyst for VOCs (volatile organic chemicals) catalytic combustion and preparation method

A catalyst and precious metal technology, which is applied in the field of catalysts with low loading of precious metals and their preparation, can solve problems such as restricting the use of catalysts, achieve good catalytic combustion performance, reduce usage, and have significant technical effects and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

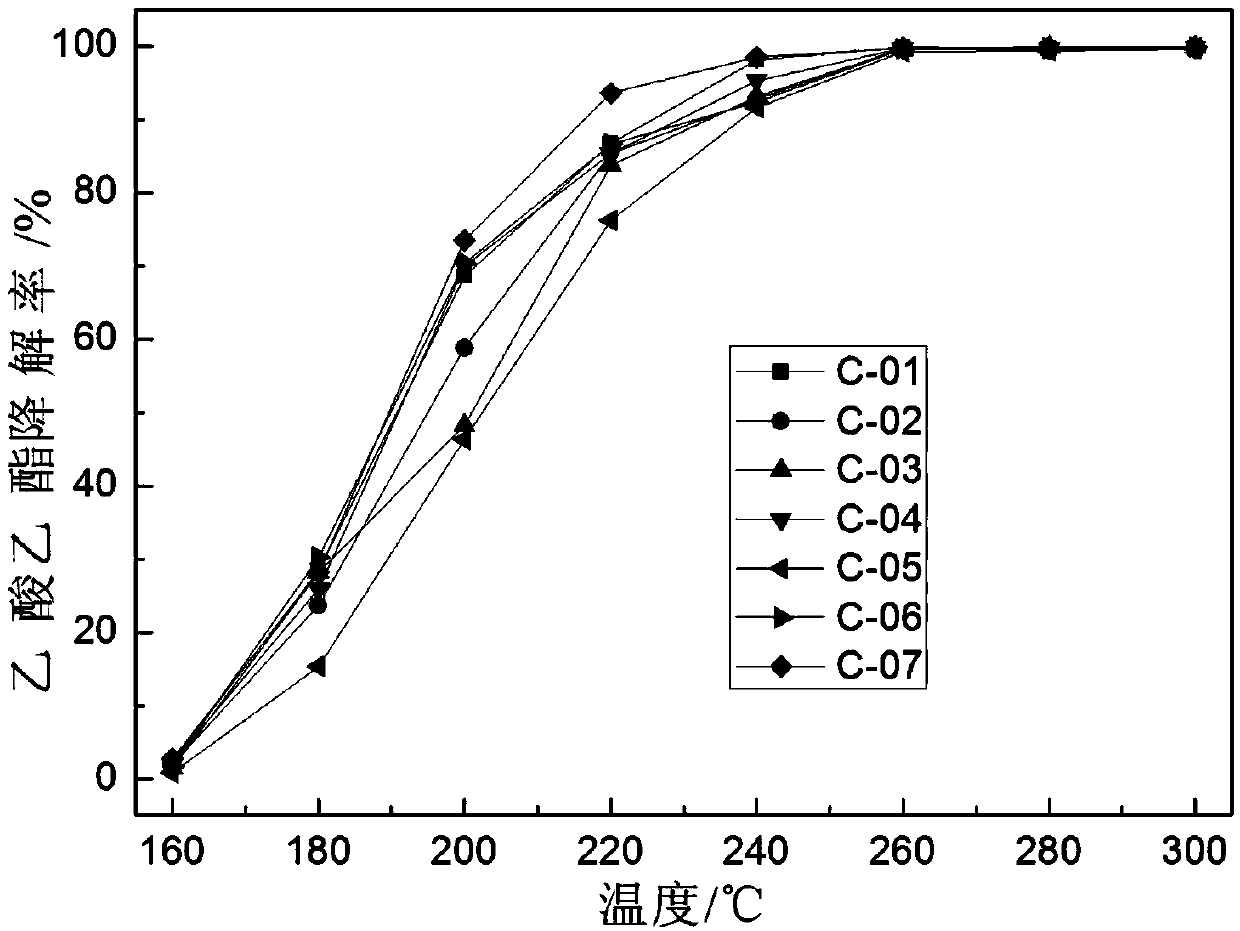

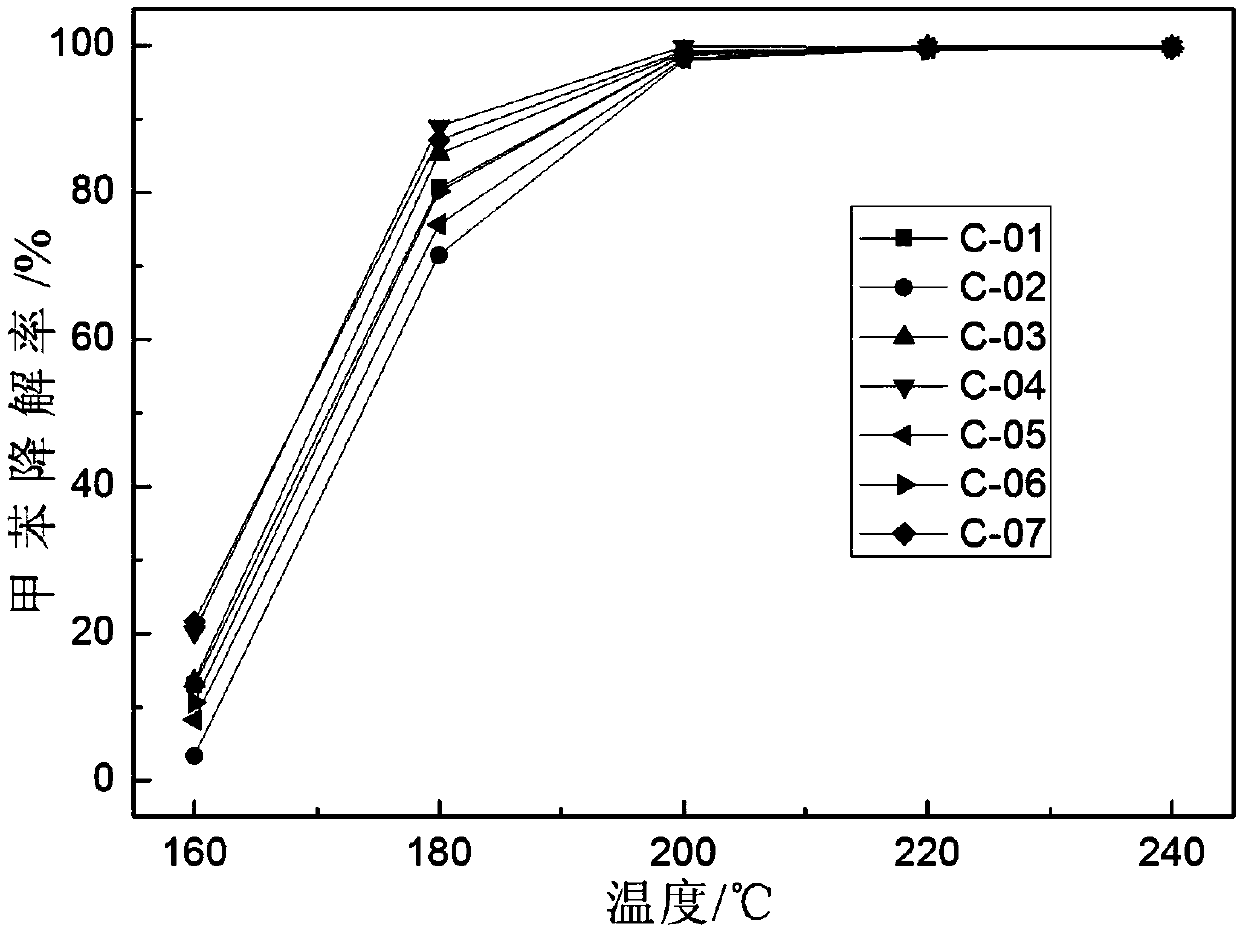

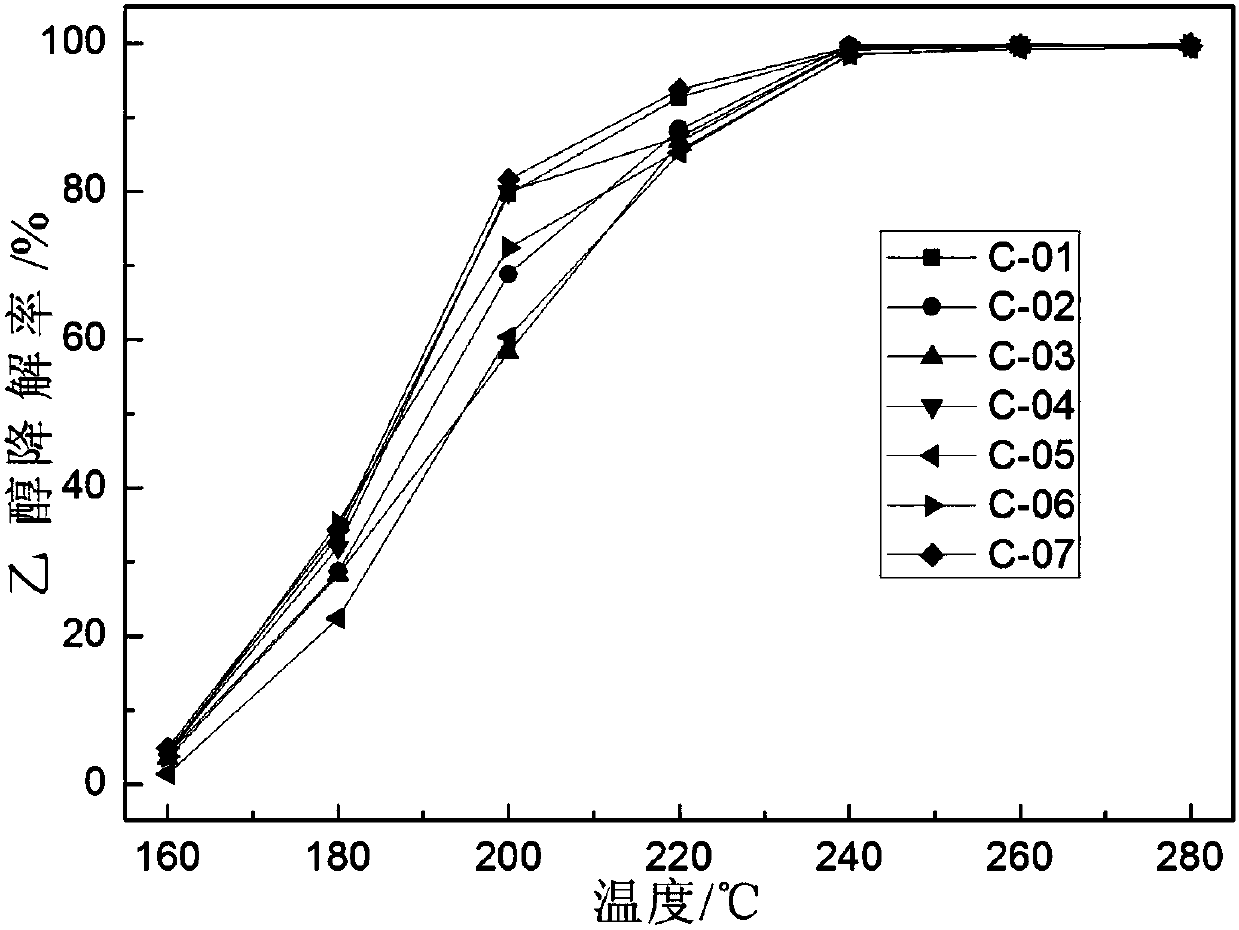

Examples

Embodiment 1

[0020] Embodiment 1 (dipping method)

[0021] Solution preparation: Weigh 3.3292g of palladium chloride to prepare a 100mL solution; weigh CuCl 2 2H 2 O 26.63g, was prepared into 100mL solution; weighed lithium chloride 12.21g, was prepared into 100mL solution.

[0022] Weigh 30.03 g of spherical alumina carrier (alumina bulk density 0.75 g / mL) and place it in a dipping bottle.

[0023] Add 0.40mL Pd solution, 2.00mL Cu solution, 0.75mL Li solution and 6.85mL purified water into the mixer and mix well.

[0024] Add the mixed impregnation solution into the impregnation bottle to impregnate the carrier for 1 hour; transfer the impregnated catalyst to an oven at 120°C for 4 hours; transfer the dried catalyst to a muffle furnace for calcination at 450°C for 5 hours to prepare catalyst C-01 (Pd: 200g / m 3 ; Cu: 5000g / m 3 ; Li: 375g / m 3 ).

Embodiment 2

[0025] Embodiment 2 (active component coating method)

[0026] Solution preparation: take by weighing palladium chloride 3.3298g, be mixed with 100mL solution; Measure mass concentration and be 50% Mn(NO 3 ) 2 Solution (1.54g / ml) 42.25mL, diluted to 100mL; weigh Mg(NO 3 ) 2 ·6H 2 O 21.36g, prepared into 100mL solution.

[0027] Weigh 27.98g of cordierite honeycomb ceramics (bulk density 0.70g / mL), soak in dilute acid, dry and roast, and set aside. Coating the alumina sol slurry on the surface of the carrier to be used, and obtaining the cordierite honeycomb ceramics loaded with alumina coating after firing, controlling the concentration and coating amount of the alumina sol slurry so that the alumina coating accounts for 10 wt% of the carrier weight, ready for use.

[0028] Add 0.20mL of Pd solution, 1.20mL of Mn solution, 2.00mL of Mg solution and 6.60mL of purified water into a mixer and mix evenly to obtain a coating solution.

[0029] Coat the coating solution on the...

Embodiment 3

[0030] Embodiment 3 (active component coating method)

[0031] Solution preparation: Weigh 5.3097g of chloroplatinic acid to make 100mL solution; weigh Ce(NO 3 ) 3 ·6H 2 O 31.00g, prepared into 100mL solution; Weigh 5.0895g of sodium chloride, prepared into 100mL solution.

[0032] Weigh 28.03g of cordierite honeycomb ceramics, dry and roast after dilute acid treatment, and set aside. Coating the alumina sol slurry on the surface of the carrier to be used, and obtaining the cordierite honeycomb ceramics loaded with alumina coating after firing, controlling the concentration and coating amount of the alumina sol slurry so that the alumina coating accounts for 10 wt% of the carrier weight, ready for use.

[0033] Add 0.20mL of Pt solution, 0.60mL of Ce solution, 0.30mL of Na solution and 8.90mL of purified water into a mixer and mix evenly to obtain a coating solution.

[0034] Coat the coating solution on the alumina coating of the carrier and let it stand for 6 hours; tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com